Auxiliary quick construction method of temporary light rail in coke furnace building thermal state project

A construction method and coke oven technology, which are used in coke oven bricklaying operations, construction, building construction, etc., can solve problems such as construction period impact, worker injury, slow construction, etc., so as to shorten construction period, ensure construction quality, and avoid safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

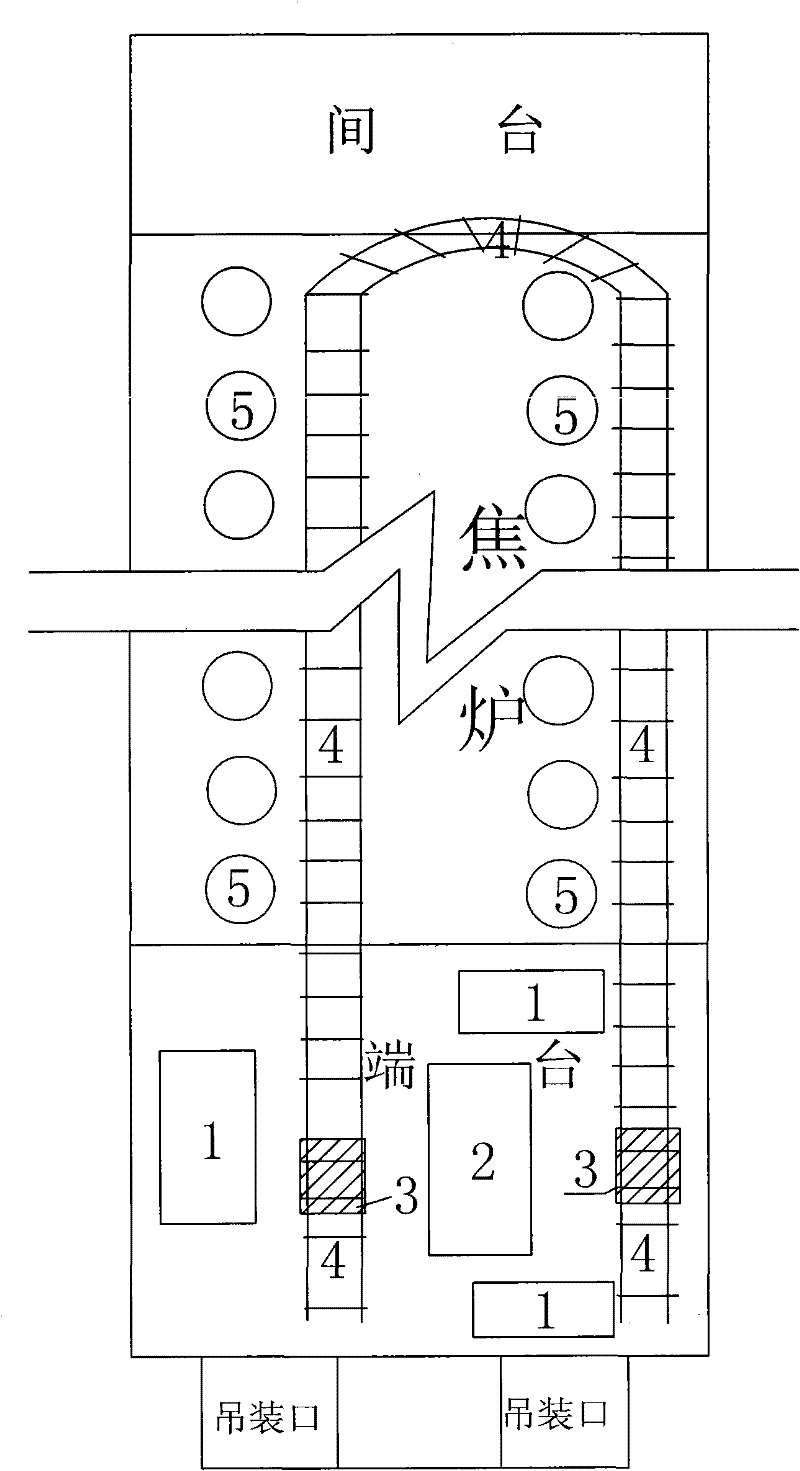

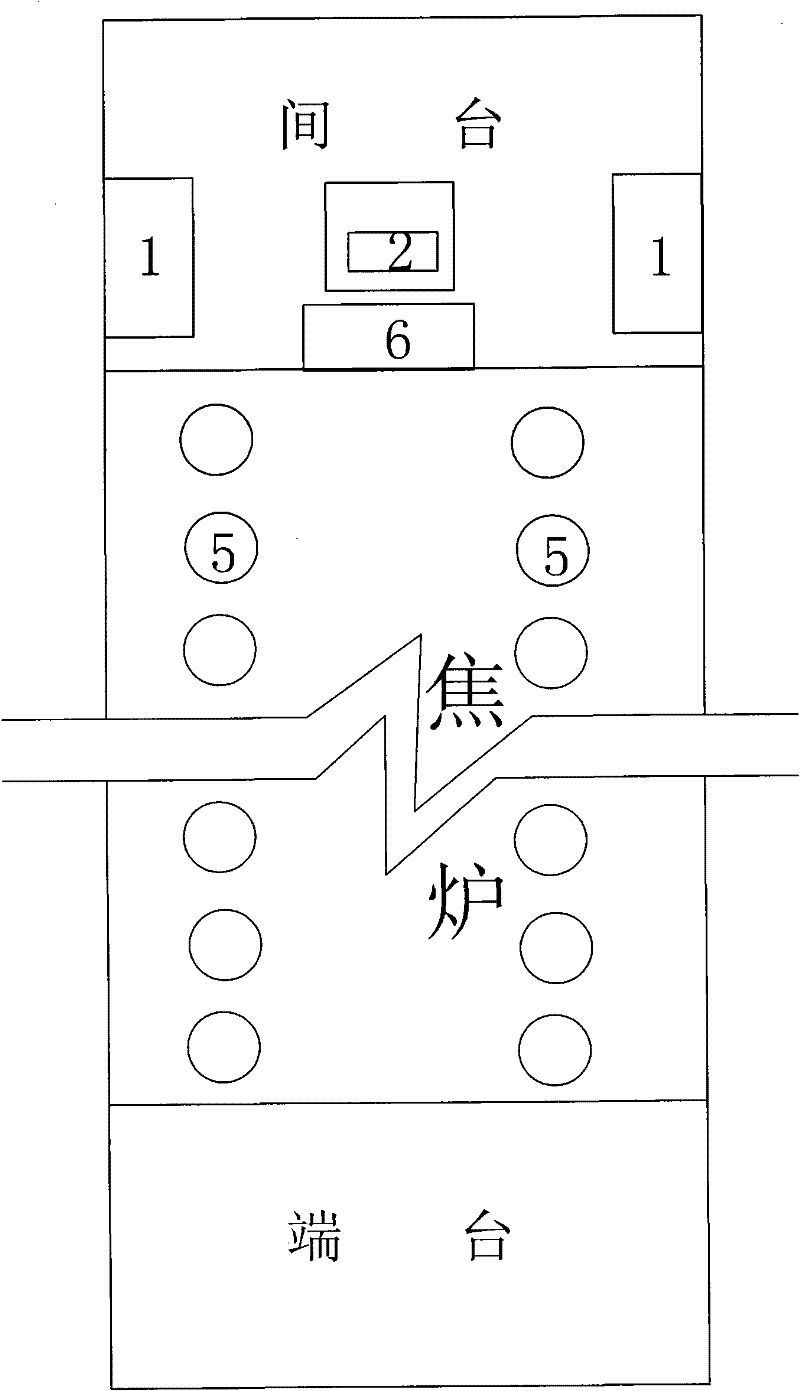

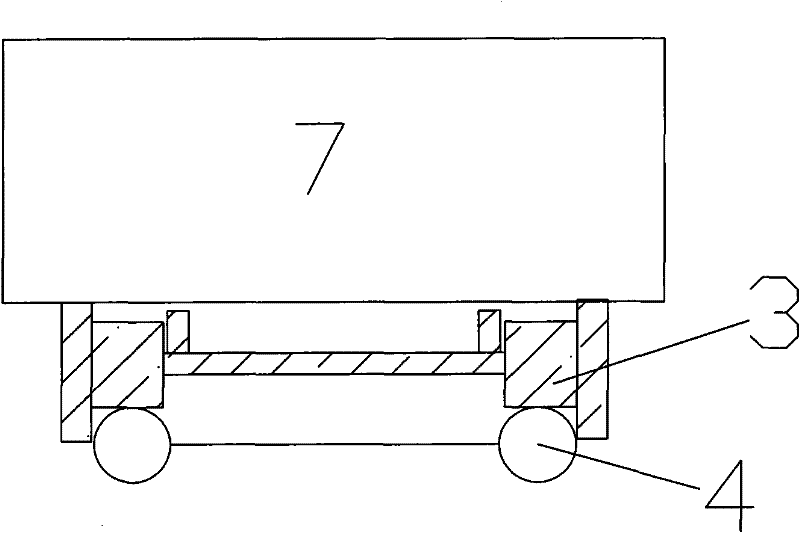

[0024] The temporary light rail assisted rapid construction method for coke oven masonry thermal engineering provided by the present invention is specifically: use common scaffolding steel pipes and flat steel commonly used in engineering to form temporary light rails and lay them on the top surface of the coke oven to facilitate coking. The most important thing in the masonry and grouting construction of hot refractory mud during furnace hot construction is on the top surface of the coke oven, which can conveniently and quickly transport the refractory materials to any place on the top surface of the furnace. see figure 1 , the method includes the following steps:

[0025] 1. Set up mixing station 2:

[0026] Set up the mixing station at the very center of the top surface of this end platform. Mixing station 2 includes: 2 sets of mixers, 1 simple platform built with scaffolding steel pipes and wooden springboards, as the placement point of the mixer, the area of the simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com