High-cost performance system for controlling combustion redundancy of coal-fired heat transfer material heater

A heat carrier furnace and redundant control technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the difficulty of combustion control of coal-fired heat medium furnace, failure of CPU module protection, and difficult to achieve temperature control accuracy, etc. problem, to achieve a good modular structure, good performance, good real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

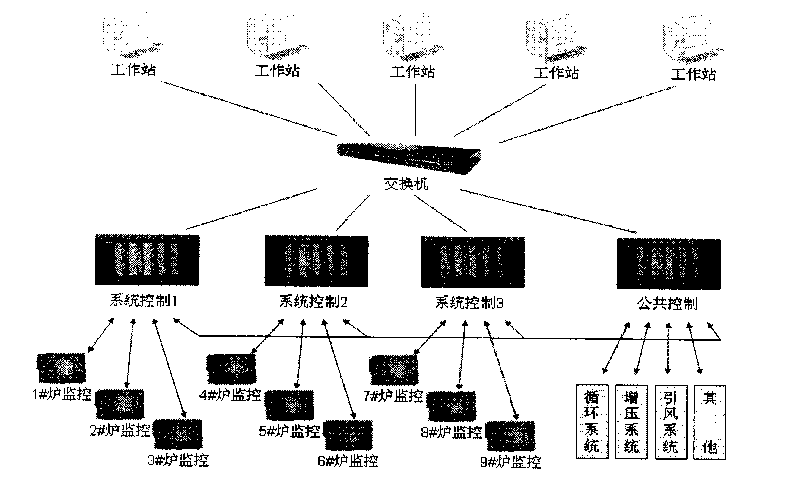

[0026] The following is a block diagram of the DCS control system structure of nine 7 million kcal coal-fired heat medium furnaces (as attached figure 1 shown).

[0027] An automatic heat medium furnace engineering control system of the present invention controls nine coal-fired heat medium furnace systems including three heat supply circulation systems.

[0028] The upper layer consists of four operator stations, one engineer station and Ethernet switches. The operator station and the engineer station are respectively equipped with Advantech PIII industrial computer, ViewSonic 19 o'clock LCD screen, EPSON printer, etc. Under normal circumstances, four operator stations operate and control four subsystems (corresponding to four system control cabinets of C01, C02, C03, and C04), and one engineer station is used for system management. The software and hardwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com