Comprehensive extraction method of glycyrrhiza

A technology of comprehensive extraction and licorice, applied in the field of processing and extraction of herbal plants, can solve the problems of easy residual harmful substances, large consumption of ethanol, backward methods, etc., and achieves the effects of less investment, reduced labor, and simplified methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

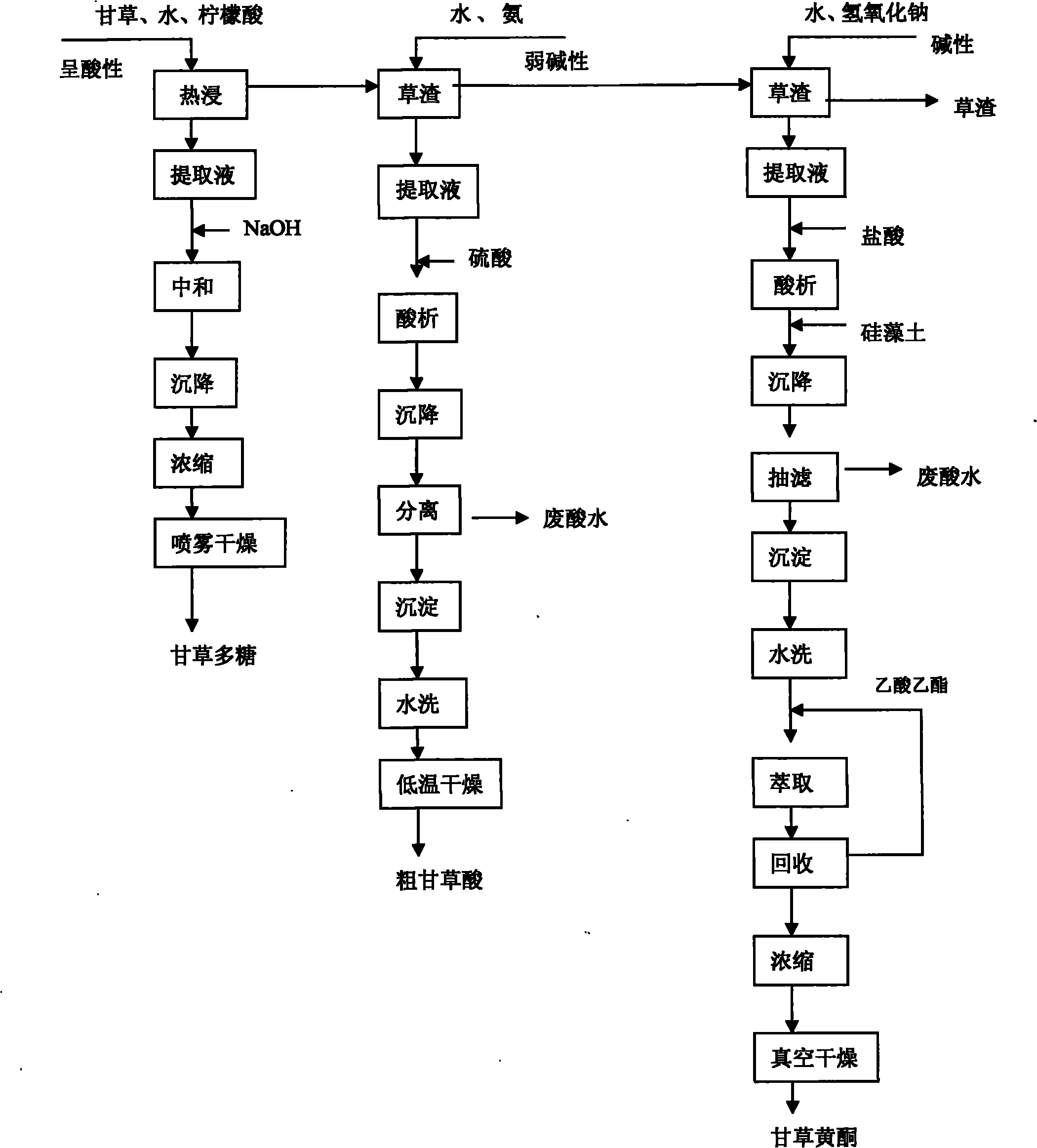

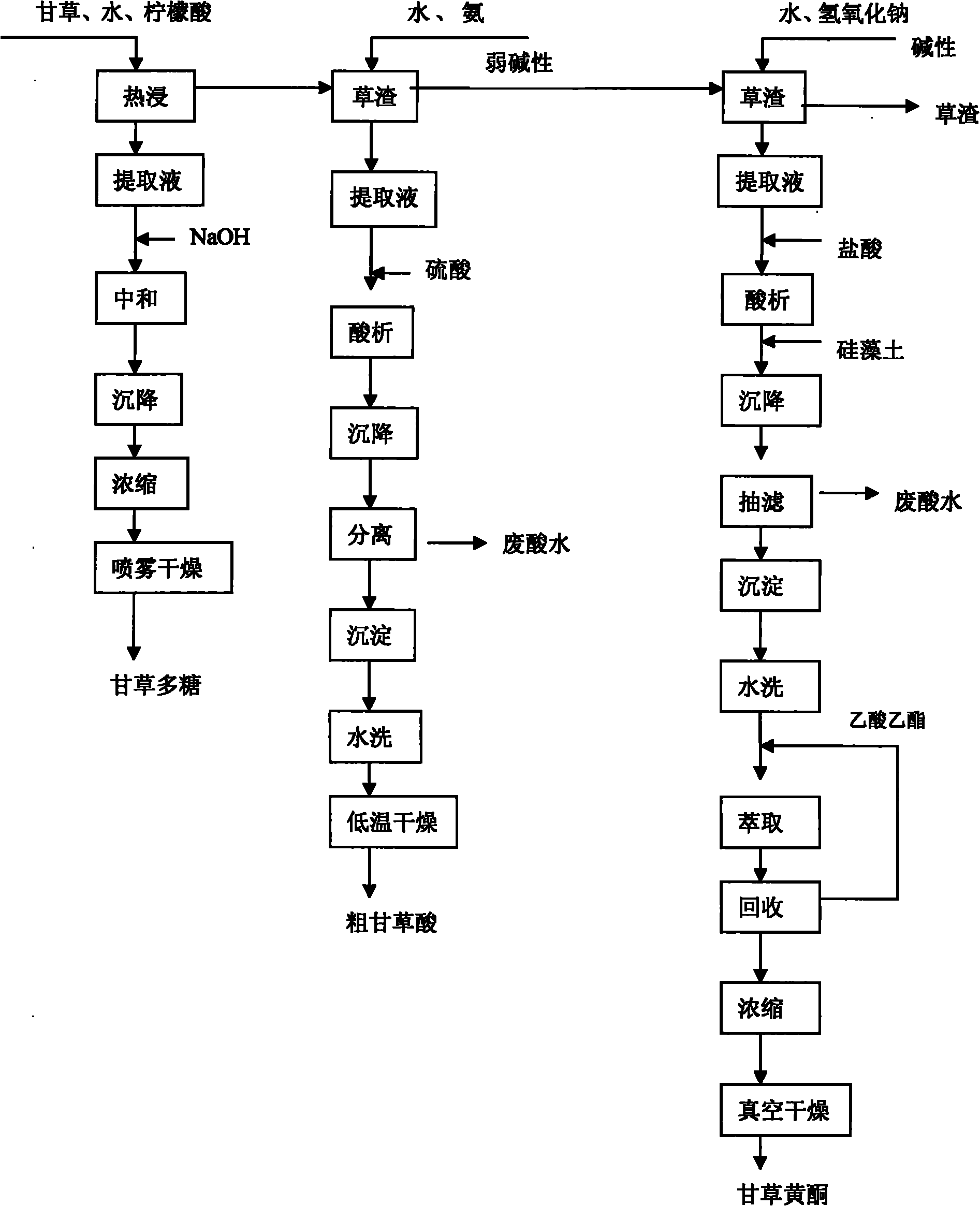

Method used

Image

Examples

Embodiment 1

[0061] 1. Extraction of licorice polysaccharide:

[0062] 1. Hot dip extraction: Pour 800 liters of water into the extraction tank, add 8Kg of citric acid, stir to dissolve, then add 100Kg of crushed licorice, heat to 80°C, keep warm for 2 hours, release the extract, and keep the residue of licorice for later use ;

[0063] 2. Neutralization: Pour the extracted extract into a settling tank, add a 20% NaOH solution to adjust the pH to 5, let it settle for 2 hours, and extract the supernatant;

[0064] 3. Concentration: Put the extracted supernatant into a vacuum concentration tank and concentrate to 16bel (Baume degree);

[0065] 4. Spray-drying: Spray-dry the concentrate to obtain 19.2kg of licorice polysaccharide.

[0066] 2. Extraction of crude glycyrrhizic acid:

[0067] 1. Soaking: add 600 liters of water to the licorice residue after polysaccharide extraction, add ammonia water, adjust the pH to 7, soak at room temperature for 2 hours, stir once every 15 minutes during...

Embodiment 2

[0074] 1. Extraction of licorice polysaccharide:

[0075] 1. Hot dip extraction: Pour 800 liters of water into the extraction tank, add 10Kg of citric acid, stir to dissolve, then add 100Kg of crushed licorice, heat to 85°C, keep warm for 2 hours, release the extract, and keep the licorice residue for later use ;

