Rubber particle composite and preparing method thereof

A technology of rubber particles and compositions, applied in mechanical equipment, springs made of plastic materials, tire parts, etc., can solve the problems of complicated production process, unable to completely replace natural rubber, and the application scope needs to be expanded, and achieve subsequent applications. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

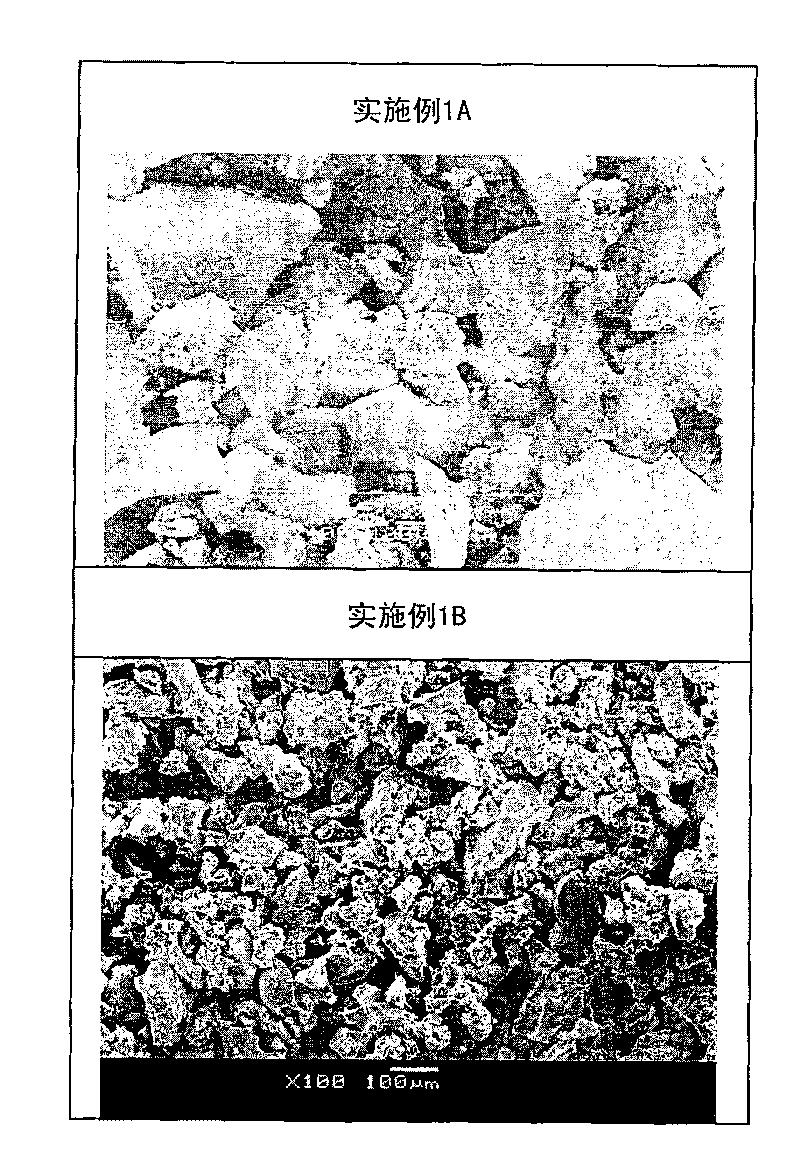

[0037] [Example 1] Preparation of rubber particle composition

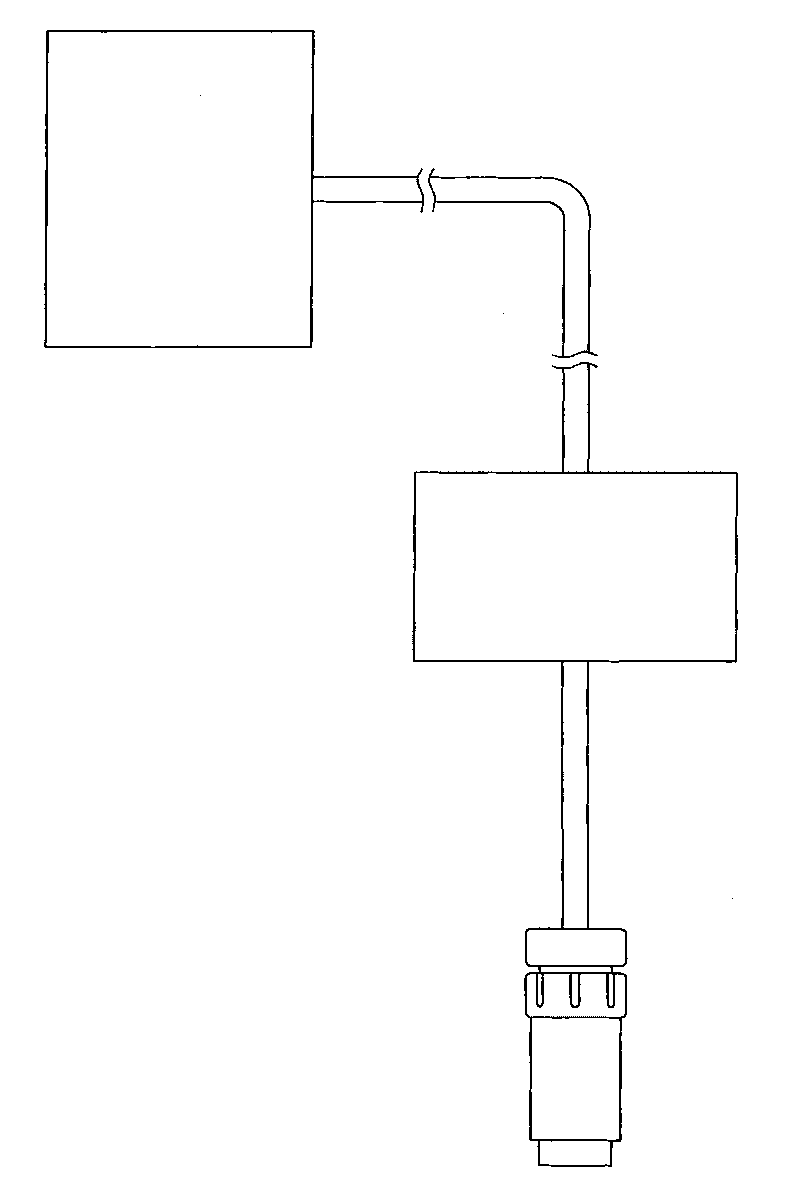

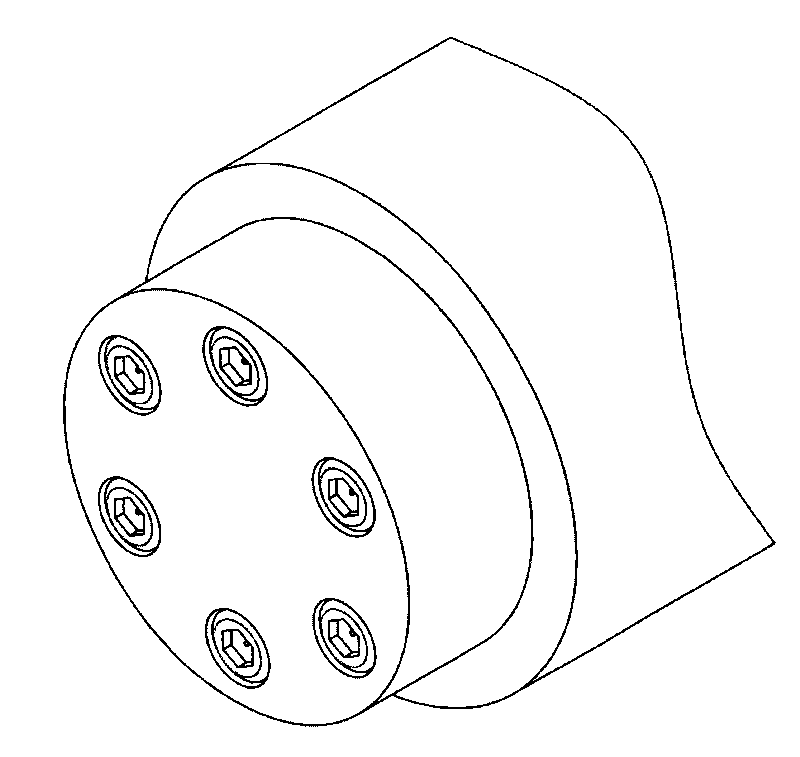

[0038] use figure 1 The high-speed jet fluid produced by the high-pressure jet fluid device (developed and assembled by the applicant of the present invention) impacts the waste tire waste (manufactured by Japan Dunlop Company, the model is SP350, the specification is 12R225, Steel Radial Tubeless, and the appearance shape is flake) , and control the Reynolds number of the high-speed jet fluid to be about 500,000, and the total output kinetic energy is 61×10 3 About kJ, after tens of seconds, the rubber particle composition can be obtained.

[0039] Make the rubber particle composition pass through the sieves of the following three sieve diameters to classify the particle size range: (i) 0.075~0.038mm, (ii) 0.15~0.075mm and (iii) 0.425~0.15mm, and finally obtain Compositions of rubber particles in three different particle size ranges:

[0040] Example number

classification group

Particle size r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com