Reinforcing fabric for non-woven heat-resisting filter material and purposes thereof

A filter material and heat-resistant technology, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the loss of fiber strength, processing methods without heat setting, and low strength of polytetrafluoroethylene fibers. , to achieve the effect of high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

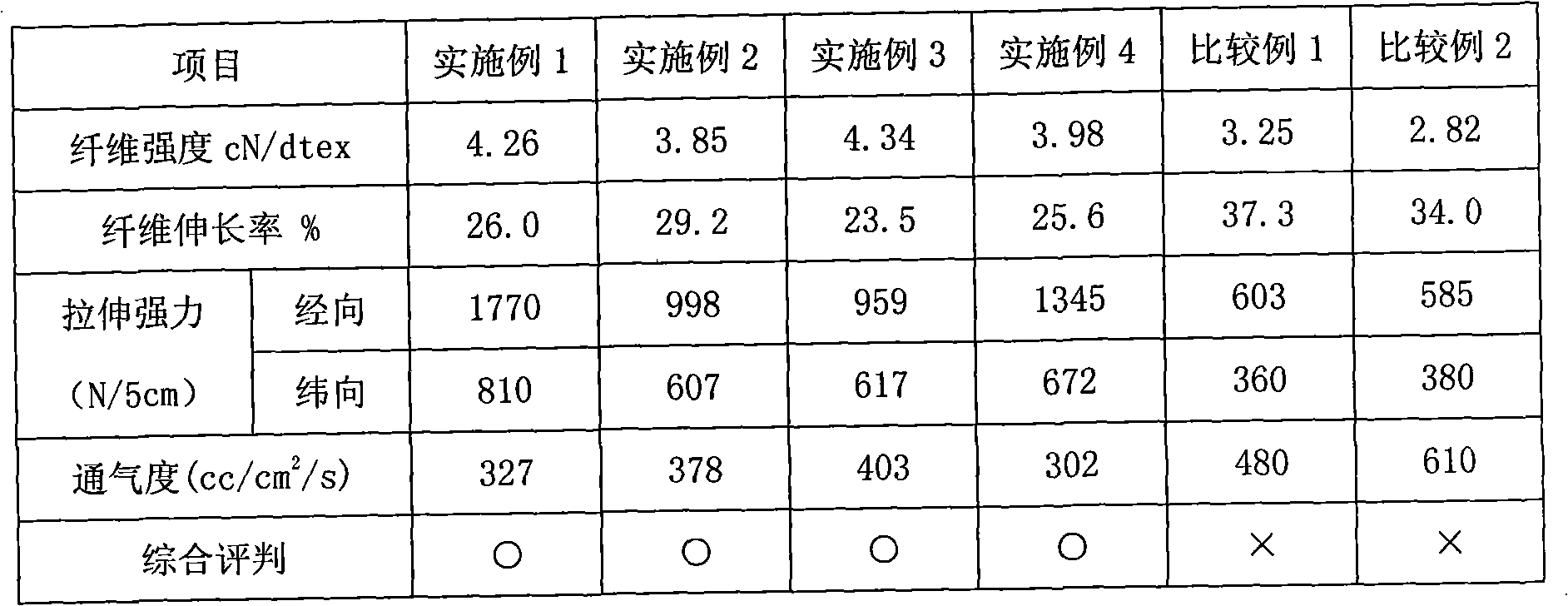

Embodiment 1

[0029] A reinforcing fabric for non-woven heat-resistant filter materials, using polyphenylene sulfide high-strength short fibers (2.2dtex*51mm) Spinning→doubling→twisting process, producing a double-ply yarn with a linear density of 531Denier as a weft yarn, and producing a three-ply yarn with a linear density of 797Denier as a warp yarn. The yarn is then subjected to heat setting treatment (condition: 90°C*25min), warping, weaving and other processes to produce a yarn with a warp density of 33 strands / 2.54cm, a weft density of 17 strands / 2.54cm, and a cover factor of 1155. Reinforced fabric. The results of some physical properties of the reinforced fabric are shown in Table 1 below.

Embodiment 2

[0031] A reinforcing fabric for non-woven heat-resistant filter materials, using polyphenylene sulfide high-strength short fibers (80% content) and polytetrafluoroethylene short fibers (PTFE) (20% content) as raw materials for the reinforcing fabric Through the process of opening→carding→drawing→slubbing→spinning→doubling→twisting, single-ply yarns with a linear density of 760Denier are produced as weft yarns, and double-ply yarns with a linear density of 531Denier are used as warp yarns. towards the yarn. The yarn is then subjected to heat setting treatment (condition: 100°C*35min), warping, weaving and other processes to produce a warp density of 30 threads / 2.54cm, a weft density of 13 threads / 2.54cm, and a cover factor of 1052. Reinforced fabric. The results of some physical properties of the reinforced fabric are shown in Table 1 below.

Embodiment 3

[0033] A reinforcing fabric for non-woven heat-resistant filter materials, which uses polyphenylene sulfide high-strength filament fiber (400Denier-100f) as the raw material of the reinforcing fabric, and the yarn is heat-set (condition: 120°C*30min ), warping, weaving and other processes to produce a reinforced fabric with a warp density of 30 threads / 2.54cm, a weft density of 17 threads / 2.54cm, and a cover factor of 927. The results of some physical properties of the reinforced fabric are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com