Method for quickly determining water content of particulate materials

A granular material, rapid measurement technology, applied in the field of concrete construction, to achieve the effect of reducing pollution, fast speed and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, measuring the water content of the sand on site.

[0034] a. First, according to the "General Concrete Sand, Stone Quality and Inspection Method Standard", make relevant technical index parameters; that is, the sample is sand in Zone II, with a fineness modulus of 2.68 and an apparent density of 2.65g / cm 3 ;Bulk density 1468kg / m 3 ;

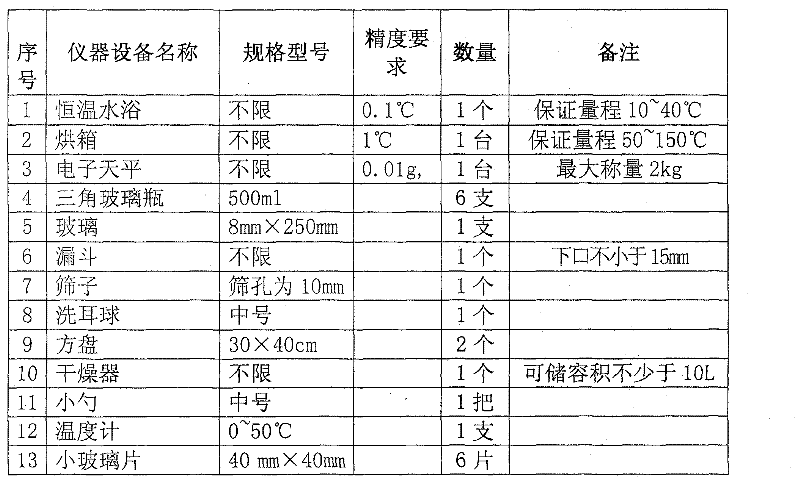

[0035] b. Determine the equipment needed for the test (see Table 1).

[0036] Table 1 Table of instruments and equipment required for sand moisture content

[0037]

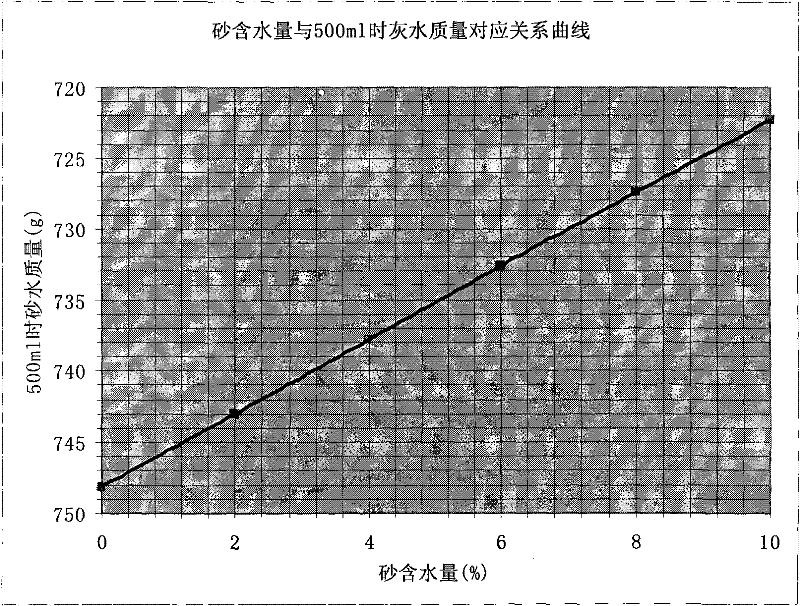

[0038] c. Make a sand standard curve according to the following steps:

[0039] (1) First, according to the corresponding test procedures, inspection methods and standards, dry the pellets to constant weight, and make relevant technical parameters, and pass through a 10mm sieve for use;

[0040] (2), taking 400g of dry sand as the benchmark respectively, according to the water content of 0, 2%, 4%, 6%, 8%, and 10% sand (as long as five or more are selecte...

Embodiment 2

[0066] Embodiment 2, measuring the moisture content of fly ash on site.

[0067] a. Check the relevant standards and parameters of fly ash;

[0068] b. Determine the equipment required for the test (see Table 4)

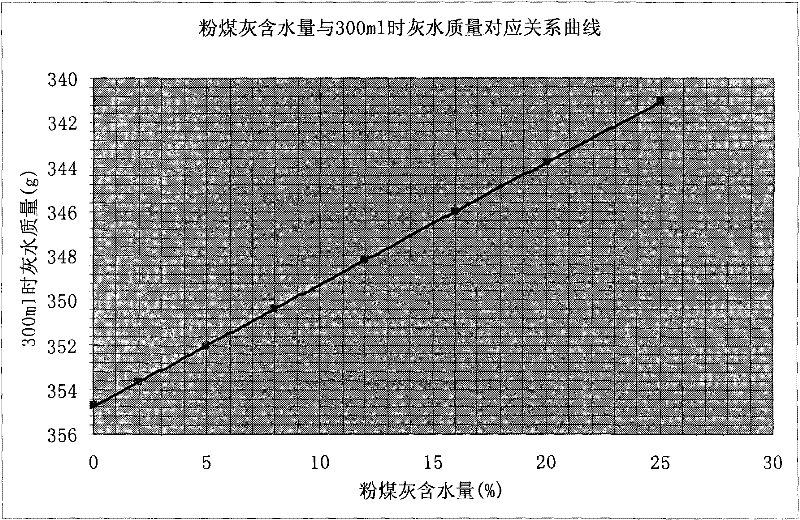

[0069] c. Make the fly ash standard curve according to the following steps:

[0070] (1) According to the corresponding test procedures, inspection methods and standards, take about 1500g of representative fly ash and dry it to constant weight, and make relevant technical parameters;

[0071] (2), take 100g dry fly ash as benchmark respectively, take dry fly ash quality by the water content of 0,2%, 5%, 8%, 12%, 16%, 20%, 25% fly ash, namely : 100g, 98g, 95g, 92g, 88g, 84g, 80g, 75g;

[0072] (3), take eight 250ml triangular flasks, calibrate the quality of the empty triangular flasks with glass flakes, and mark the bottle and glass flake numbers;

[0073] (4) Add about 200ml of water to each of the eight calibrated triangular flasks, put the dry fly ash mass cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com