Method and device for inversely controlling fuzzy compensation of radial position of bearing-free synchronous reluctance motor

A synchronous reluctance motor, fuzzy compensation technology, applied in the direction of motor generator control, AC motor control, control of electromechanical transmission devices, etc., can solve the problem that the PID controller parameters are difficult to adjust in real time, affect the running performance of the suspension system, and the control effect is poor, etc. problem, to achieve excellent decoupling effect, easy implementation, and the effect of enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

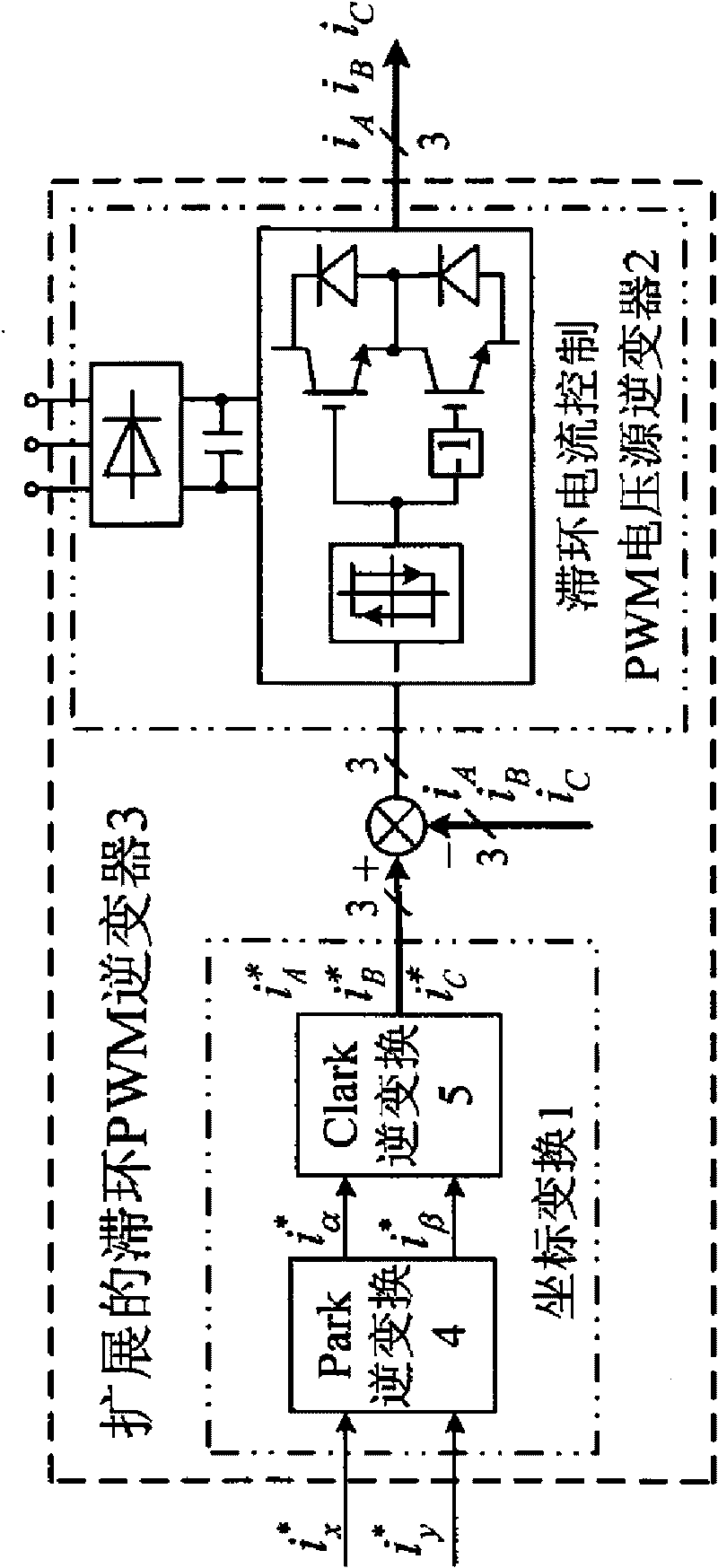

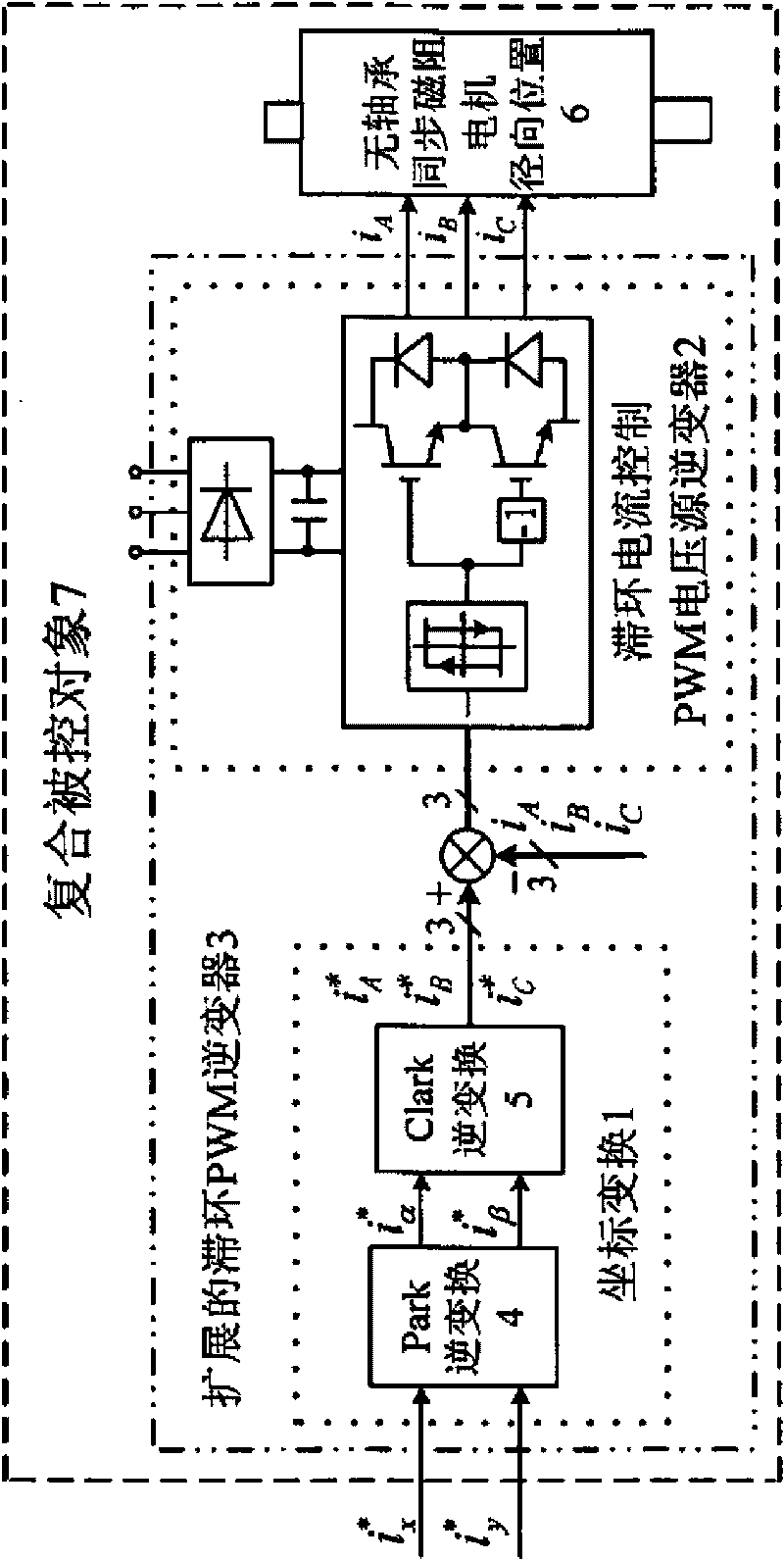

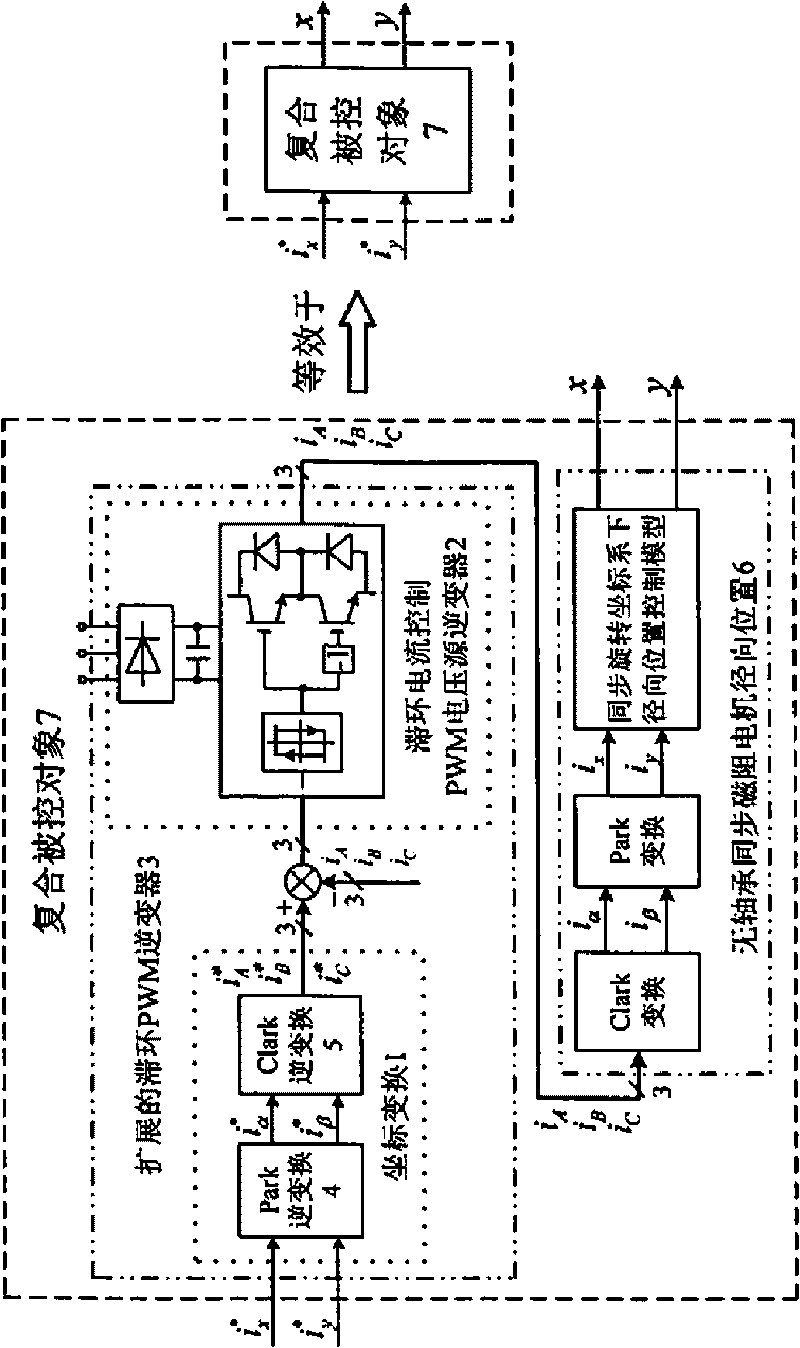

[0039] Technical scheme of the present invention is summarized as follows:

[0040] Construct a bearingless synchronous reluctance motor radial position fuzzy compensation inverse control device, the control method of the device includes the following steps: first, a hysteresis current is used to control a PWM voltage source inverter, a Park inverse transform and a Clark inverse transform together to form a Extended hysteresis-loop PWM inverter; then the radial position of the controlled bearingless synchronous reluctance motor and the extended current hysteresis-loop PWM inverter are composed of a composite controlled object, and the controlled quantities of the composite controlled object are two Radial position; Next, build the inverse system of the compound controlled object to realize the decoupling function of the inverse system of the compound controlled object; place the inverse system in front of the compound controlled object, and the inverse system and the compound c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com