Aerosol fire extinguishing agent and wet preparation method thereof

A fire extinguishing agent and aerosol technology, applied in the field of aerosol fire extinguishing agent and its wet preparation, can solve the problems of inability to achieve greater breakthrough in mixing uniformity, degree of mixing uniformity dependence, and large environmental impact, so as to improve fire extinguishing efficiency , The effect of improving the fire extinguishing effect and the burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

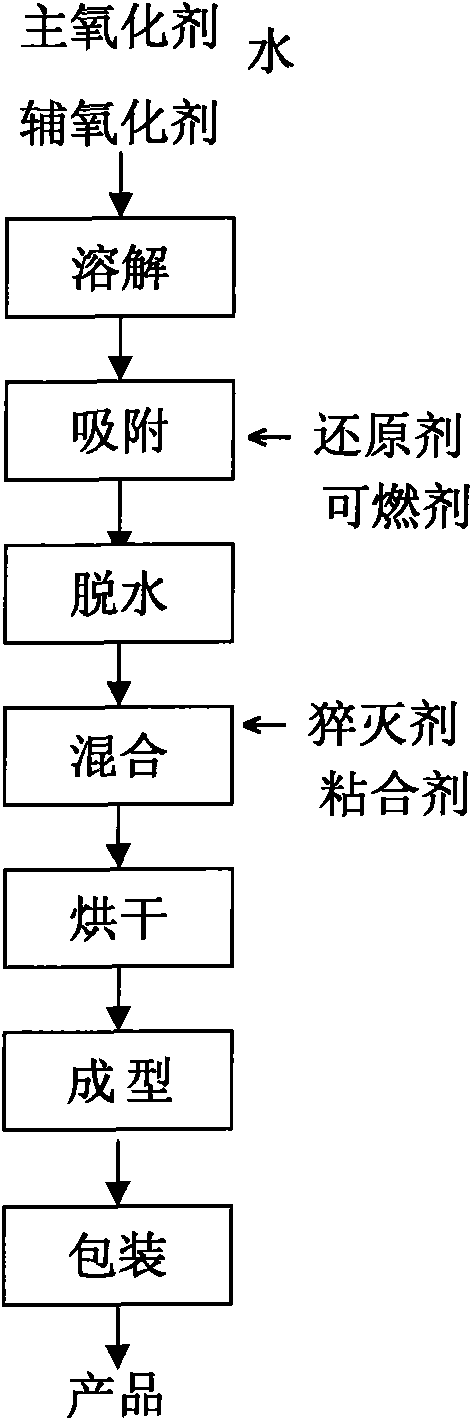

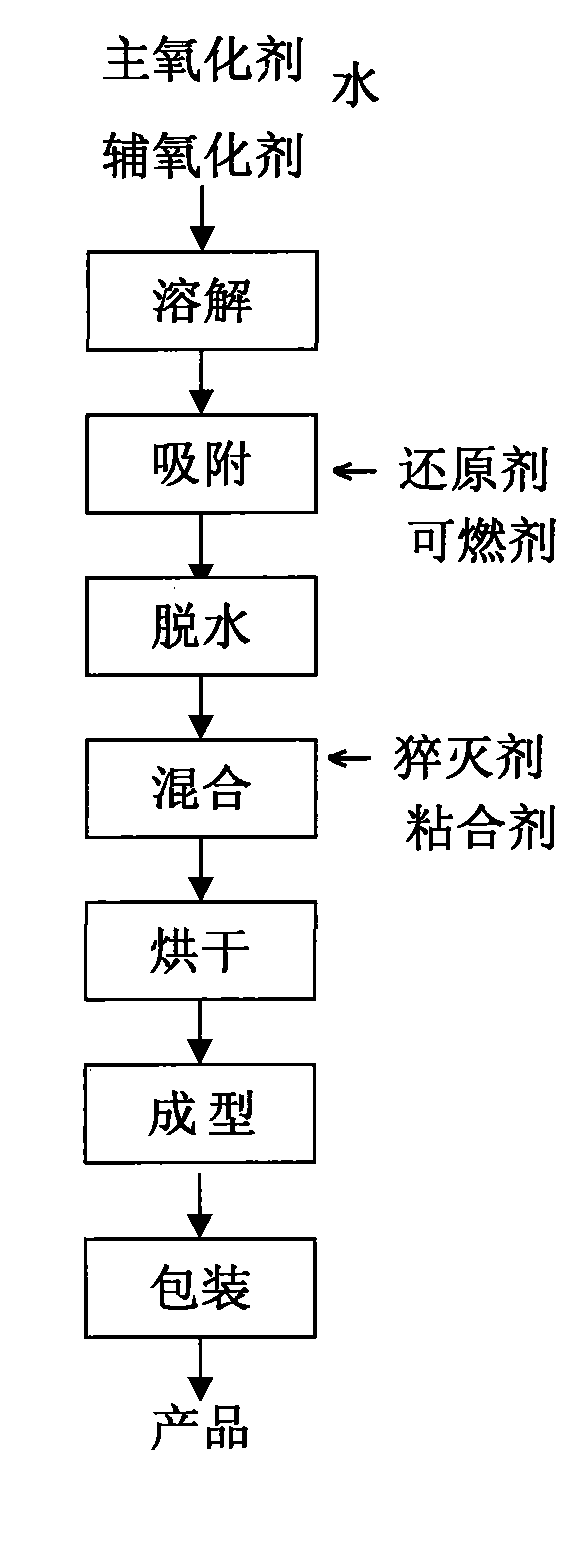

Method used

Image

Examples

Embodiment 1

[0046] 1. Formula (parts by weight):

[0047] 55 main oxidants; 15 auxiliary oxidants; 25 reducing and combustible agents;

[0048] Quencher 0.9; Adhesive 7; Water 80.

[0049] 2. Process steps:

[0050] 1. Dissolution: first add 80 parts of water into the reaction pot, add 55 parts of main oxidant and 15 parts of auxiliary oxidant, fully stir and dissolve into an aqueous solution of oxidant;

[0051] 2. Adsorption: Add 10-25 parts of reducing and combustible agents to the above oxidant aqueous solution, and mix and adsorb for 18-20 minutes under the condition of ultrasonic vibration;

[0052] 3. Dehydration: heating to remove excess water.

[0053] 4. Mixing: Add 0.9 parts of quencher, stir evenly, then add 7 parts of adhesive, stir and mix evenly;

[0054] 5. Drying: Put the mixture into a hot air drum dryer or a vacuum dryer, dry at 75-80°C, and dry the mixture until the water content is less than 1%;

[0055] 6. Molding: molding the dried mixture under pressure in a m...

Embodiment 2

[0057] 1. Formula (parts by weight):

[0058] Main oxidant 50; auxiliary oxidant 10; reduction, combustible 20;

[0059] Quencher 0.6; Adhesive 6; Water 50.

[0060] 2. Process steps:

