Method for producing hydrogen

A technology of hydrogen and by-products, applied in the direction of electrical components, hydrogen production, battery electrodes, etc., can solve the problems of difficulty in obtaining, not in line with economic benefits, and high cost, and achieve the effect of not causing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

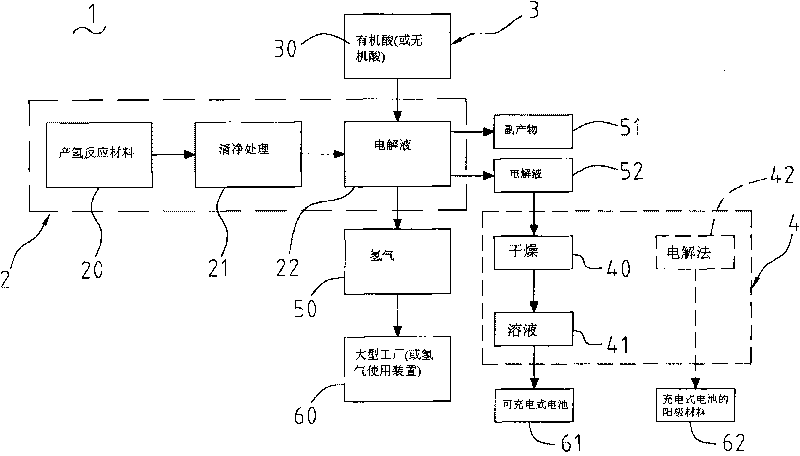

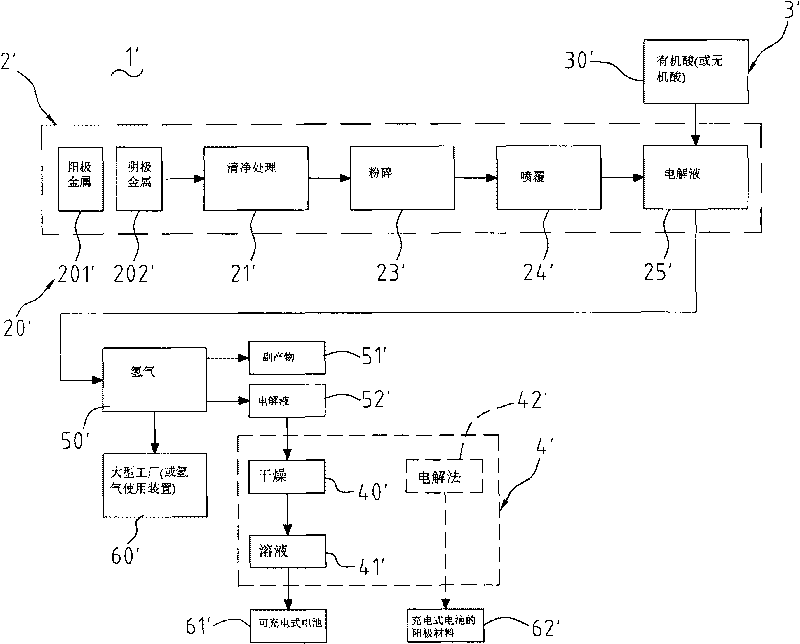

[0023] see figure 1 , which is the flowchart of the first embodiment of the method for generating hydrogen in the present invention, the method 1 for generating hydrogen in the present invention includes: hydrogen production reaction forming step 2 and hydrogen production reaction acceleration step 3, and derivation step 4, wherein the hydrogen production Reaction forming step 2 is to use metal, metal alloy or its waste as hydrogen production reaction material 20, after cleaning treatment 21, contact with electrolyte solution 22 (acidic electrolyte solution or acidic aqueous solution with conductivity can be used) to produce chemical reaction, to obtain Hydrogen 50 and by-products 51 , the generated hydrogen 50 is suitable for large-scale factories (steel plants, incineration plants) or large-scale hydrogen utilization devices (stationary fuel cells) 60 .

[0024] The step 3 of accelerating the hydrogen production reaction is to add organic acid (acetic acid, formic acid, citr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com