Leaching method of magnesium-containing ore

A magnesium ore and leaching technology, applied in the field of hydrometallurgy, can solve the problems of energy consumption, environmental pollution again, high equipment requirements, etc., and achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

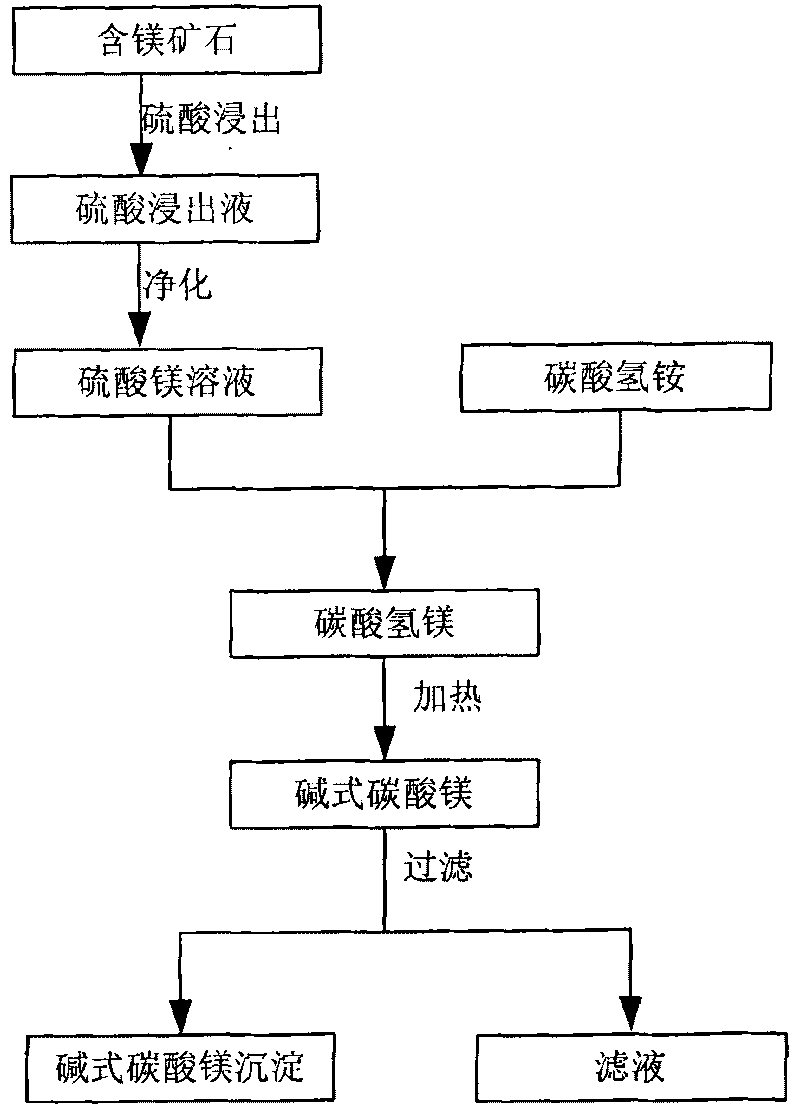

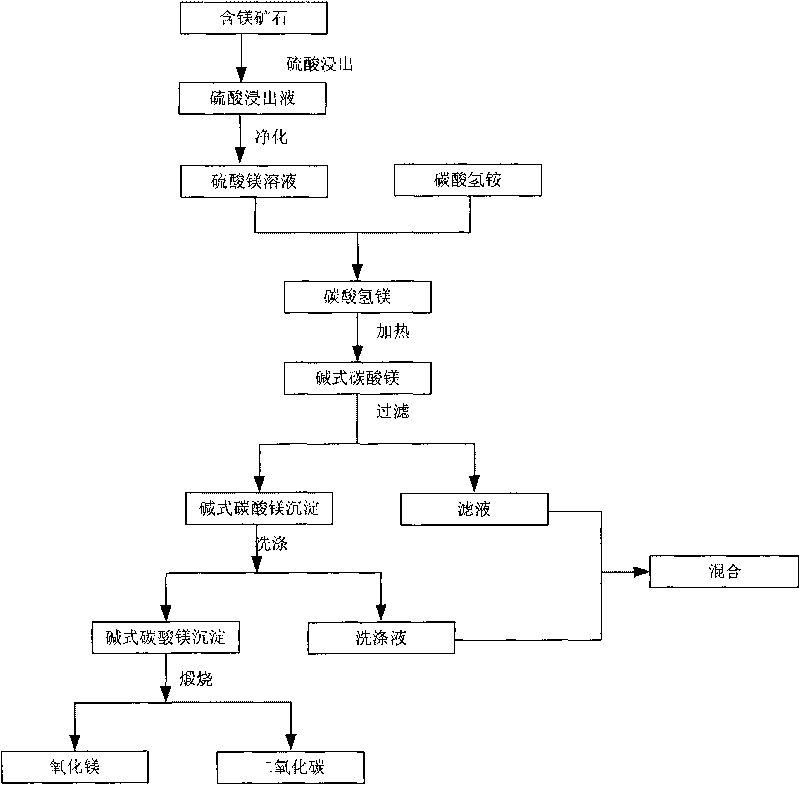

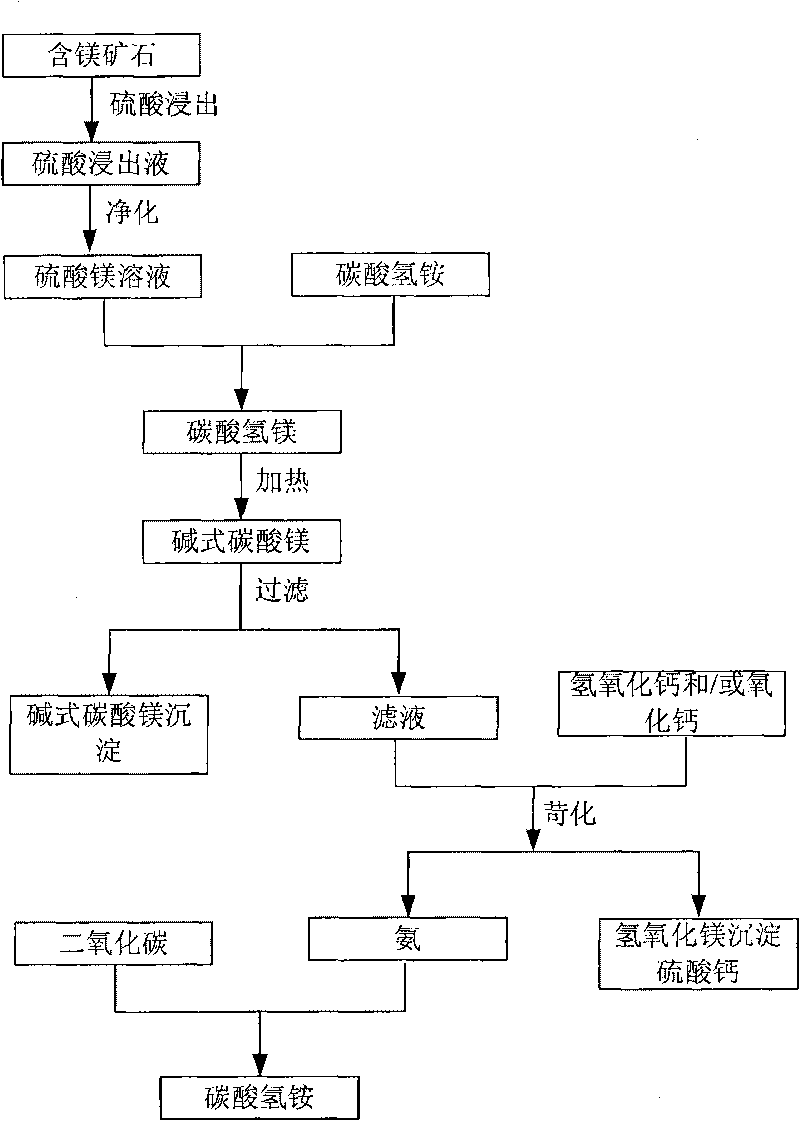

Method used

Image

Examples

example 1

[0061] Table 1 contains magnesium sulfate leaching solution composition list (g / L), wherein the magnesium sulfate solution is obtained after the sulfuric acid leaching solution containing magnesium ore is purified.

[0062] Mg

SO 4 2-

Al

Ni

co

mn

Fe

26-40

103~158

0.023

0.004

0.0016

0.0024

0.002

[0063] Ammonia water: 10-25% concentration ammonia water

[0064] Get the leaching solution 500mL containing magnesium sulfate of table 1

[0065] NH 4 HCO 3 1.0 to 1.2 times the theoretical amount

[0066] How to join: NH 4 HCO 3 The aqueous solution is added to the leaching solution containing magnesium sulfate

[0067] Reaction temperature: 50~40℃

[0068] Reaction time: 0.5 hours

[0069] Pyrolysis temperature: 60℃~95℃

