Process for efficiently concentrating cordycepin

A technology of Cordyceps mycelium and process, which is applied in the directions of medical preparations containing active ingredients, antibacterial drugs, plant/algae/fungus/moss ingredients, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

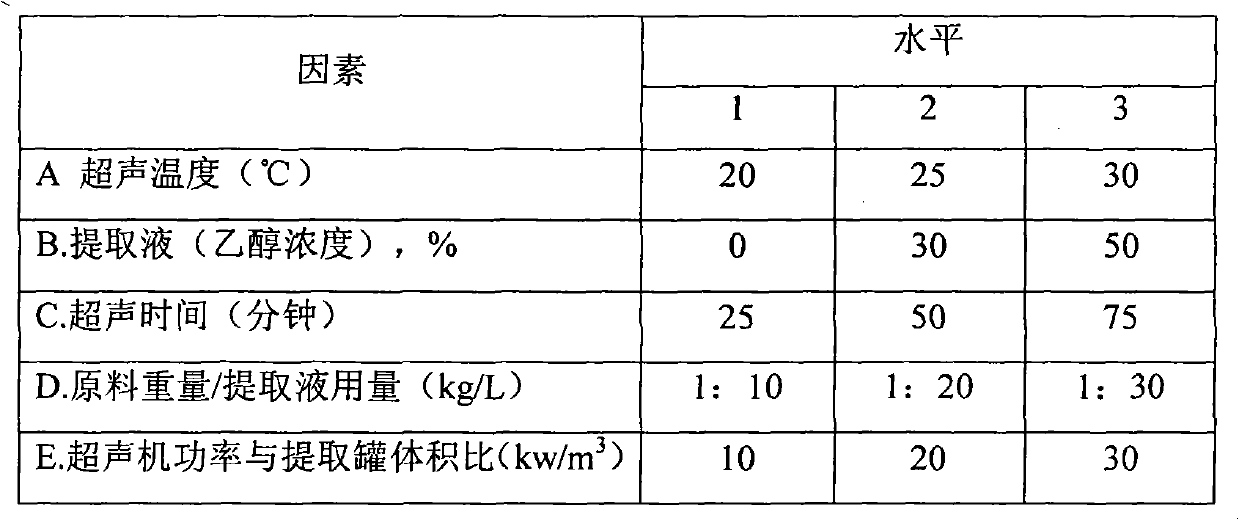

Method used

Image

Examples

Embodiment 1

[0054] Get artificial Cordyceps militaris powder 10kg.

[0055] a. Ultrasonic extraction:

[0056] The ultrasonic temperature is 25°C, the extract is 30% ethanol aqueous solution, the ultrasonic time is 25min, the mass-volume ratio of artificial Cordyceps militaris to the extract is 1:20kg / L, the power of the ultrasonic equipment is 20kw, and the volume of the extraction tank is The ratio is 20kw / m 3 .

[0057] b. Membrane filtration concentration:

[0058] Take the above-mentioned ultrasonic concentrated solution of Cordyceps, control the temperature at 20°C, and perform ultrafiltration. The ultrafiltration membrane adopts a polyamide roll-type membrane with a molecular weight cut-off of 20,000-40,000 Daltons, and the pressure is controlled at 0.4-0.6MPa. Ultrafiltration is performed for 3.5 hours to obtain The concentrated solution after ultrafiltration has a volume of 40% of the original extract.

[0059] c. Freeze drying:

[0060] The concentrated solution after ultra...

Embodiment 2

[0062] Get artificial Cordyceps militaris powder 10kg.

[0063] a. Ultrasonic extraction:

[0064] The ultrasonic temperature is 25°C, the extract is 50% ethanol aqueous solution, the ultrasonic time is 50min, the mass-volume ratio of the artificial Cordyceps militaris to the extract is 1:10kg / L, the power of the ultrasonic equipment is 10kw, and the volume of the extraction tank is The ratio is 10kw / m 3 .

[0065] b. Membrane filtration concentration:

[0066] Take the above-mentioned ultrasonic concentrated solution of Cordyceps, control the temperature at 22°C, and perform ultrafiltration. The ultrafiltration membrane adopts a polyamide roll-type membrane with a molecular weight cut-off of 20,000-40,000 Daltons, and the pressure is controlled at 0.4-0.6MPa. Ultrafiltration is performed for 3.5 hours to obtain The concentrated solution after ultrafiltration has a volume of 30% of the original extract.

[0067] c. Freeze drying:

[0068] The concentrated solution after u...

Embodiment 3

[0070] Get artificial Cordyceps militaris powder 10kg.

[0071] a. Ultrasonic extraction:

[0072] The ultrasonic temperature is 20°C, the extract is 40% ethanol aqueous solution, the ultrasonic time is 75min, the mass-volume ratio of artificial Cordyceps militaris to the extract is 1:30kg / L, the power of the ultrasonic equipment is 30kw, and the volume of the extraction tank is The ratio is 30kw / m 3 .

[0073] b. Membrane filtration concentration:

[0074] Take the above-mentioned ultrasonic concentrated solution of Cordyceps, control the temperature at 24°C, and perform ultrafiltration. The ultrafiltration membrane adopts a polyamide roll-type membrane with a molecular weight cut-off of 20,000-40,000 Daltons, and the pressure is controlled at 0.4-0.6MPa. Ultrafiltration is performed for 3.5 hours to obtain The concentrated solution after ultrafiltration has a volume of 50% of the original extract.

[0075] c. Freeze drying:

[0076] The concentrated solution after ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com