Fast thickening vinyl ester resin as well as preparation method and application thereof

A vinyl ester resin and epoxy vinyl ester technology, which is applied in the field of organic polymer synthesis, can solve the problems of turbid resin color, lower product surface quality, and affect product appearance, and achieve transparent resin and thickening speed Excellent effect of increasing speed and thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

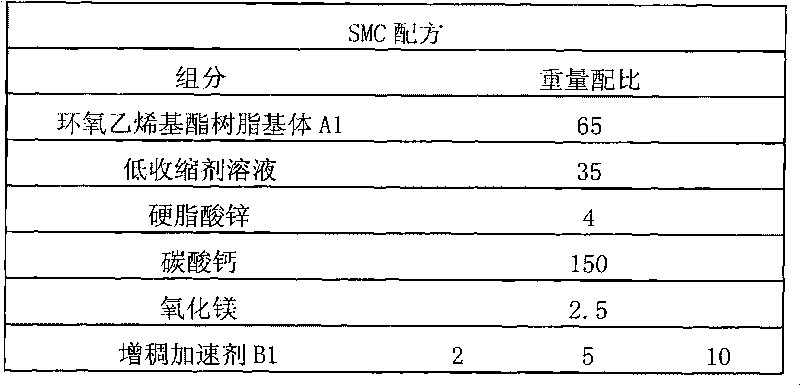

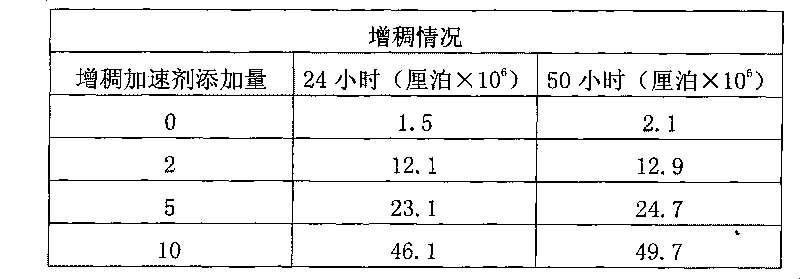

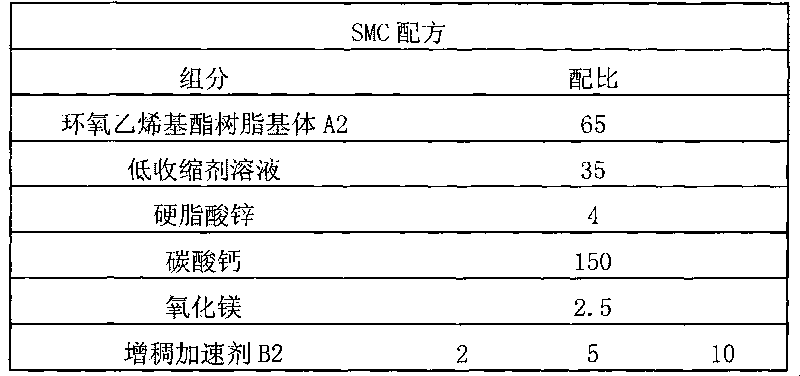

[0048] A kind of fast thickening epoxy vinyl ester resin, is made up of vinyl ester resin matrix and thickening accelerator, and the weight ratio of described thickening accelerator and epoxy vinyl ester resin matrix is 0.03~0.2: 1, in,

[0049] The epoxy vinyl ester resin matrix A comprises the following components in parts by mass:

[0050] Example components (parts by weight) 1 2 3

[0051] Bisphenol A type epoxy resin 1000 1000 1000

[0052] Unsaturated monocarboxylic acid 180 107.5 150

[0053] Maleic anhydride 24 30 35

[0054] Catalyst 2.5 1.25 3

[0055] Inhibitor 0.01 0.13 0.2

[0056] Cross-linking monomer 2150 937.5 2500

[0057] Synthesis of epoxy vinyl ester resin matrix A:

[0058] In the reactor, drop into bisphenol A type epoxy resin (E20), methacrylic acid, N,N-dimethylbenzylamine and hydroquinone according to the above formula, stir under the condition of feeding nitrogen, and gradually heat up to 110°C, keep warm for 5-6 hours, measure the acid val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com