Hydrotalcite preparation method

A kind of technology of hydrotalcite and species, applied in the field of preparation of hydrotalcite-like, to achieve the effects of less investment in equipment, high yield and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 28.99g Cu(NO 3 ) 2 ·3H 2 O, 15.01g Al(NO 3 ) 3 9H 2 O, 2.4g NaOH and 6.46g Na 2 CO 3 Stir evenly first, then put it into a 300mL ball mill jar, in a high-energy ball mill (model SM230, Wuxi Xinguang Powder Processing Technology Co., Ltd.), with a speed of 200rpm, ball mill for 5 hours, wash three times, and dry at 80°C to obtain the required Hydrotalcite-like.

Embodiment 2

[0032] 34.5g ZnSO 4 ·7H 2 O, 90.01g Fe(NO 3 ) 3 9H 2 O, 4.8g NaOH and 4.24g Na 2 CO 3 Stir evenly first, then put it into a 300mL ball mill jar, in a high-energy ball mill (model SM230, Wuxi Xinguang Powder Processing Technology Co., Ltd.), with a speed of 50rpm, ball mill for 4 hours, wash three times, and dry at 80°C to obtain the required of hydrotalcites.

Embodiment 3

[0034] 34.5g ZnSO 4 ·7H 2 O, 15.01g Al(NO 3 ) 3 9H 2 O, 2.4g NaOH and 5.35g Na 2 CO 3 Stir evenly first, then put it into a 300mL ball mill jar, and in a high-energy ball mill (model SM230, Wuxi Xinguang Powder Processing Technology Co., Ltd.) at a speed of 300rpm, ball mill for 3 hours, wash three times, and dry at 80°C to obtain the required of hydrotalcites.

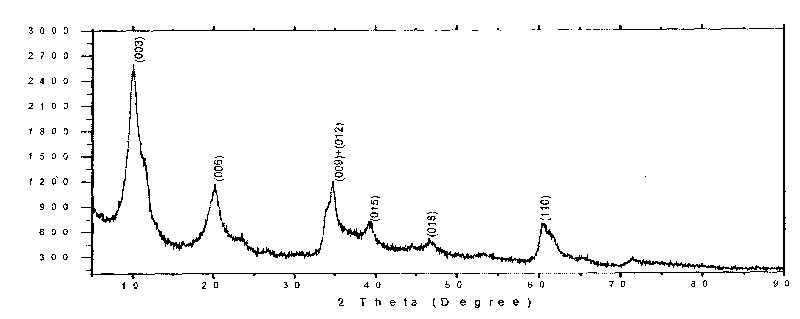

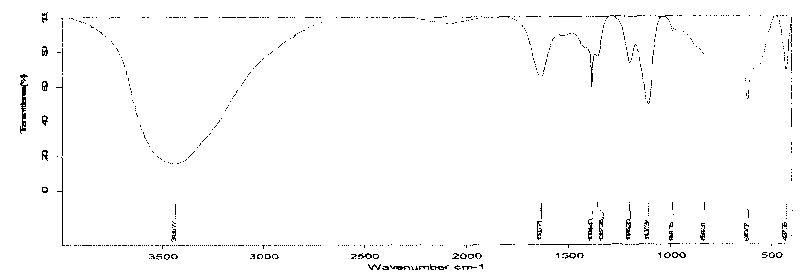

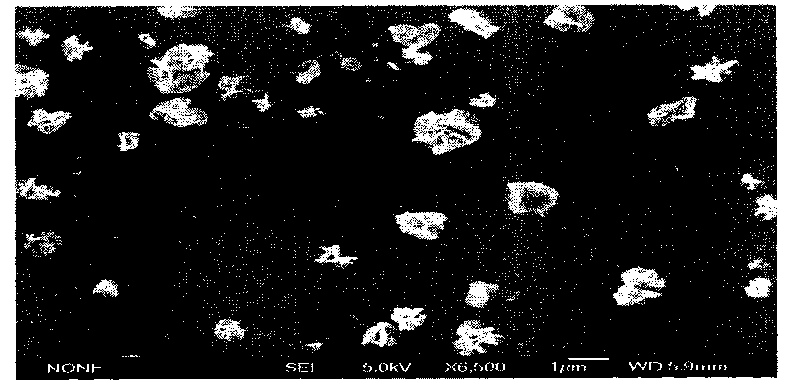

[0035] The XRD, infrared spectrogram and SEM figure of this product are respectively as follows Figure 1-3 shown by figure 1 It can be seen that there are three diffraction peaks (d 003 ) 0.812nm and two advanced reflective 0.437nm (d 006 ), 0.259nm (d 009), indicating that the crystallinity is very good and the crystal phase is single. Layer spacing 0.812nm, d 110 =0.153nm, which is the unit cell parameter a. Depend on figure 2 It can be seen from the infrared spectrum that 3435.77cm -1 It is the OH (laminate) vibration absorption front, 1384.40cm -1 for CO 3 -2 The (interlayer) vibration absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com