[0070] Pyrolysis time: 0.5 hours

[0071] Yield based on Mg: 70-75%

[0072] Product purity: ≥98%

example 2

[0074] Get the leaching solution 500mL containing magnesium sulfate of table 1

[0075] solid NH 4 HCO 3 1.0 to 1.2 times the theoretical amount

[0076] Addition method: solid NH 4 HCO 3 The aqueous solution is added to the leach solution containing magnesium sulfate

[0077] Reaction temperature: room temperature

[0078] Reaction time: 0.5 hours

[0079] Pyrolysis temperature: 60℃~95℃

[0080] Pyrolysis time: 0.5 hours

[0081] Filtration time: 0.5 minutes to 5 minutes

[0082] Yield based on Mg: 70-75%

[0083] Product purity: ≥98%

example 3

[0085] Get the leaching solution 500mL containing magnesium sulfate of table 1

[0086] NH 4 HCO 3 1.1 times the theoretical amount

[0087] Ammonia water: 25% ammonia water 5mL

[0088] How to join: NH 4 HCO 3 And ammonia water is added to the leaching solution containing magnesium sulfate

[0089] Reaction time: 0.5 hours

[0090] Pyrolysis temperature: 60℃~95℃

[0091] Pyrolysis time: 0.5 hours

[0092] Yield based on Mg: 80-85%

[0093] Product purity: ≥98%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pyrolysis temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com