Roof wall surface heat insulation building material and manufacturing method thereof

A manufacturing method and technology of building materials, applied in the direction of roofing, building structure, chemical instruments and methods, etc., can solve the problems of poor heat insulation effect, large investment in setting up factories, difficult plastic foam, etc., achieve small thermal conductivity, small investment, The effect that the manufacturing method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

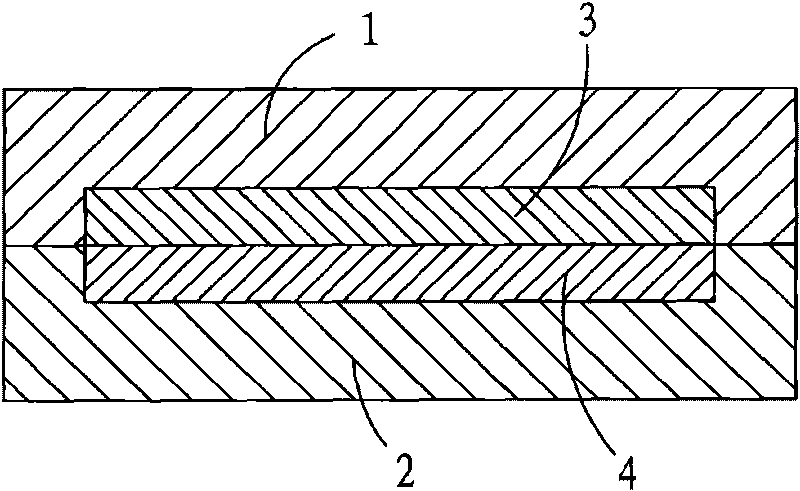

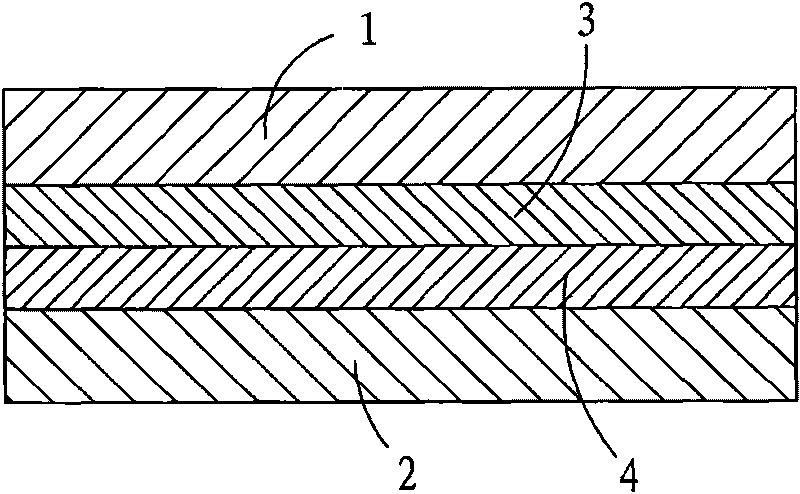

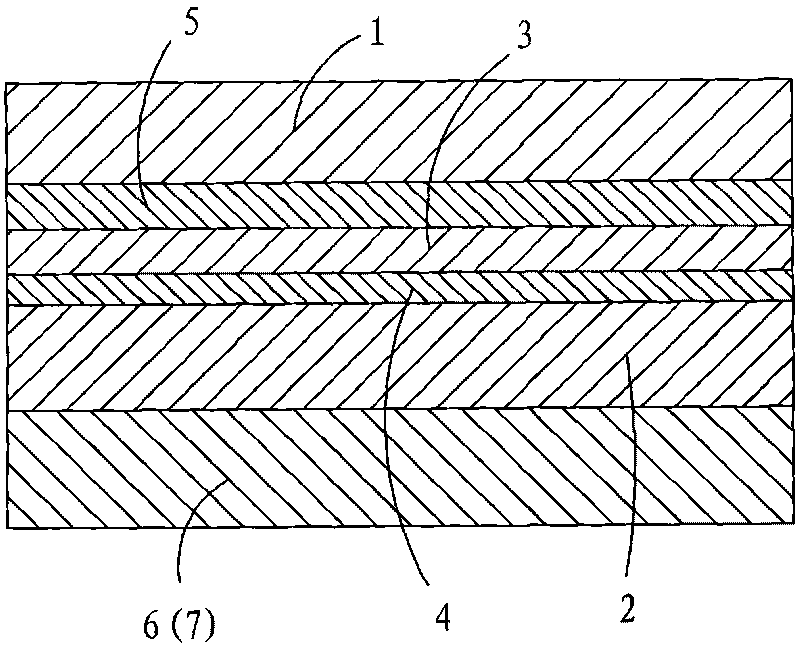

[0039] see figure 1 As shown, a roof and wall insulation building material, the heat insulation building material includes a surface layer 1, a base layer 2, at least one layer of reflective material layer 3 is arranged between the surface layer 1 and the base layer 2, the reflection There is also at least one heat insulating layer 4 between the material layer 3 and the primer layer 2 .

[0040] The reflective material layer 3 is a polyester film coated with reflective metal material on both sides or aluminum foil, and the reflective metal material coated on the polyester film is one of aluminum, silver, chrome or zinc. The secondary insulation layer 4 is one of recycled fiber, rock wool, asbestos, glass fiber cloth, and quartz fiber cloth. The surface layer 1 is a cement mortar layer, the base layer 2 is a cement concrete layer, and the reflective material layer 3 and the secondary heat insulation layer 4 are completely encapsulated in the space surrounded by the cement mort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com