Molybdenum trioxide microsphere flame-retardant smoke-suppressing polypropylene composite material and preparation method thereof

A molybdenum trioxide and composite material technology, which is applied in the field of polymer materials, can solve the problems of low mechanical properties of polypropylene composite materials, large particle size of molybdenum trioxide microspheres, and poor smoke suppression, so as to increase the difficulty of overflow and ease of use. Procurement, small effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

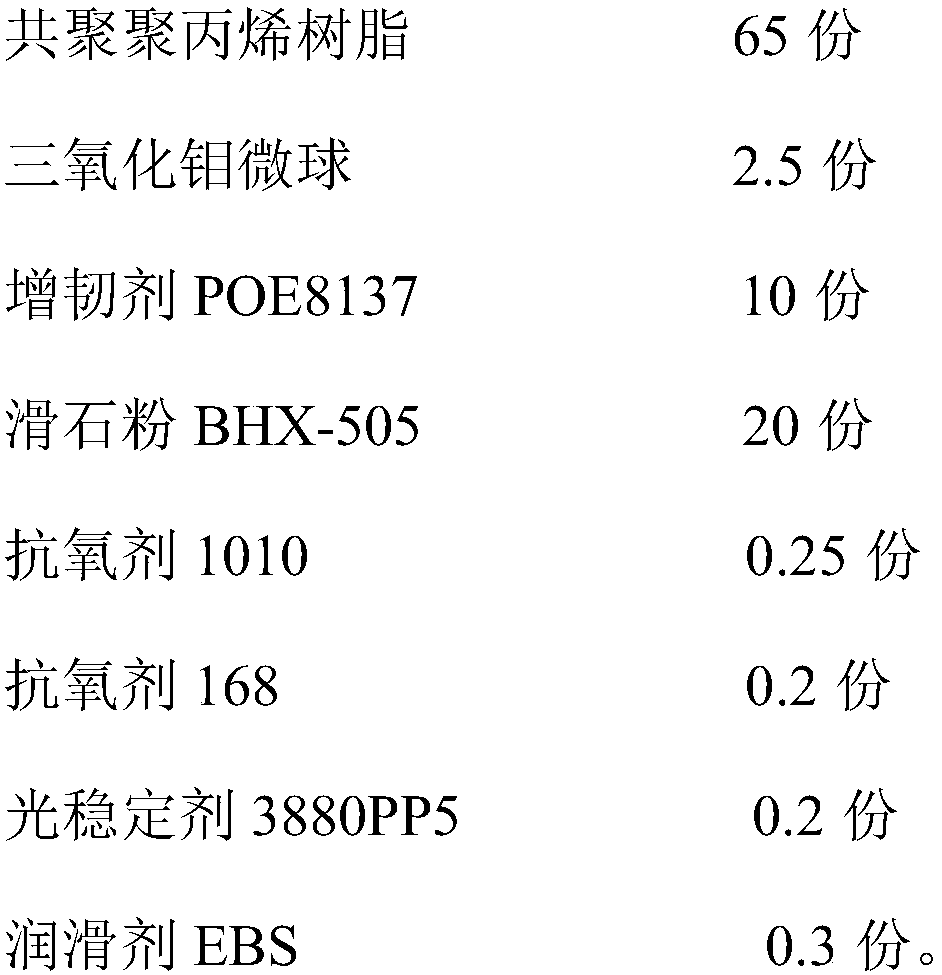

[0026] In this embodiment, the molybdenum oxide microsphere flame-retardant and smoke-suppressing polypropylene composite material is made of the following raw materials in parts by weight:

[0027]

[0028] Concrete preparation method comprises the following steps:

[0029] S1. Weigh 0.005mol of ammonium heptamolybdate and dissolve it in deionized water, stir and dissolve to obtain a saturated solution of ammonium heptamolybdate, adjust the acidity coefficient of the solution to 6 with the configured 2.0mol / L nitric acid solution, and place In an autoclave, use absolute ethanol as a solvent, stir and dissolve completely, treat in an oven at 180°C for 6 hours, filter with suction, wash with water and ethanol in sequence, and dry in a vacuum oven to obtain micromolybdenum trioxide ball;

[0030] S2, 65 parts of copolymerized polypropylene resin, 10 parts of toughening agent POE8137, 20 parts of talcum powder BHX-505, 0.25 parts of antioxidant 1010, 0.2 parts of antioxidant ...

