Method for measuring volatility constituent in white wine

A technology for volatile components and liquor, which is applied in the field of stirring rod adsorption extraction and gas chromatography-mass spectrometry, can solve the problem of no systematic research on liquor, and achieve the effect of improving liquor quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

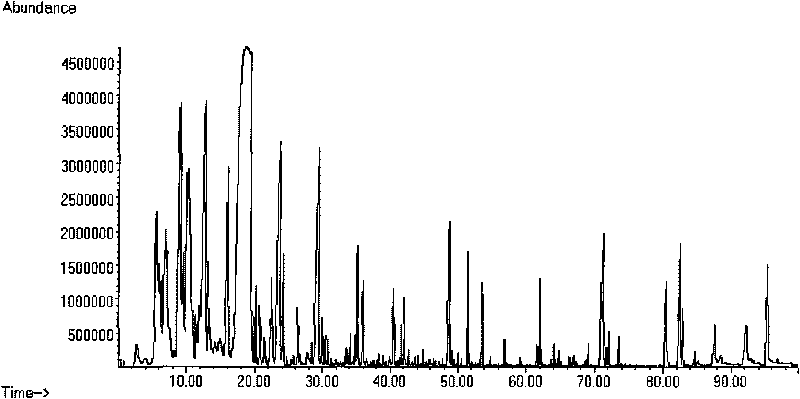

[0019] Dilute the 10-year-old finished wine of a Maotai-flavored liquor with 55% vol to a final alcohol content of 10% vol with deionized water, draw 11 mL of wine sample and place it in a 22 mL sample bottle, add 10 μL of internal standard solution (10 μ L of internal standard solution See instructions for configuration) and 3g of sodium chloride, put in a stirring rod, and tighten the lid. Stir and adsorb at room temperature at a speed of 1000 rpm for 90 min. After the extraction, take out the stirring rod, rinse it with ultrapure water and then dry it with filter paper, transfer the stirring rod to the thermal desorption device for desorption; -FFAP capillary column for separation, temperature program conditions: column temperature 50°C for 2 minutes, 2°C / min to 210°C for 1 minute, then 10°C / min to 230°C for 15 minutes; helium as carrier gas , the flow rate was 24mL / min; the separated samples were identified by Agilent 5975MSD mass spectrometry, mass spectrometry condition...

Embodiment 2

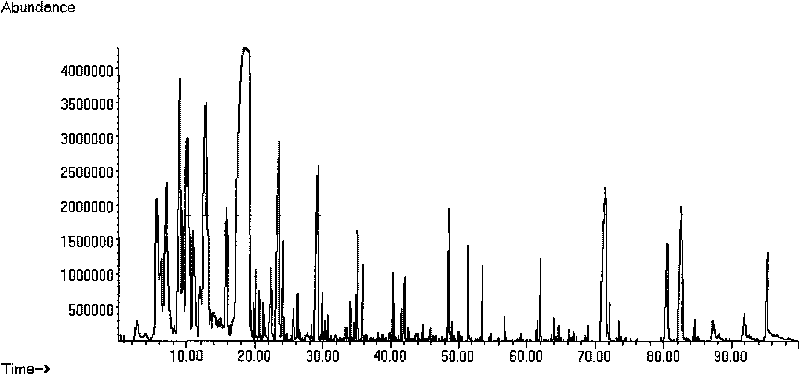

[0025] Dilute the 30-year-old finished wine of a Maotai-flavored liquor with 55% vol to a final alcohol content of 20% vol with deionized water, draw 11 mL of wine sample and place it in a 22 mL sample bottle, add 10 μL of internal standard solution (the See instructions for configuration) and 3g of sodium chloride, put in a stirring rod, and tighten the lid. Stir and adsorb at room temperature at a speed of 1000 rpm for 60 min. After the extraction, take out the stirring rod, rinse it with ultrapure water and then dry it with filter paper, transfer the stirring rod to the thermal desorption device for desorption; -FFAP capillary column for separation, temperature program conditions: column temperature 50°C for 2 minutes, 2°C / min to 210°C for 1 minute, then 10°C / min to 230°C for 15 minutes; helium as carrier gas , the flow rate was 24mL / min; the separated samples were identified by Agilent5975MSD mass spectrometry, mass spectrometry conditions: EI ionization source; electron ...

Embodiment 3

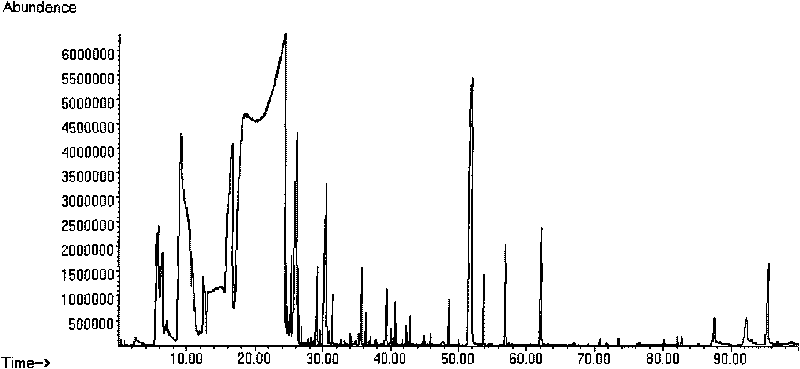

[0033] Dilute 46% vol of a mixed-flavor liquor finished wine with deionized water to a final alcohol content of 5% vol, draw 11 mL of wine sample and place it in a 22 mL sample bottle, add 10 μL of internal standard solution (see the instruction manual for the configuration of internal standard solution) ) and 3g of sodium chloride, put into a stirring rod, and tighten the lid. Stir and adsorb at room temperature at a speed of 1000 rpm for 80 min. After the extraction, take out the stirring rod, rinse it with ultrapure water and then dry it with filter paper, transfer the stirring rod to the thermal desorption device for desorption; -FFAP capillary column for separation, temperature program conditions: column temperature 50°C for 2 minutes, 2°C / min to 210°C for 1 minute, then 10°C / min to 230°C for 15 minutes; helium as carrier gas , the flow rate was 24mL / min; the separated samples were identified by Agilent 5975MSD mass spectrometry, mass spectrometry conditions: EI ionizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com