Method for removing capsaicin during production process of capsicum red pigment

A capsanthin and capsanthin production process technology, applied in the production field of capsaicinoids and capsanthin, can solve the problems of capsanthin loss, difficult ethanol with water, incomplete despicy removal, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

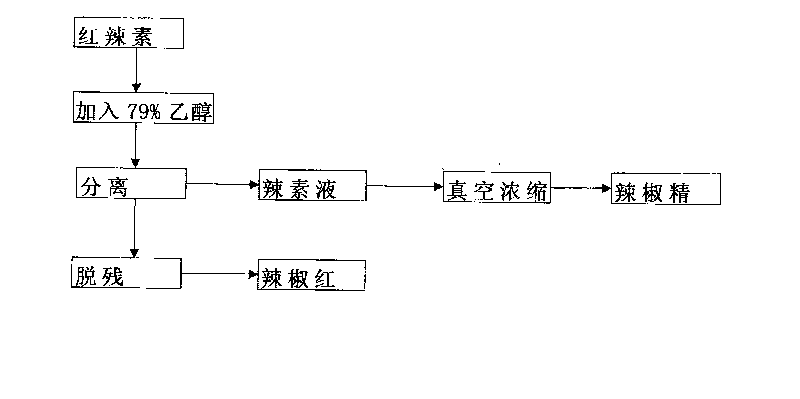

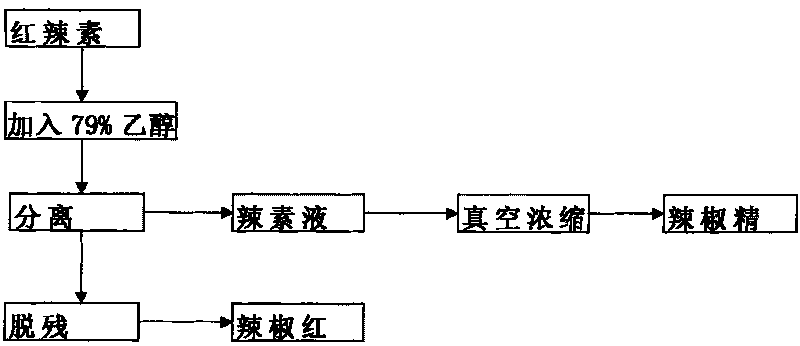

Image

Examples

Embodiment Construction

[0015] A method for removing capsaicin in the production process of capsanthin, the process steps are: ① put a certain amount of red capsaicin, the raw material for producing capsanthin, into a certain capacity equipped with a heating port, a vent port, and an inlet In a double-layer tank-like container with a vacuum and air pressure function, a stirring device, and an external heating jacket, and a certain amount of 79% concentration by volume is added to the tank-like container. Water-containing ethanol, ③Connect the heating port of the tank-shaped container to the hot circulating water pipeline, heat the red capsicum and water-containing ethanol in the tank-shaped container to ≤42 degrees Celsius by means of water bath heating, and stir at a constant speed For a certain period of time, ④ then stop stirring, stand still for a certain period of time, and the capsanthin with lighter specific gravity will float up to realize the separation of capsanthin and capsaicin liquid. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com