Composition for slag formation and preparation and use method thereof

A composition and a slag-forming technology, which are applied in the field of compositions for slag-making, can solve the problems of complex process and high energy consumption, and achieve the effects of simple process, low energy consumption and remarkable phosphorus reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

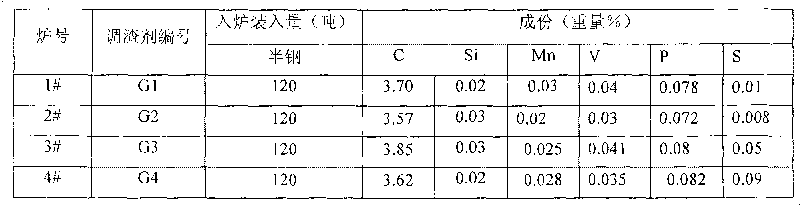

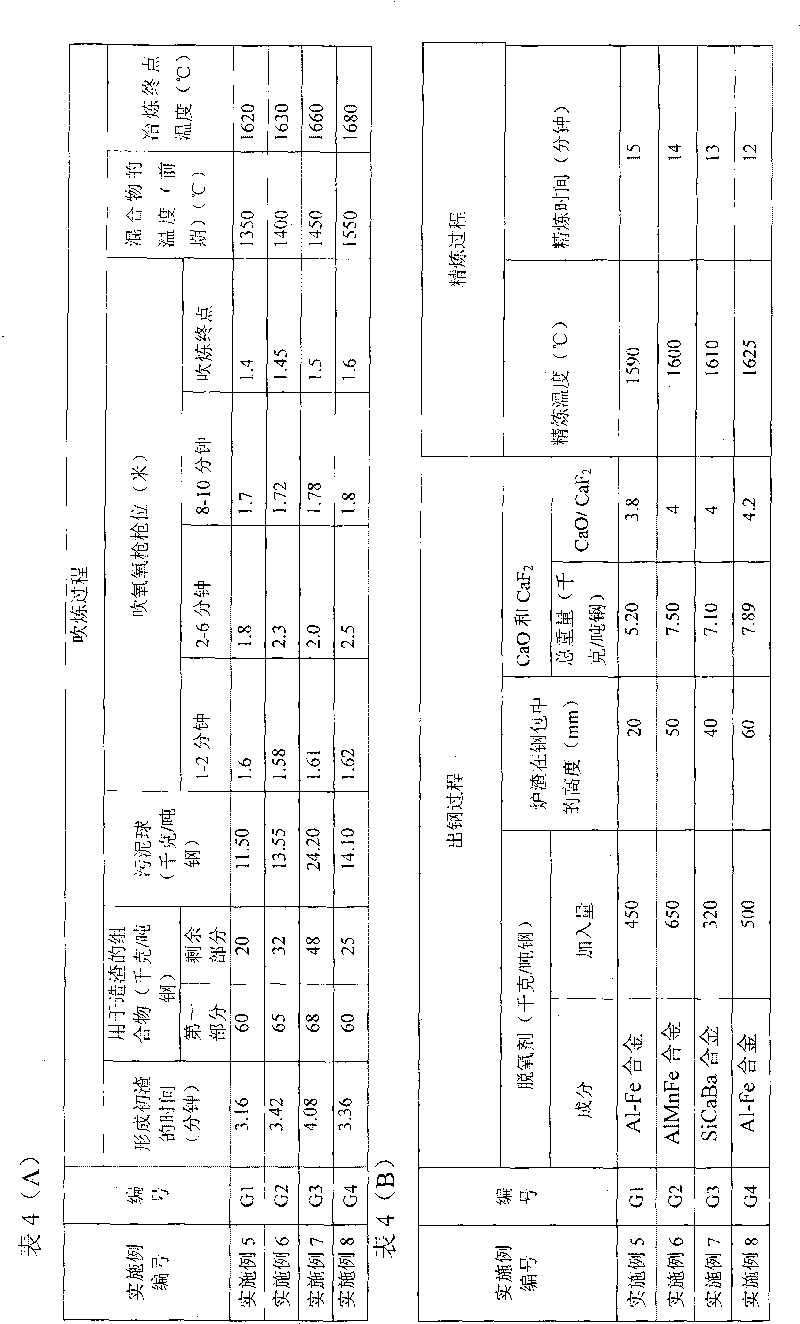

Examples

preparation example Construction

[0011] The present invention also provides the preparation method of said composition, wherein, the method comprises CaO, SiO 2 , MnO, MgO and Al 2 o 3 Mix evenly, CaO, SiO 2 , MnO, MgO and Al 2 o 3 The amount of addition makes the formed mixture contain, based on the total weight of the mixture, 45-65% by weight of CaO, 10-20% by weight of SiO 2 , 1-5% by weight of MnO, 9-25% by weight of MgO and 1.5-5% by weight of Al 2 o 3 .

[0012] The CaO can be derived from various materials containing calcium oxide, for example, it can be derived from one or more of manganese ore, lime, light-burned dolomite and composite slagging agent, preferably from lime, light-burned dolomite and composite slagging agent agent; the SiO 2 Can be derived from sludge balls, and composite slagging agent, preferably derived from composite slagging agent; the magnesium oxide can be derived from one or Several, preferably from light burnt dolomite. Manganese oxide can be derived from various ma...

Embodiment 1

[0026] This example is used to illustrate the composition for slagging provided by the present invention.

[0027] 43 parts by weight of lime, 26 parts by weight of lightly burned dolomite and 19 parts by weight of composite slagging agent were uniformly mixed to prepare composition G1 for slagging. The weight ratio of lime, lightly burned dolomite and composite slagging agent is 1:0.6:0.44. CaO, SiO in composition G1 for slagging 2 、Al 2 o 3 The contents of , MgO and MnO in the composition used for slagging are shown in Table 2.

Embodiment 2

[0029] This example is used to illustrate the composition for slagging provided by the present invention.

[0030] 42 parts by weight of lime, 33 parts by weight of lightly burned dolomite and 25 parts by weight of composite slagging agent were uniformly mixed to prepare composition G2 for slagging. The weight ratio of lime, lightly burned dolomite and composite slagging agent is 1:0.8:0.6. CaO, SiO in composition G2 for slagging 2 、Al 2 o 3 The contents of , MgO and MnO in the composition used for slagging are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com