Embodiment 2

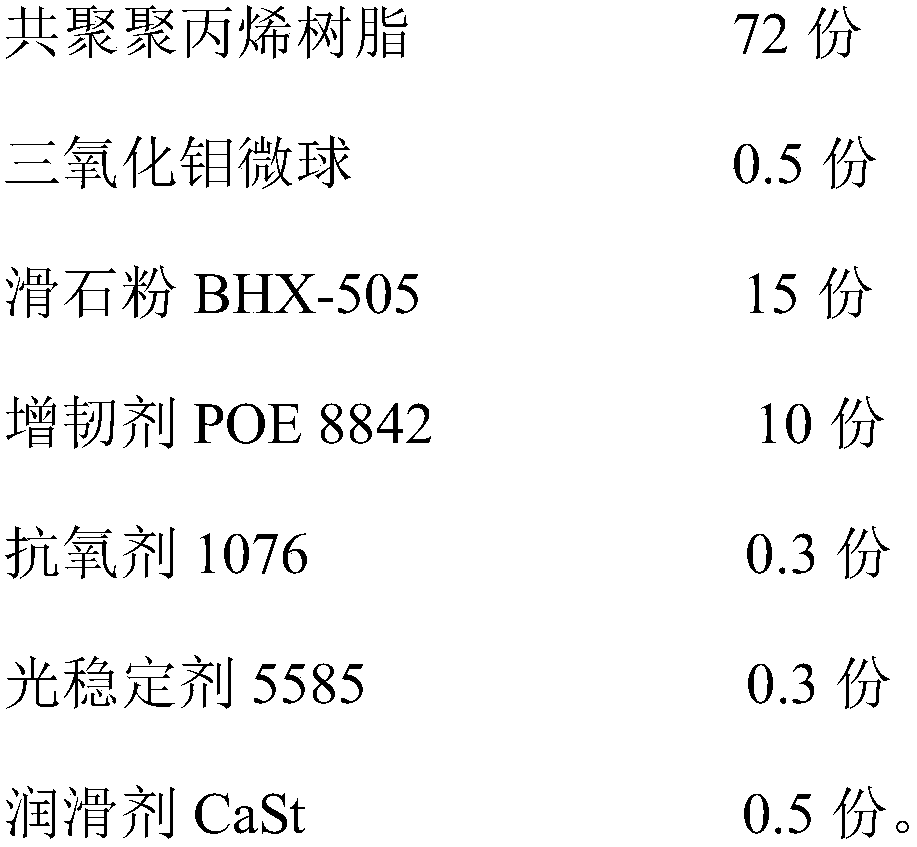

[0033] In this embodiment, the molybdenum oxide microsphere flame-retardant and smoke-suppressing polypropylene composite material is made of the following raw materials in parts by weight:

[0034]

[0035] Concrete preparation method comprises the following steps:

[0036] S1. Weigh 0.008mol of ammonium heptamolybdate and dissolve it in deionized water, stir and dissolve to obtain a saturated solution of ammonium heptamolybdate, adjust the acidity coefficient of the solution to 7 with the configured 2.0mol / L nitric acid solution, and place In an autoclave, use absolute ethanol as a solvent, stir and dissolve completely, treat in an oven at 180°C for 6 hours, filter with suction, wash with water and ethanol in sequence, and dry in a vacuum oven to obtain micromolybdenum trioxide ball;

[0037] S2. Add 72 parts of copolymerized polypropylene resin, 10 parts of toughening agent POE8842, 15 parts of talcum powder BHX-505, 0.3 parts of antioxidant 1076, 0.3 parts of light sta...

