Pressure and water reduction construction method of ultra-deep foundation pit confined water

A construction method and technology for confined water, which are applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of water permeability damage to the hole wall, deep influence of dewatering wells, and inability to achieve decompression and precipitation. The total drainage volume, the precipitation effect is excellent, and the effect of reducing the impact range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

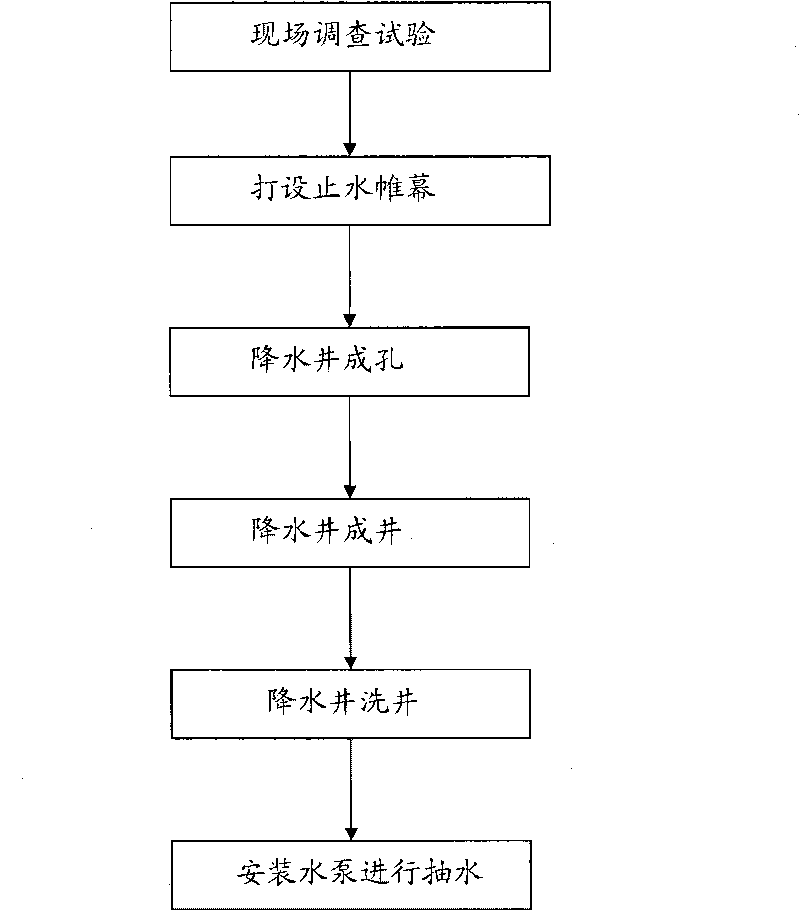

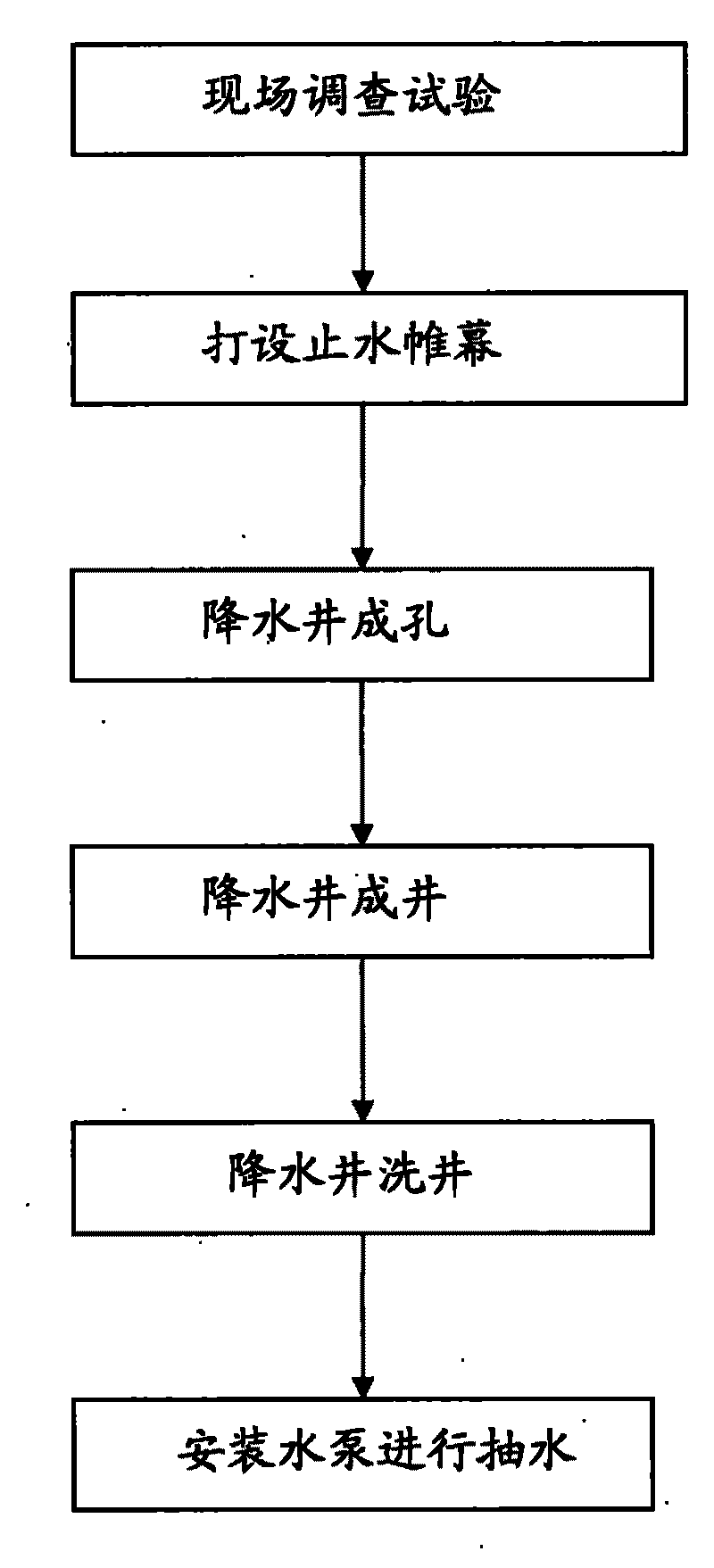

[0017] Such as figure 1 As shown in the figure, it discloses the schematic flow chart of the decompression and dewatering construction method of the ultra-deep foundation pit pressurized water provided by the present invention. The implementation steps of the decompression and dewatering construction method include: first conducting on-site investigation and testing, and then setting up the water-stop curtain, And carry out the drilling, well-forming and well-washing operations of the dewatering well, and then install the water pump to pump water and start the official operation.

[0018] In the field investigation and test steps, the investigation will be carried out at the planned construction site first to find out the geological formation age, formation characteristics, composition and particles and other relevant physical property indicators, as well as the dynamics of the confining aquifer of the round gravel layer Change characteristics, and understand the hydrogeology ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com