Method and device for thermal physical property test of high-temperature phase-change energy storage material

A technology of energy storage materials and high-temperature phase change, applied in the direction of material thermal development, etc., can solve the problems of increasing the outlet temperature fluctuation range, affecting the life of the container, and excessive temperature, so as to improve testing efficiency, low raw material cost, and low raw material cost. Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

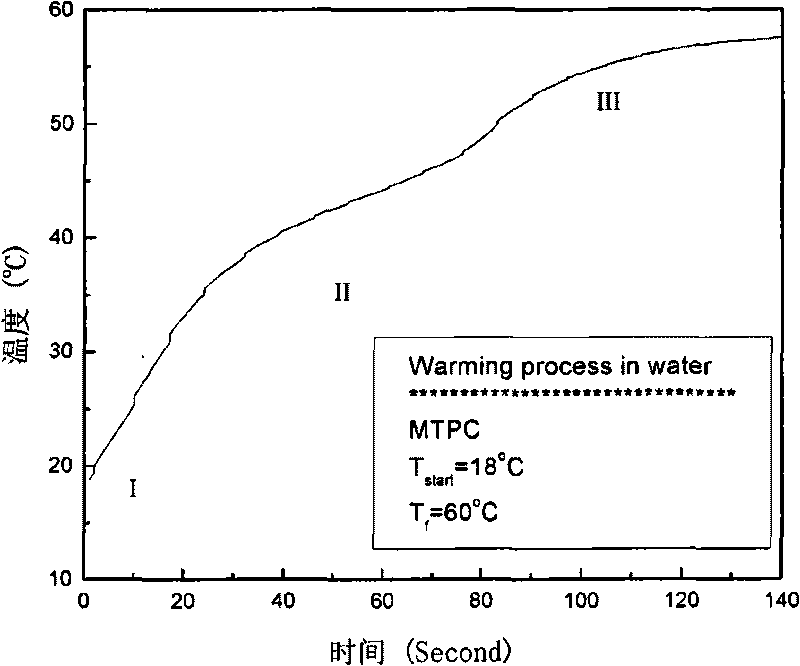

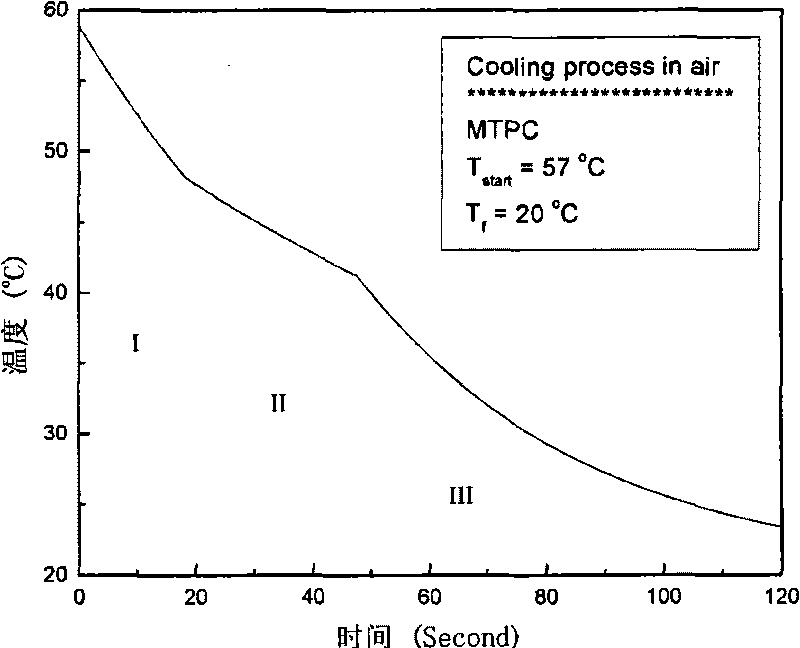

[0071] Example 1: LiNO 3 / NaNO 3 Thermophysical property test of high temperature phase change energy storage materials

[0072] According to the mass ratio of 5.5:4.5, weigh 27.50g LiNO with an electronic scale 3 and 22.50g NaNO 3 , mixed and ground into a 50ml nickel crucible. Fix the nickel crucible in an iron box and place it in a resistance furnace at 220°C until the inorganic salt mixture is completely melted, take out the iron box, bury all the thermocouple probes in the molten salt, and place them in the middle of the crucible without touching the bottom of the crucible. Allow it to cool naturally, and use it as a standard sample. After the molten salt is solidified, the thermocouple is also fixed in it, and the nickel crucible with the thermocouple is fixed on the iron box support.

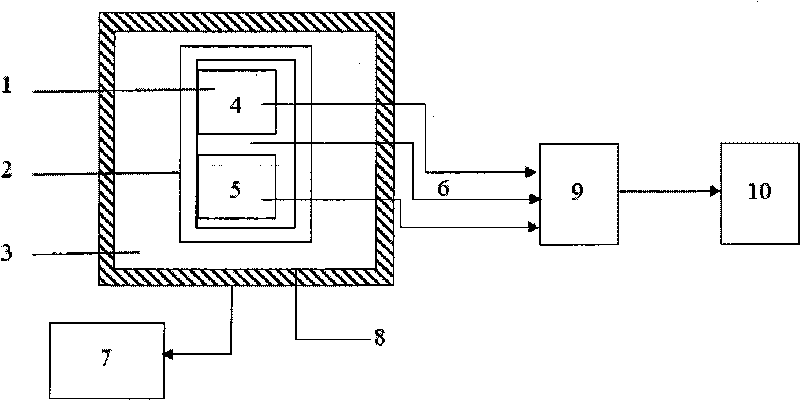

[0073] set up image 3 For the experimental device shown, after connecting the instruments, turn on the digital thermometer and computer using the center309 four-way thermometer, do...

Embodiment 2

[0077] Example 2: Thermal physical property test of LiCl / NaCl high temperature phase change energy storage material

[0078] First weigh 26.08g LiCl and 23.96g NaCl (mass ratio is 1.08:1), mix and grind them and put them into a nickel crucible, then fix the nickel crucible in an iron box and place it in a resistance furnace at 650°C until it is completely melted, take it out After the iron box, bury all the probes of the thermocouples in the molten salt, take out the iron box, bury all the probes of the thermocouples in the molten salt, place them in the center of the crucible without touching the bottom of the crucible, and let it cool naturally. After the molten salt is solidified, the thermocouple is also fixed in it, and the nickel crucible with the thermocouple is fixed on the iron box support.

[0079] The experimental device diagram is the same as in Example 1. After connecting the instruments, open the center309 four-way thermometer and the computer, double-click to op...

Embodiment 3

[0083] Example 3: Ca(NO 3 ) 2 / NaNO 3 Thermophysical property test of high temperature phase change energy storage materials

[0084] First weigh 18.2g Ca(NO 3 )2 and 31.8g NaNO 3 (mass ratio is 4:7), put into nickel crucible after mixing and grinding, then fix this nickel crucible in an iron box and place it in a resistance furnace at 300°C until completely melted, take out the iron box and put all the probes of thermocouples Bury it in the molten salt, take out the iron box, bury all the thermocouple probes in the molten salt, place it in the middle of the crucible, and let it cool naturally without touching the bottom of the crucible. After the molten salt is solidified, the thermocouple is also fixed in it, and the nickel crucible with the thermocouple is fixed on the iron box support.

[0085] The diagram of the experimental device is the same as in Example 1. After connecting the instruments, turn on the center309 four-way thermometer and the computer, double-click ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com