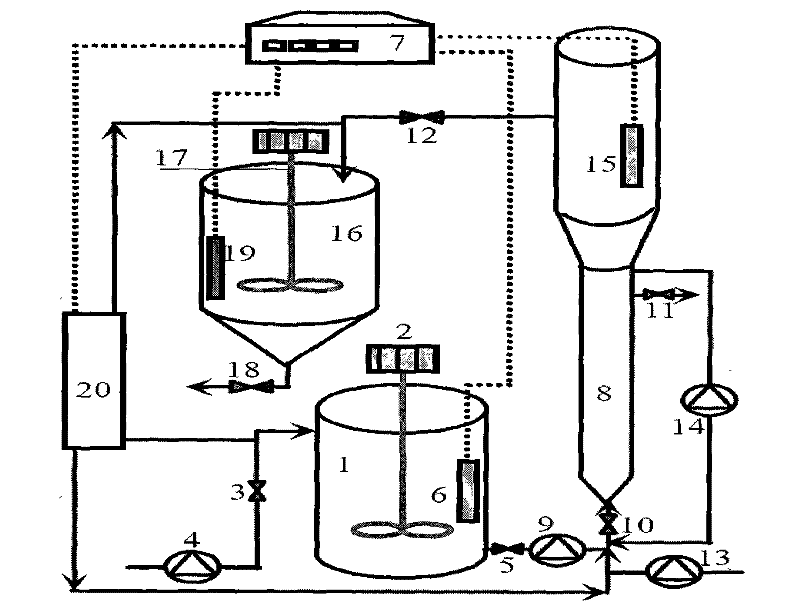

Two grade alkaline hydrolysis and acidification device for processing residual activated sludge

A technology of hydrolytic acidification and residual activity, applied in biological sludge treatment, etc., can solve the problems of sludge treatment difficulties, lack of carbon sources, etc., and achieve the effect of accelerating the hydrolysis rate and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

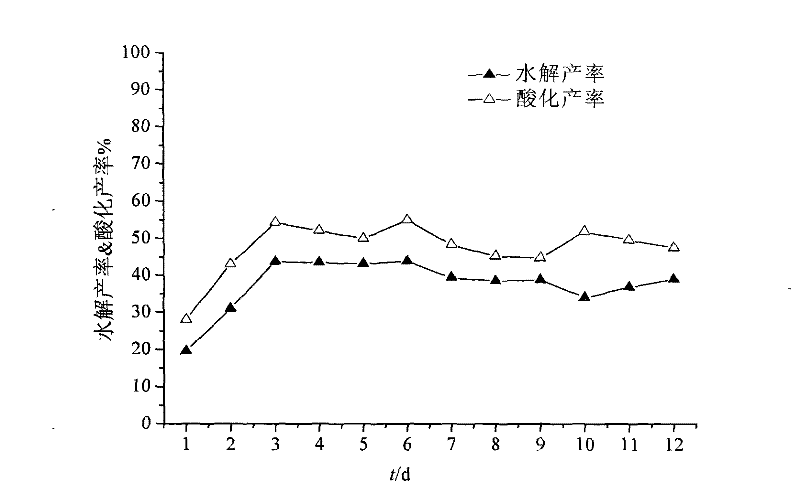

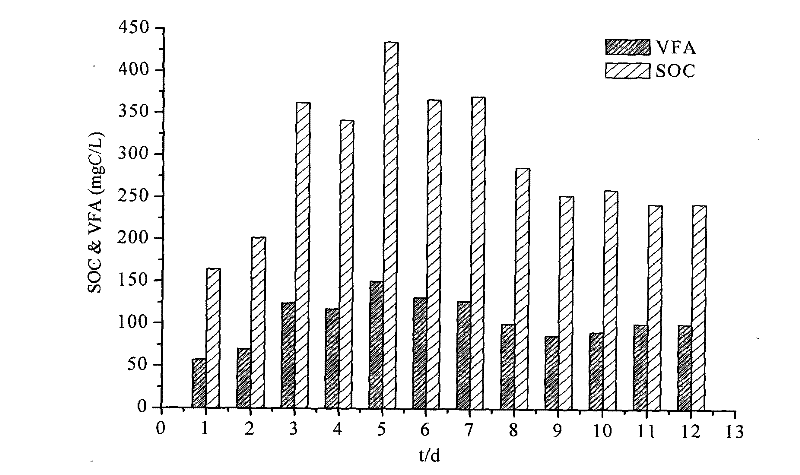

[0033] Implementation example: A / O reactor and oxidation ditch reactor with actual domestic sewage (pH=6.5~7.8, COD=260~350mg / L, TN=60~85mg / L) discharged from a family area of a university as the experimental object A large amount of excess activated sludge is produced, which is mixed and concentrated as sludge for two-stage alkaline hydrolysis acidification treatment device. The effective volume of the entire reaction system is 31L, the MLSS after sludge concentration is 15-20g / L, and the TCOD is 17.6-25.2g / L. Add 2L of concentrated sludge every day to produce 48L of available sludge hydrolysis acidification solution. After the system is stabilized, the two-stage alkaline hydrolysis efficiency of sludge can reach 38.19%, and the acidification efficiency can reach 51.69%, such as figure 2 shown. The concentration of SOC in the effluent of sludge two-stage alkaline hydrolysis and acidification solution is 180-430mgC / L, and the concentration of VFA is 75-150mgC / L. image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com