Copper and aluminum wire drawing oil and preparation method and use method thereof

A wire drawing oil, copper and aluminum technology, applied in the petroleum industry, additives, lubricating compositions and other directions, can solve the problems of lubricating oil not easy to biodegrade, difficult to achieve lubricating effect, poor environmental friendly benefits, etc., to solve the problem of oil-water emulsification, ultraviolet Excellent storage stability and the effect of ensuring the safety of the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, copper-aluminum drawing oil raw material and weight percent are as follows:

[0022] components

Name / Characteristic Parameters

Content (%)

Naphthenic base oil: kinematic viscosity at 100°C is

15.0mm 2 / s, the distillation range is 340~500℃

72.0%

[0023] primary emulsifier

Sodium naphthenate (molecular weight 340)

16.0%

co-emulsifier

PEG-200

10.0%

T911

0.5%

Rust inhibitor

0.2%

preservatives

3-iodo-2-propynylbutylcarbamate

0.2%

antiwear agent

Sulfurized isobutylene

1.1%

[0024]The specific preparation method is: first add the base oil into the reactor, stir and heat to 50°C, then add the main emulsifier and auxiliary emulsifier, and stir for 45min at a temperature of 60°C; then add defoamer, anti-rust Agents, preservatives, anti-oxidants and anti-wear agents, s...

Embodiment 2

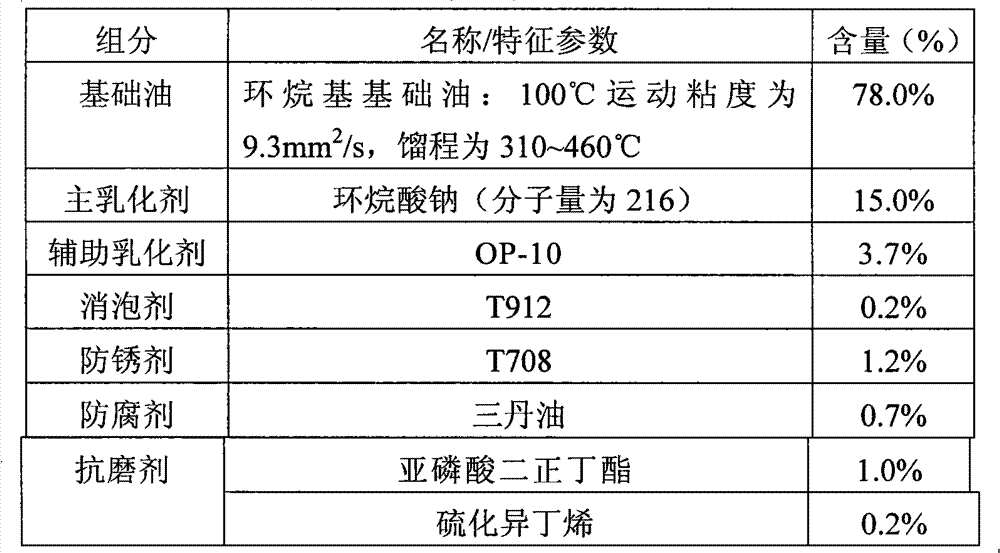

[0027] Embodiment 2, copper-aluminum drawing oil raw material and weight percent are as follows:

[0028]

[0029] The specific preparation method is as follows: first add the base oil into the reactor, stir and heat to 55°C, then add the main emulsifier and auxiliary emulsifier, and stir for 30 minutes at a temperature of 50°C; then add the defoamer, antirust Add additives, preservatives, anti-oxidants and anti-wear agents into the reactor, stir at 50°C until completely dissolved, stop heating and wait for cooling to become the finished product.

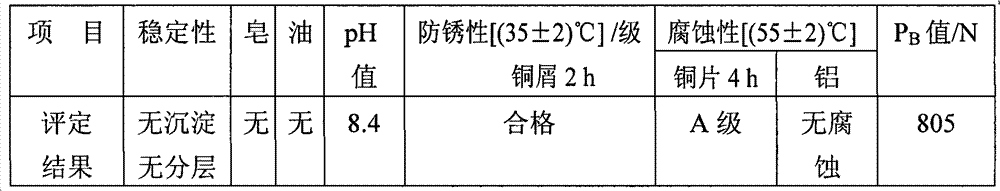

[0030] The above-mentioned finished wire drawing oil is configured into the performance evaluation of 5% wire drawing oil-water emulsion as follows:

[0031]

Embodiment 3

[0032] Embodiment 3, copper-aluminum drawing oil raw material and weight percent are as follows:

[0033]

[0034] The specific preparation method is as follows: first add the base oil into the reactor, stir and heat to 60°C, then add the main emulsifier and auxiliary emulsifier, and stir for 50 minutes at a temperature of 55°C; then add the defoamer, antirust Add additives, preservatives, anti-oxidants and anti-wear agents into the reactor, stir at 55°C until completely dissolved, stop heating and wait for cooling to become the finished product.

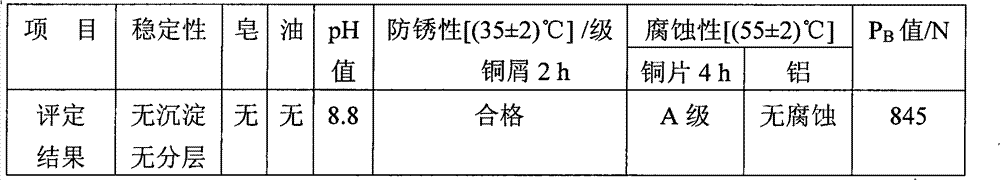

[0035] The performance evaluation after the above-mentioned finished wire drawing oil is configured into 3% wire drawing oil-water emulsion is as follows:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com