Production formula of flame retardant dual density glue and production technique

A production formula and double-density technology, applied in applications, shoe soles, clothing, etc., can solve the problems of easy sticking to rollers, scorching, poor processing performance, easy scorching, etc., and achieve the effect of improving technological content and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

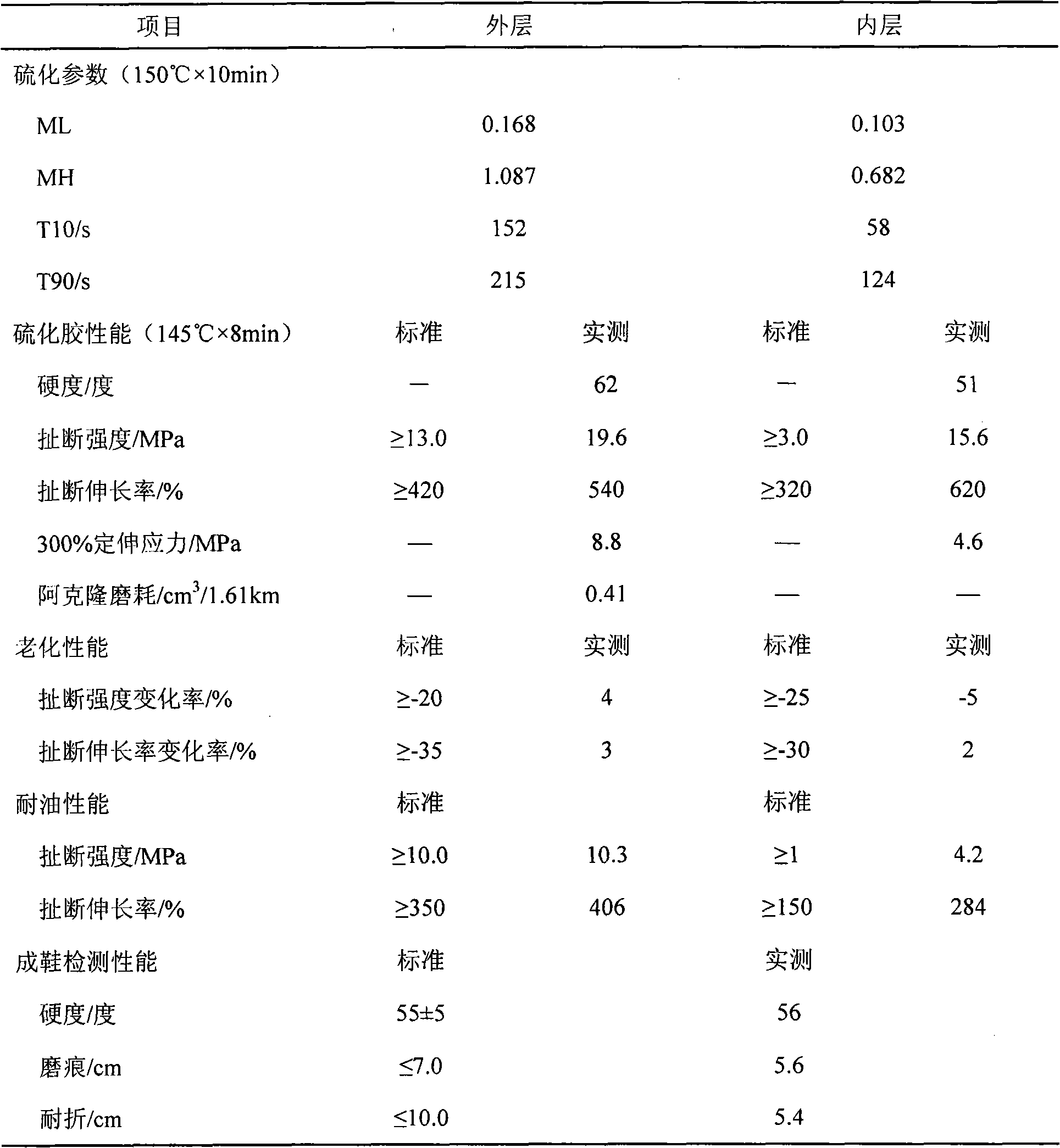

Embodiment 1

[0033] A production formula and process of a flame-retardant double-density rubber compound, including an outer layer rubber compound and an inner layer rubber compound, the outer layer rubber compound is composed of the following raw materials in proportion by weight: natural rubber 30, cis-butadiene rubber 30, Active Zinc Oxide 5, Light Magnesium Oxide 5, Stearic Acid 2, Anti-aging Agent 3, Flame Retardant 13, Terpene Resin 4, Vaseline 2, N339 Carbon Black 12, N330 Carbon Black 30, Transformer Oil 8, Neoprene Rubber 40. Sulfur-80 0.5, accelerator 2.5;

[0034] The inner rubber compound is composed of the following raw materials in proportion by weight: natural rubber 80, active zinc oxide 5, light magnesium oxide 4, stearic acid 2, antioxidant 3, flame retardant 15, petrolatum 3, stearin Zinc acid 3, N326 carbon black 30, 46# engine oil 10, sulfur-802, accelerator 3, foaming agent 1, neoprene 40;

[0035] First, the outer layer rubber compound and the inner layer rubber com...

Embodiment 2

[0057]The outer rubber compound is composed of the following raw materials by weight: 20 natural rubber, 20 butadiene rubber, 3 active zinc oxide, 3 light magnesium oxide, 1 stearic acid, 2 antioxidant, 10 flame retardant, Terpene resin 2, petrolatum 1, N339 carbon black 10, N330 carbon black 25, transformer oil 7, neoprene rubber 30, sulfur-800.2, accelerator 2;

[0058] The inner layer compound is composed of the following raw materials in proportion by weight: natural rubber 70, active zinc oxide 3, light magnesium oxide 3, stearic acid 1, antioxidant 2, flame retardant 13, petrolatum 2, stearin Zinc acid 2, N326 carbon black 20, 46# engine oil 8, sulfur-801, accelerator 2, foaming agent 0.5, neoprene 30.

[0059] The production process is the same as in Example 1.

Embodiment 3

[0061] The outer rubber compound is composed of the following raw materials in proportion by weight: natural rubber 40, butadiene rubber 40, active zinc oxide 7, light magnesium oxide 6, stearic acid 3, antioxidant 4, flame retardant 15, Terpene resin 5, petrolatum 3, N339 carbon black 15, N330 carbon black 35, transformer oil 10, neoprene rubber 50, sulfur-800.8, accelerator 3;

[0062] The inner layer compound is composed of the following raw materials in proportion by weight: natural rubber 90, active zinc oxide 7, light magnesium oxide 6, stearic acid 3, antioxidant 4, flame retardant 18, petrolatum 4, stearin Zinc acid 5, N326 carbon black 40, 46# engine oil 11, sulfur-803, accelerator 4, foaming agent 2, neoprene 50.

[0063] The production process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com