Silicon-based thin film solar cell with microcrystalline silicon-germanium thin film as intrinsic layer and preparation method thereof

A technology of microcrystalline silicon germanium and solar cells, applied in the field of solar cells, can solve problems such as uneven structural order, inconsistent structure, and affecting device performance, and achieve the effects of novel structure, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

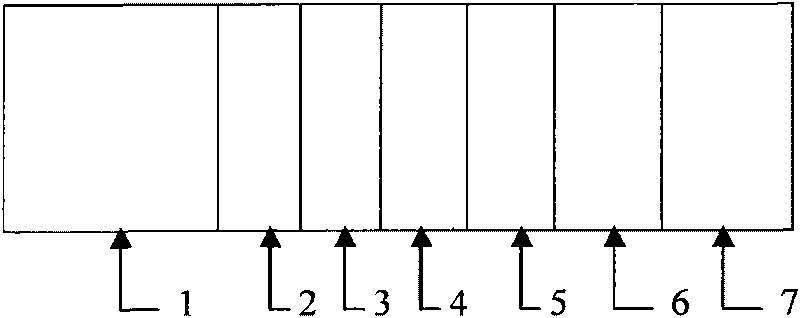

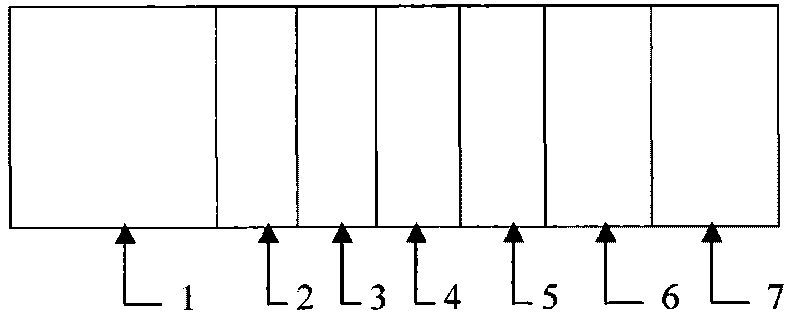

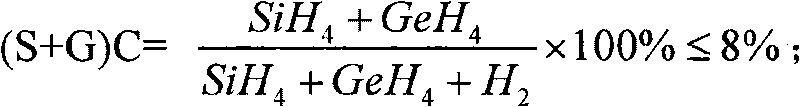

[0021] A silicon-based thin-film solar cell whose intrinsic layer is a microcrystalline silicon-germanium thin film, comprising a transparent substrate 1, a transparent conductive thin film 2, a P-type window layer 3, an intrinsic layer I 4, N + Layer 5, back reflection electrode 6 and metal electrode 7, the back reflection electrode 6 is ZnO, the metal electrode 7 is silver, and the intrinsic layer I4 is a microcrystalline silicon germanium film. In this silicon germanium thin film solar cell, the preparation method of the microcrystalline silicon germanium thin film as intrinsic layer comprises the following steps: 1) the Corning7059 glass substrate that thickness is 1.5mm and is plated with ZnO transparent conductive thin film is placed in vacuum chamber, The background vacuum is higher than 2×10 -4 Pa; 2) Under the condition of feeding reaction gas silane, germane, germanium fluoride and hydrogen into the reaction chamber, deposit microcrystalline silicon germanium film, t...

Embodiment 2

[0023] A silicon-based thin-film solar cell whose intrinsic layer is a microcrystalline silicon-germanium thin film, its structure and materials are basically the same as those in Example 1, except that the metal electrode M7 is aluminum. The preparation method of the microcrystalline silicon germanium thin film as the intrinsic layer is also basically the same as in Example 1, the difference is that the transparent conductive film adopts SnO 2 -ZnO composite transparent conductive film. The microcrystalline silicon-based thin film solar cell prepared by this method has been tested and shown that when the thickness of the intrinsic layer is 750nm, the short-circuit current reaches 23mA / cm 2 , the photoelectric conversion efficiency reaches 6.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com