Embodiment 3

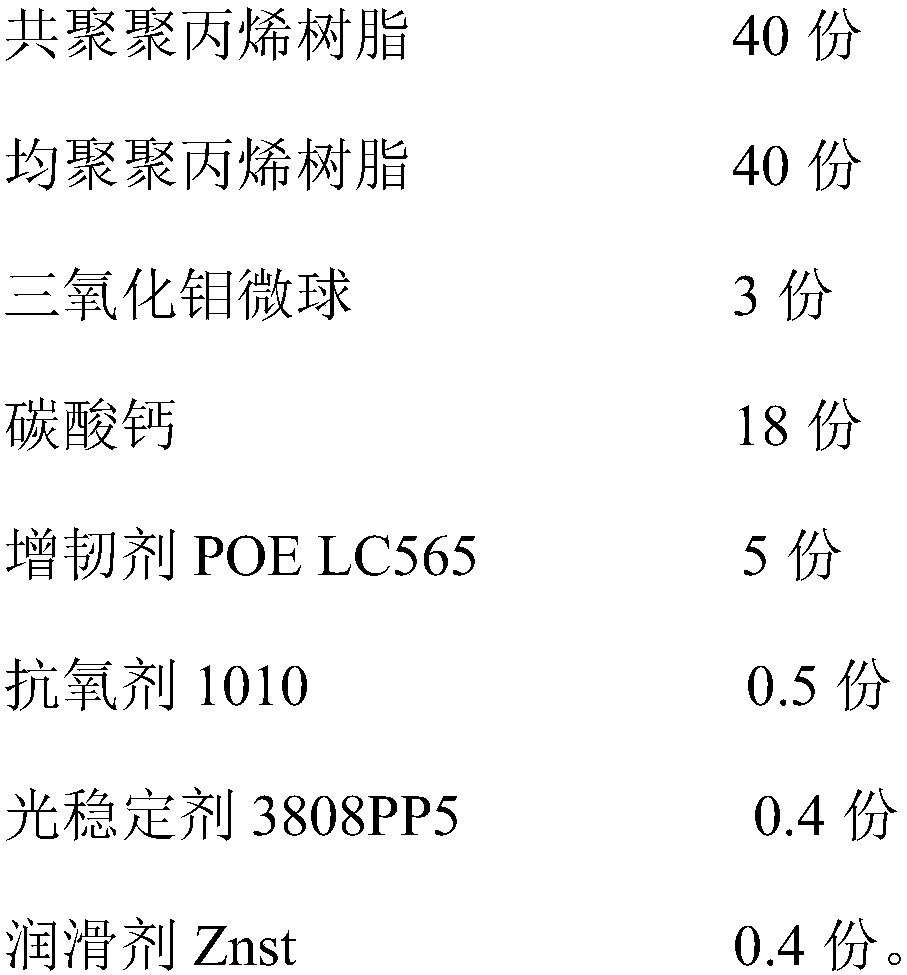

[0040] In this embodiment, the molybdenum oxide microsphere flame-retardant and smoke-suppressing polypropylene composite material is made of the following raw materials in parts by weight:

[0041]

[0042] Concrete preparation method comprises the following steps:

[0043] S1. Weigh 0.006mol of ammonium heptamolybdate and dissolve it in deionized water, stir and dissolve to obtain a saturated solution of ammonium heptamolybdate, adjust the acidity coefficient of the solution to 8 with the configured 2.0mol / L nitric acid solution, and place In an autoclave, use absolute ethanol as a solvent, stir, completely dissolve, treat in an oven at 180°C for 6 hours, filter with suction, wash with water and ethanol in sequence, and dry in a vacuum oven to obtain micromolybdenum trioxide ball;

[0044] S2, 40 parts of copolymerized polypropylene resin, 40 parts of homopolypropylene resin, 5 parts of toughening agent POELC565, 18 parts of calcium carbonate, 0.5 part of antioxidant 1010,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com