Improved smoke removal purifier

A technology of purification device and purification tower, which is applied in the field of flue gas desulfurization device and improved exhaust purification device, to achieve the effect of reducing sulfate content and eliminating sulfate rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

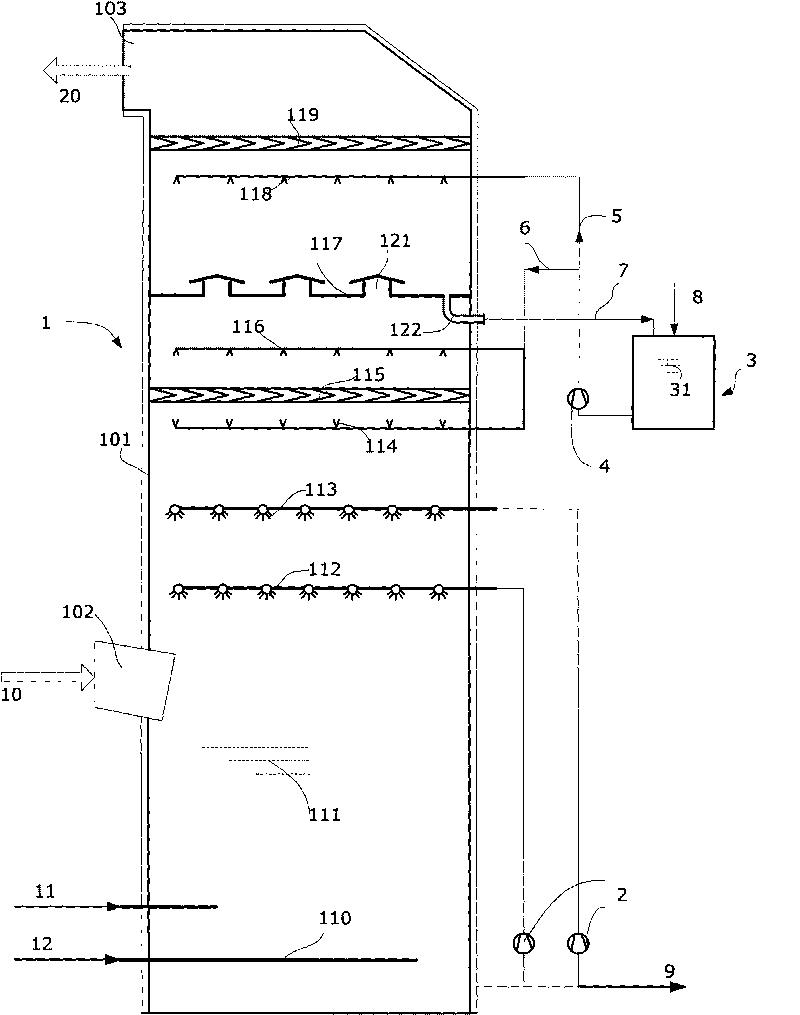

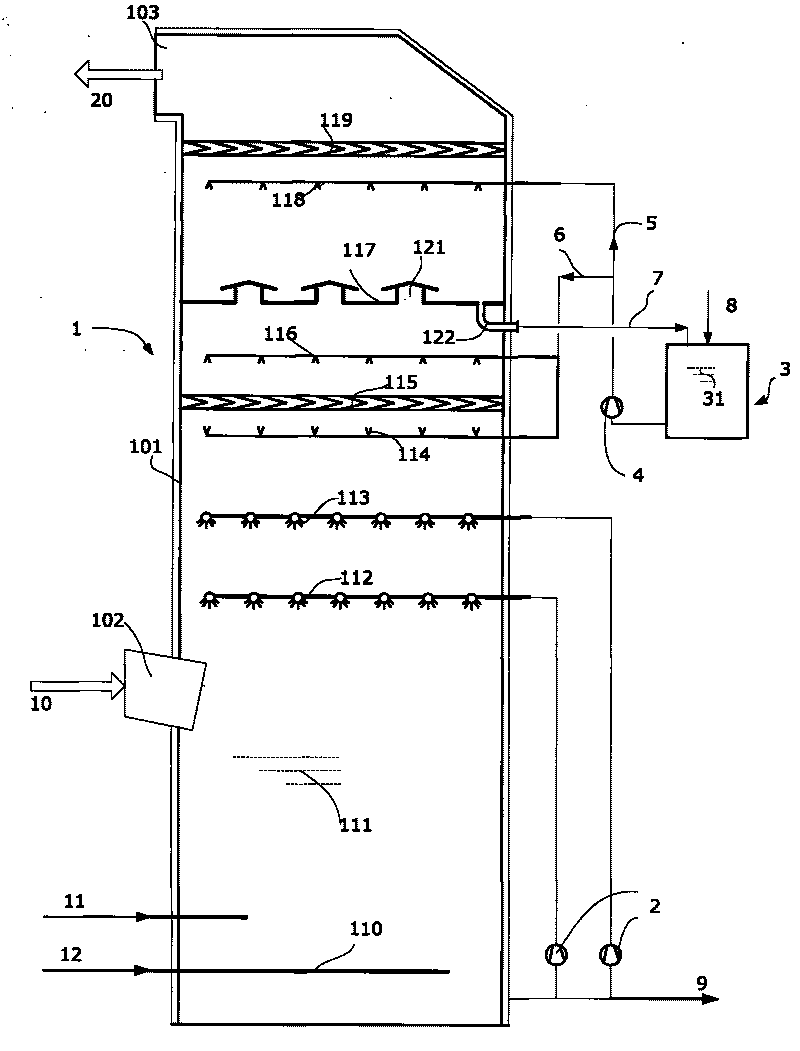

[0025] see figure 1 , an improved exhaust gas purification device, which is used for ammonia exhaust gas purification, that is, flue gas desulfurization process. The raw flue gas 10 containing sulfur dioxide and having a high temperature enters the flue gas desulfurization section of the purification tower 1 through the flue gas inlet 102, and is pumped by the desulfurization circulating pump 2 from the absorption liquid circulation pool at the lower part of the purification tower 2 and transported to the absorption liquid spray Components 112 and 113 are in close contact with the desulfurization absorption liquid 111 sprayed with sulfuric acid crystals, sulfur dioxide becomes ammonium sulfite and dissolves in the absorption liquid, and falls back from the tower to the absorption liquid circulation pool. After being defoamed by the flue gas demister 115, the flue gas passes through the gas-rising cap 121 on the partition 117 and enters the flue gas water washing section to was...

Embodiment 2

[0031] see figure 1 , an improved exhaust gas purification device, which is used in the process of calcium exhaust gas purification, that is, flue gas desulfurization. The raw material 11 is limestone, specifically a mixed slurry of limestone and water, and the average particle size of the limestone is below 100 microns; the desulfurization absorption liquid 111 is a slurry containing calcium sulfate, that is, gypsum crystals, and its solid content is 15%; the washing liquid 31 is a slurry containing A mixed aqueous solution of a very small amount of gypsum solids, with a gypsum content of 0.05%; other operating modes and operating conditions are the same as in Example 1. Through the operation of the above devices, after the desulfurized flue gas is washed by the flue gas water washing section, the purified flue gas does not produce obvious gypsum rain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com