[0076] 2. Neutralization: Pour the extracted extract into a settling tank, add a 20% NaOH solution to adjust the pH to 5.6, let it settle for 2 hours, and extract the supernatant;

[0077] 3. Concentration: Put the extracted supernatant into a vacuum concentration tank and concentrate to 16bel (Baume degree);

[0078] 4. Spray-drying: Spray-dry the concentrate to obtain 19.2kg of licorice polysaccharide.

[0079] 2. Extraction of crude glycyrrhizic acid:

[0080] 1. Soaking: Add 600 liters of water to the licorice residue after polysaccharide extraction, add ammonia water, adjust the pH to 7.4, soak at room temperature for 2 hours, stir once every 15 minutes duri...

Embodiment 3

[0087] 1. Extraction of licorice polysaccharide:

[0088] 1. Hot-soaking extraction: Pour 800 liters of water into the extraction tank, add 12Kg of citric acid, stir to dissolve, then add 100Kg of crushed licorice, heat to 90°C, release the extract after 2 hours of heat preservation, and leave the residue of licorice spare;

[0089] 2. Neutralization: Pour the extracted extract into a settling tank, add a 20% NaOH solution to adjust the pH to 6, let it settle for 2 hours, and extract the supernatant;

[0090] 3. Concentration: Put the extracted supernatant into a vacuum concentration tank and concentrate to 16bel (Baume degree);

[0091] 4. Spray-drying: Spray-dry the concentrate to obtain 22kg of licorice polysaccharide.

[0092] 2. Extraction of crude glycyrrhizic acid:

[0093] 1. Soaking: Add 600 liters of water to the licorice residue after polysaccharide extraction, add ammonia water, adjust the pH to 8, soak at room temperature for 2 hours, stir once every 15 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com