Armored heating cable

A technology of armored heating cable and heating core, applied in the field of armored heating cable, can solve the problems of durability, high temperature resistance mechanical properties not up to standard, cable yield and insulation reduction, and long processing time, etc. Yield and insulation, good mechanical properties, and the effect of twist resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

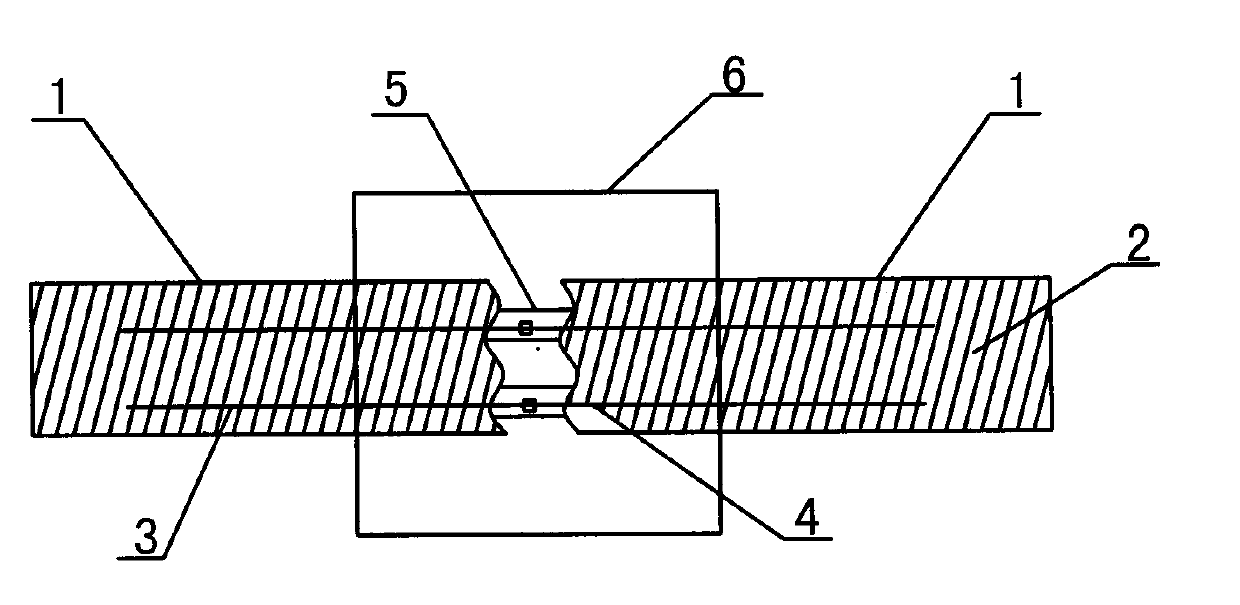

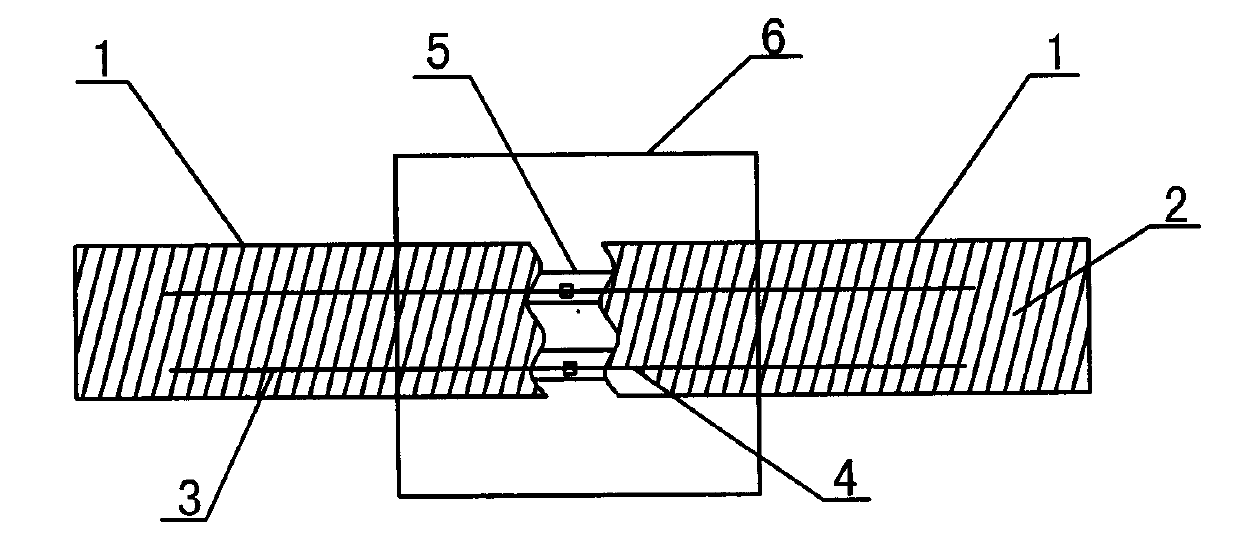

[0011] like figure 1 As shown, the armored heating cable of the present invention includes a metal sheath 1 and an inorganic insulating layer 2, the metal sheath 1 is composed of seamless continuous stainless steel or copper tubes, and an inorganic insulating layer 2 is arranged inside it. The inorganic insulating layer 2 is composed of high-purity, high-temperature, fused crystalline magnesium oxide, and a single or multiple alloy heating wires are arranged inside it as the heating core wire 3; the other end of the metal sheath 1 is provided with a cold-end core wire 4 , The middle joint end of the metal sheath 1 is provided with a metal connection sleeve 6 and a mica paper 5 is provided inside it. Current passes through the series resistance heating core of the cable to generate heat, so it can generate heat evenly; the stainless steel sheath can meet the needs of high temperature conditions and large heating power, as well as the needs of high temperature conditions and lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com