Converter-strengthened slagging agent and preparation method and using method thereof

A slag agent and converter technology, applied in the field of converter strengthened slag agent and its preparation, can solve the problems of excessive phosphorus content at the end point, long time for slag removal, and difficulty in dephosphorization, so as to reduce the amount of alloy, shorten the time for slag removal, Improvement of slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

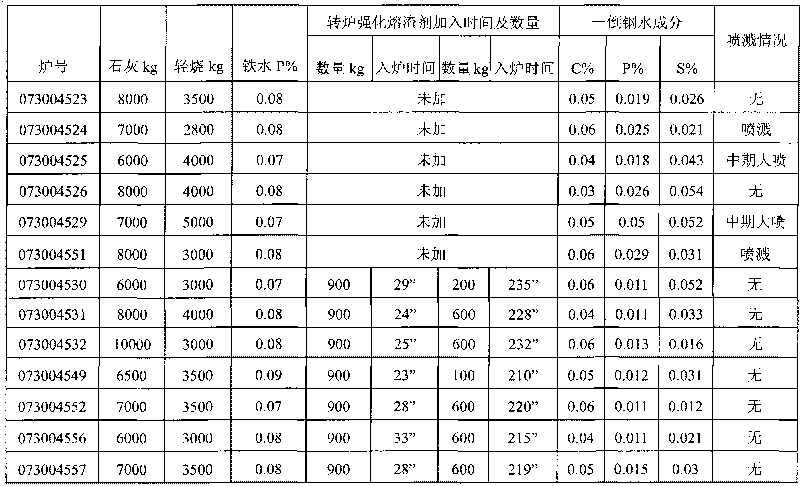

[0035] During the smelting process of a 150-ton converter in a certain factory, a comparative test was carried out with and without converter-enhanced slag, and the test data are shown in Table 1.

[0036] Table 1: Comparison of the smelting situation between the slag agent heat and the unused heat using the converter

[0037]

[0038] Through data comparison, the advantages of adding converter to strengthen slag agent are:

[0039] 1. The converter strengthened slag agent has good metallurgical properties, can quickly form slag, and slag is 1'~1.5' ahead of time; it can melt slag throughout the process, basically does not splash, does not "return to dry", and does not stick to the gun; it is beneficial to safe production, Reduce steel consumption.

[0040] 2. The smelting is stable, the production is smooth, the smelting cycle is shortened, and it is beneficial to increase the steel output.

[0041] 3. The dephosphorization rate of the converter is greatly improved, and ...

Embodiment 2

[0043] It is used in a 70-ton converter in a certain factory. The amount of converter strengthening slag agent added is 5-10kg / t steel. The addition method is to add 300kg within 30 seconds of starting blowing, and add 100-200kg again 3-5 minutes after starting blowing, and oxygen is supplied to the converter. The method and feeding method are carried out according to the original operating procedure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com