[0061] 1. Dissolution: First add 50 parts of water into the reaction pot, add 50 parts of main oxidant and 10 parts of auxiliary oxidant, fully stir and dissolve into an aqueous solution of oxidant;

[0062] 2. Adsorption: Add 20 parts of reducing and combustible agents to the above oxidant aqueous solution, and mix and adsorb for 16-18 minutes under the condition of ultrasonic vibration;

[0063] 3. Dehydration: heating to remove excess water;

[0064] 4. Mixing: Add 0.6 parts of quencher, stir evenly, then add 6 parts of adhesive, stir and mix evenly;

[0065] 5. Drying: Put the mixture into a hot air drum dryer or a vacuum dryer, dry at 70-75°C, and dry the mixture until the water content is less than 1%;

[0066] 6. Molding: molding the dried mixture under pressure in a mold to obtain ...

Embodiment 3

[0068] 1. Formula (parts by weight):

[0069] Main oxidant 45; auxiliary oxidant 20; reduction, combustible 15;

[0070] Quencher 0.4; Binder 6; Water 50.

[0071] 2. Process steps:

[0072] 1. Dissolution: First add 50 parts of water into the reaction pot, add 45 parts of main oxidant and 20 parts of auxiliary oxidant, fully stir and dissolve into an aqueous solution of oxidant;

[0073] 2. Adsorption: Add 15 parts of reducing and combustible agents to the above oxidant aqueous solution, and mix and adsorb for 13 to 15 minutes under the condition of ultrasonic vibration;

[0074] 3. Dehydration: heating to remove excess water.

[0075] 4. Mixing: Add 0.4 parts of quencher, stir evenly, then add 6 parts of adhesive, stir and mix evenly;

[0076] 5. Drying: Put the mixture into a hot air drum dryer or a vacuum dryer, dry at 65-70°C, and dry the mixture until the water content is less than 1%;

[0077] 6. Molding: molding the dried mixture under pressure in a mold to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com