Semiconductor high-voltage terminal structure and production method thereof

A terminal structure and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of slow gradient gradient, cumbersome process, and complex calculation, etc., and achieve downsizing , Improve the effect of process tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

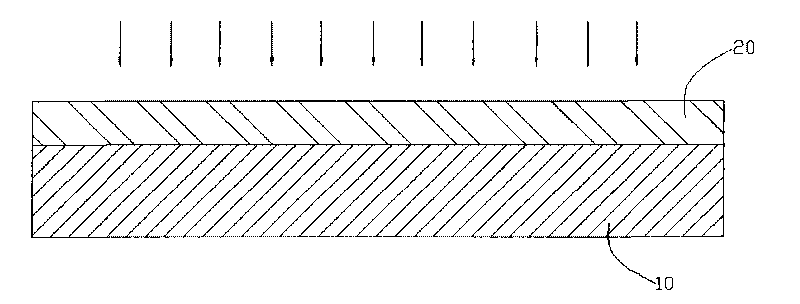

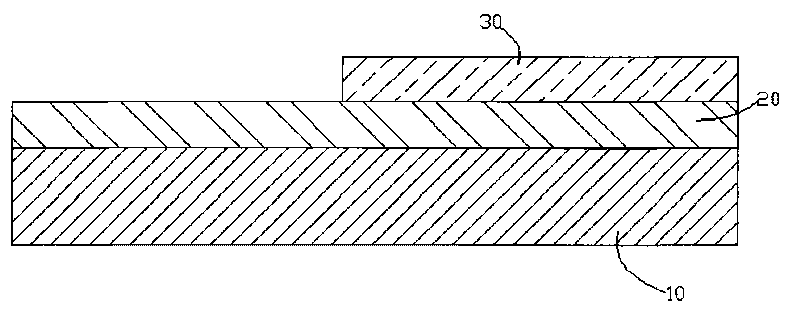

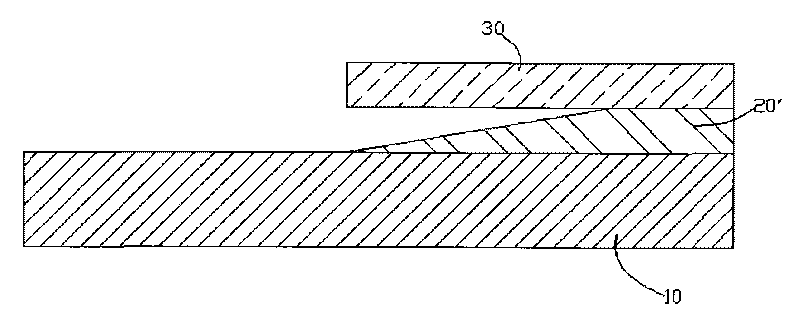

[0024] Please refer to figure 1 , the first step of the manufacturing method of the semiconductor high-voltage terminal structure of the present invention is to form a field oxide layer 20 by thermal growth on the silicon (Si) substrate 10, and the field oxide layer 20 is silicon dioxide (SiO 2 ) layer with a thickness of 1000 nm-1500 nm, in fact, the field oxide layer can also be other silicon compounds, such as silicon oxynitride and the like. By means of ion bombardment, a damaged layer is introduced on the top of the field oxide layer, so that this part of the damaged field oxide layer has a faster corrosion rate; this effect can also be achieved by chemical vapor deposition of a certain thickness of corrosion-prone oxide layer is reached. In this step, in order to corrode the field oxide layer into a slope shape in subsequent steps, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com