Oxygen reduction catalyst prepared from grapheme modified by macrocyclic compound, and preparation method thereof

A technology of macrocyclic compounds and cyclic compounds, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the cost and durability of platinum catalysts and cannot achieve large-scale Application, unsuitable for mass production, complex reaction conditions, etc., to achieve the effects of low cost, moderate processing conditions, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The graphene used in the present invention can be prepared by the following method, but is not limited to the following method.

[0027] Add 5 g of graphite to 87.5 mL of concentrated sulfuric acid and 45 mL of concentrated nitric acid and mix uniformly in an ice bath, then slowly add 55 g of potassium chlorate to the mixture, and continue stirring at room temperature for 96 hours to obtain graphite oxide. After the graphite oxide was dried at 80°C, it was peeled off in deionized water ultrasonically (60KHz). The obtained material was reacted with hydrazine hydrate (1 μL: 3 mg) at 80° C. for 24 hours to obtain graphene flakes.

Embodiment 2

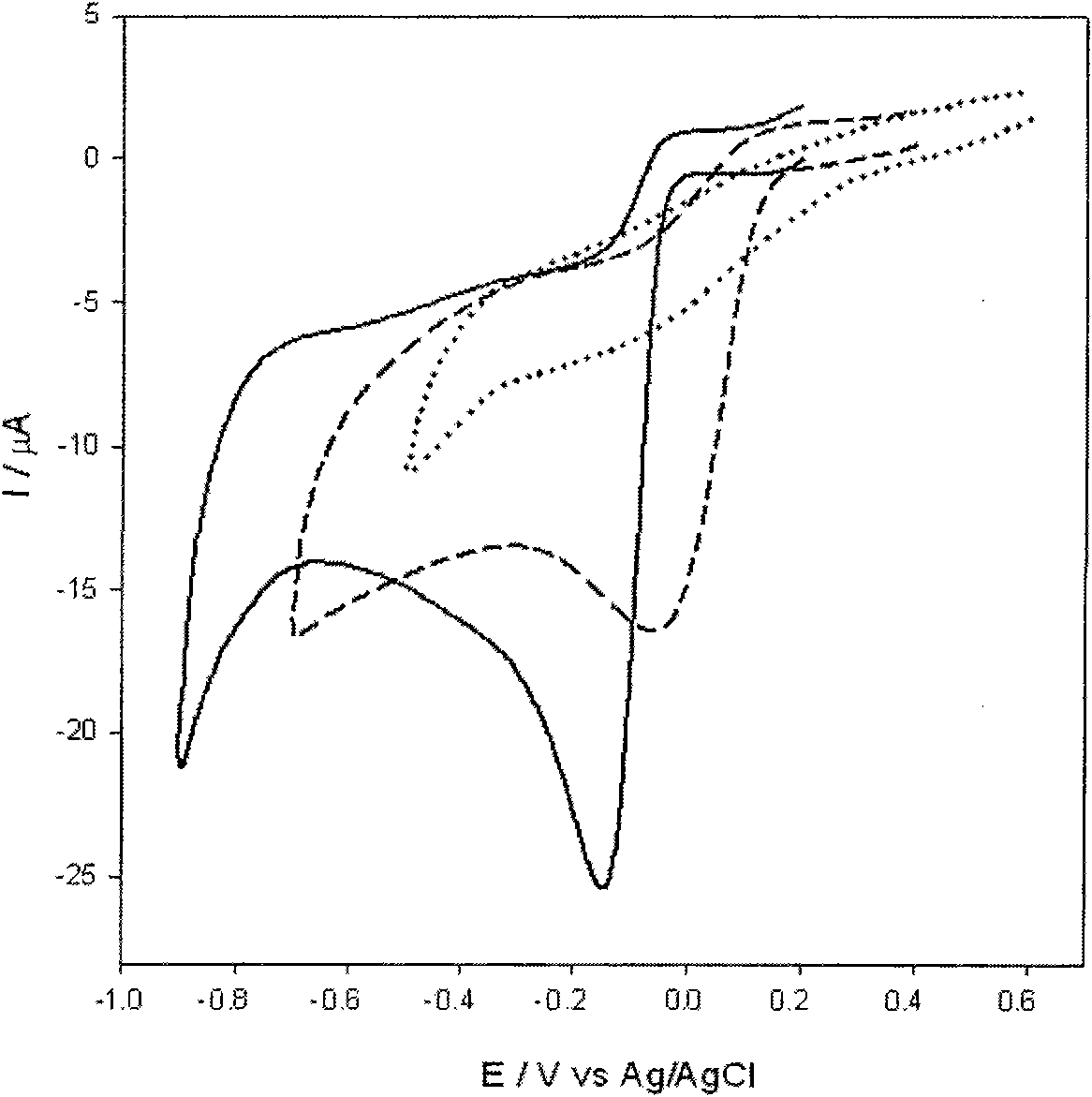

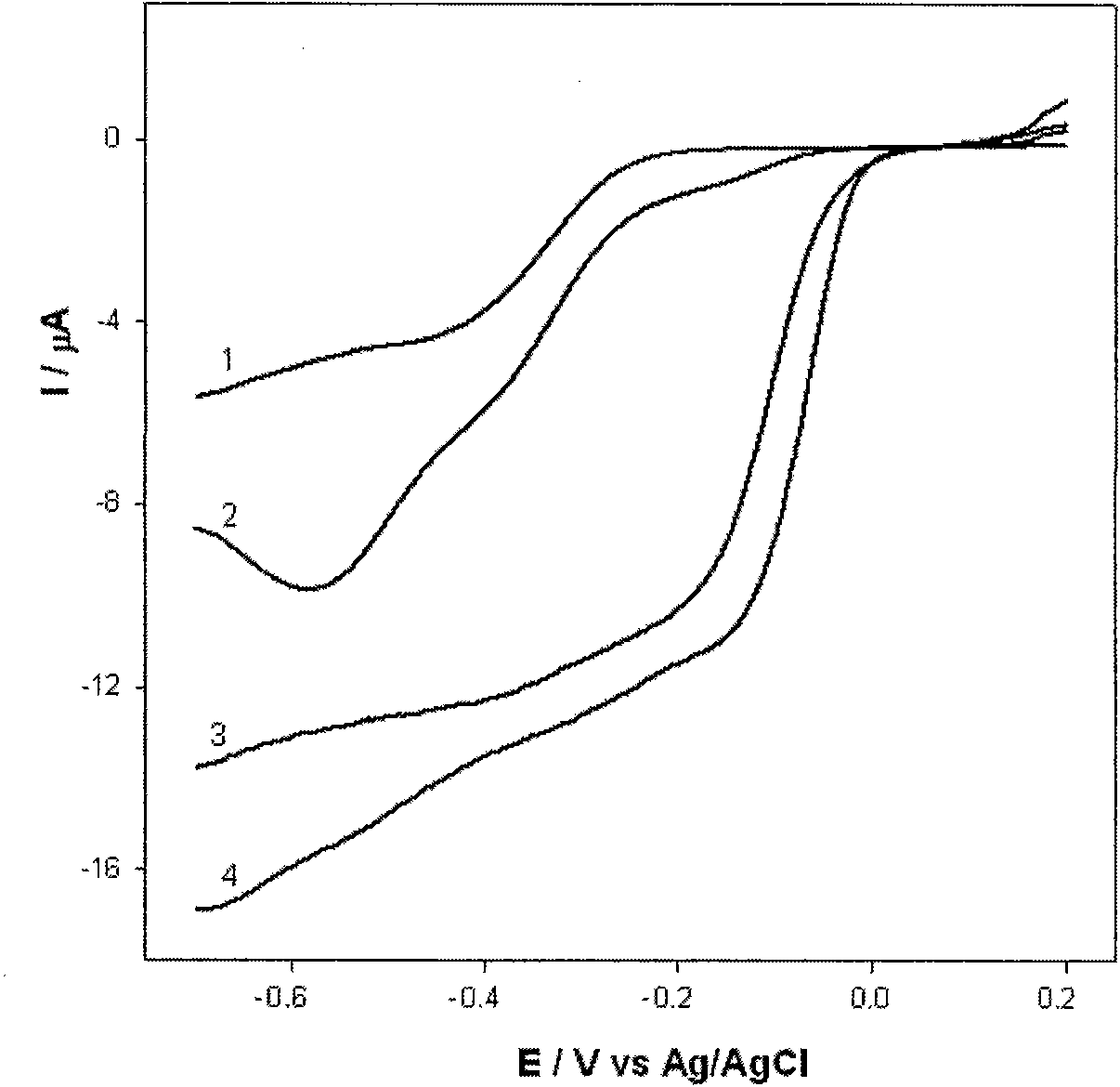

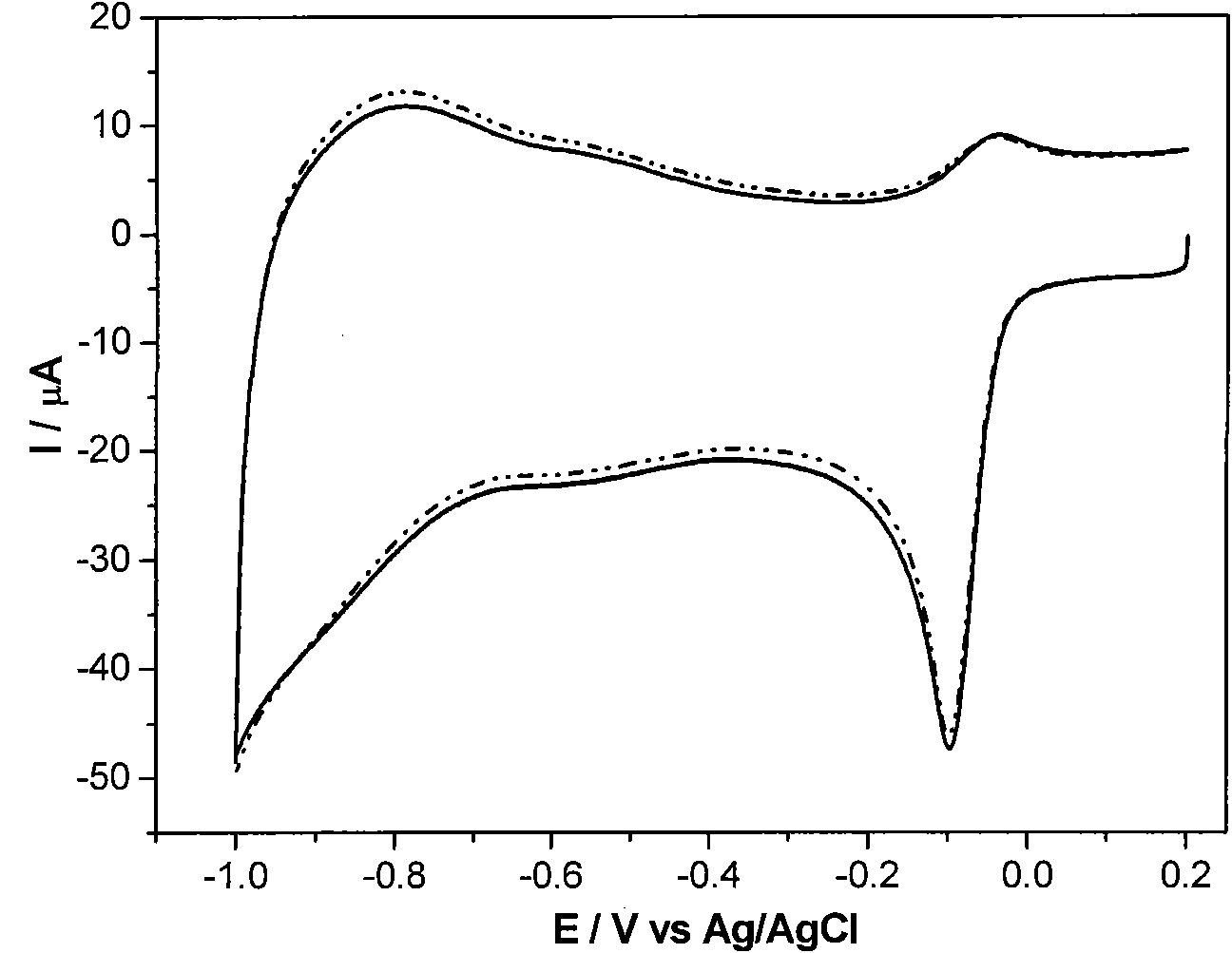

[0029] After 2 mg of graphene and 5 mg of iron phthalocyanine (purchased from sigma aldrich) were dispersed in 10 mL of water at 60 KHz ultrasonic for 20 hours, the resulting suspension was filtered with a filter membrane with a pore size of 0.45 μm. The sample obtained after filtration was repeatedly washed with distilled water to wash away the unadsorbed iron phthalocyanine. Then the sample was dried at 80°C to obtain the phthalocyanine iron graphene composite.

Embodiment 3

[0031] The preparation of the phthalocyanine iron-graphene composite was as described in Example 2. The prepared phthalocyanine iron-graphene composite was dispersed in water to obtain a 2 mg / mL suspension. Take 4μL of the suspension and apply dropwise to the surface of the glassy carbon electrode. After the electrode is dried at room temperature, a glassy carbon electrode modified with a composite of graphene and iron phthalocyanine is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com