Electron beam evaporation plant

A technology of electron beam evaporation and copper crucible, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve problems such as aluminum splashing accidents, achieve small heat conduction losses, avoid aluminum splashing accidents, and melt uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

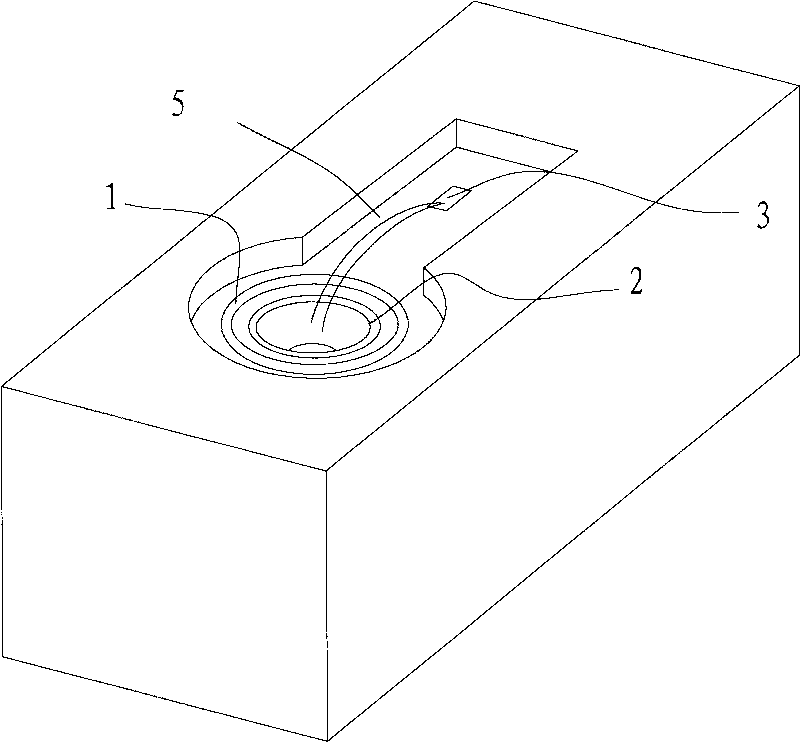

[0027] figure 1 It is a schematic structural diagram of the electron beam evaporation device of the present invention.

[0028] Such as figure 1 As shown, the electron beam evaporation device of the present invention includes a copper crucible 1, an electron gun, a cooling water pipe, a magnet, a deflection coil (not shown) and the like. The electron gun is used to emit an electron beam that heats the aluminum source to evaporate the aluminum source. The electron gun is arranged in the evaporation device and emits the electron beam 5 to the crucible through the electron beam outlet 3. The magnet and the deflection coil are used to control the direction and deflection of the electron beam 5 angle, and the cooling water pipe is used for cooling the magnet and deflection coil.

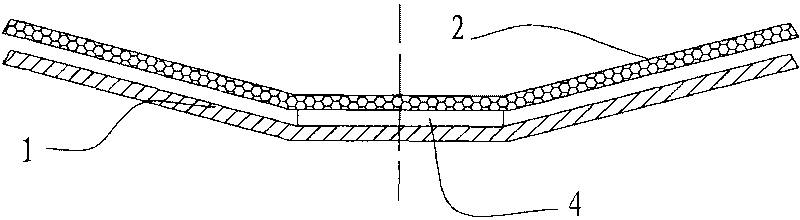

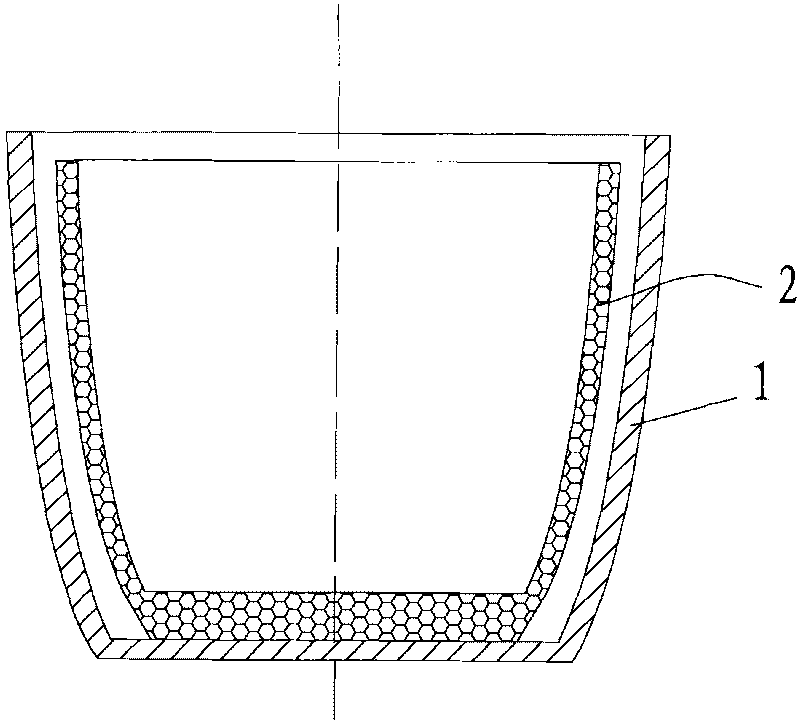

[0029] A crucible lining 2 made of heat-resistant material is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com