Device and method for shaping amorphous alloy thin-wall slim pipe

A technology of amorphous alloy and slender tubes, which is applied in the field of forming devices for slender amorphous alloy tubes, can solve the problems of thin walls that cannot be filled, and achieve the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

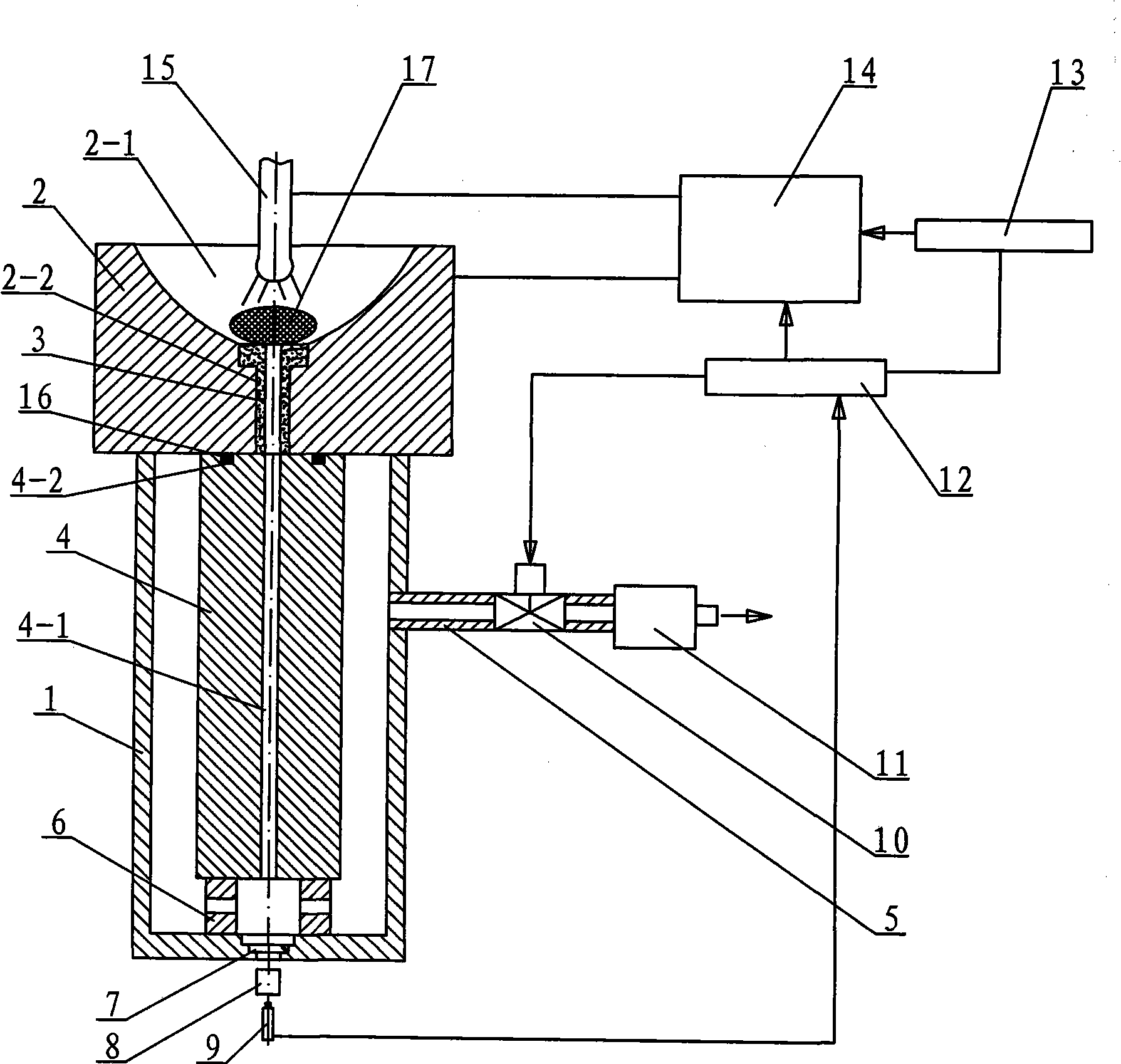

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes an arc melting furnace 1, a copper crucible 2, a graphite tube 3, a connecting pipe 5, a support pad 6, a quartz glass 7, a temperature measuring device 8, an infrared sensor 9, a suction casting valve 10, and a mechanical pump 11 , tungsten rod 15, metal mold 4, suction casting controller 12 and melting current controller 13, one end of the connection pipe 5 is arranged on the side wall of the arc melting furnace 1, and the other end of the connection pipe 5 is connected with the mechanical pump 11, suction casting The valve 10 is installed on the connecting pipe 5, the quartz glass 7 is installed in the bottom center hole of the arc melting furnace 1, the temperature measuring device 8 is located below the bottom center hole of the arc melting furnace 1, and the infrared sensor 9 is located below the temperature measuring device 8, The upper end surface of...

specific Embodiment approach 2

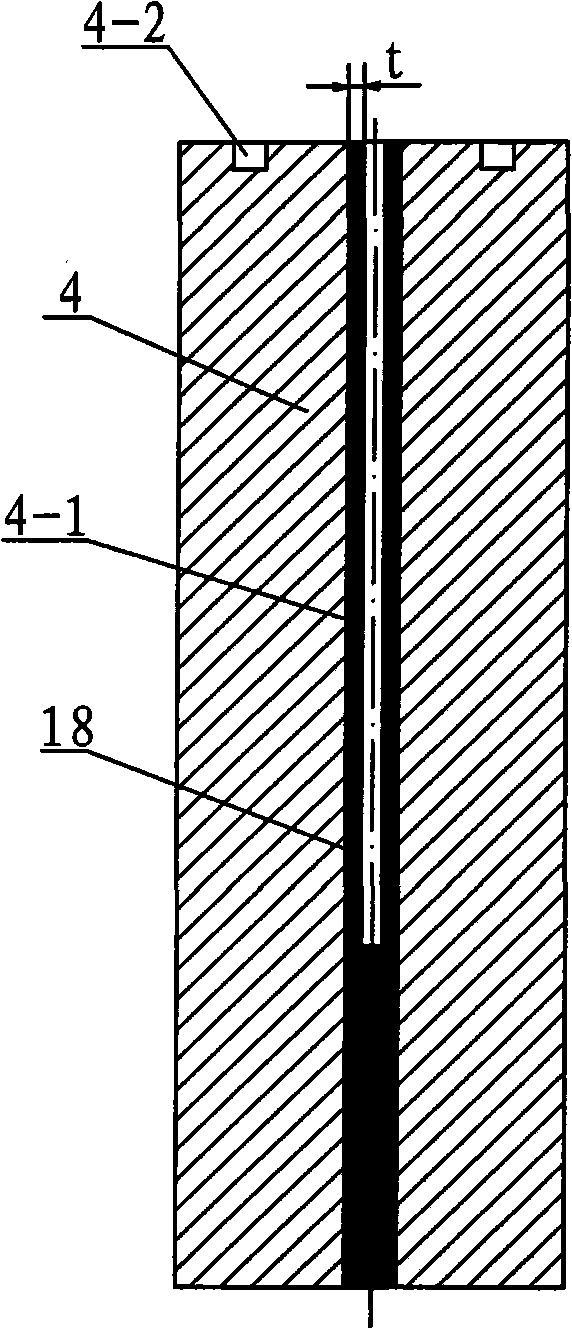

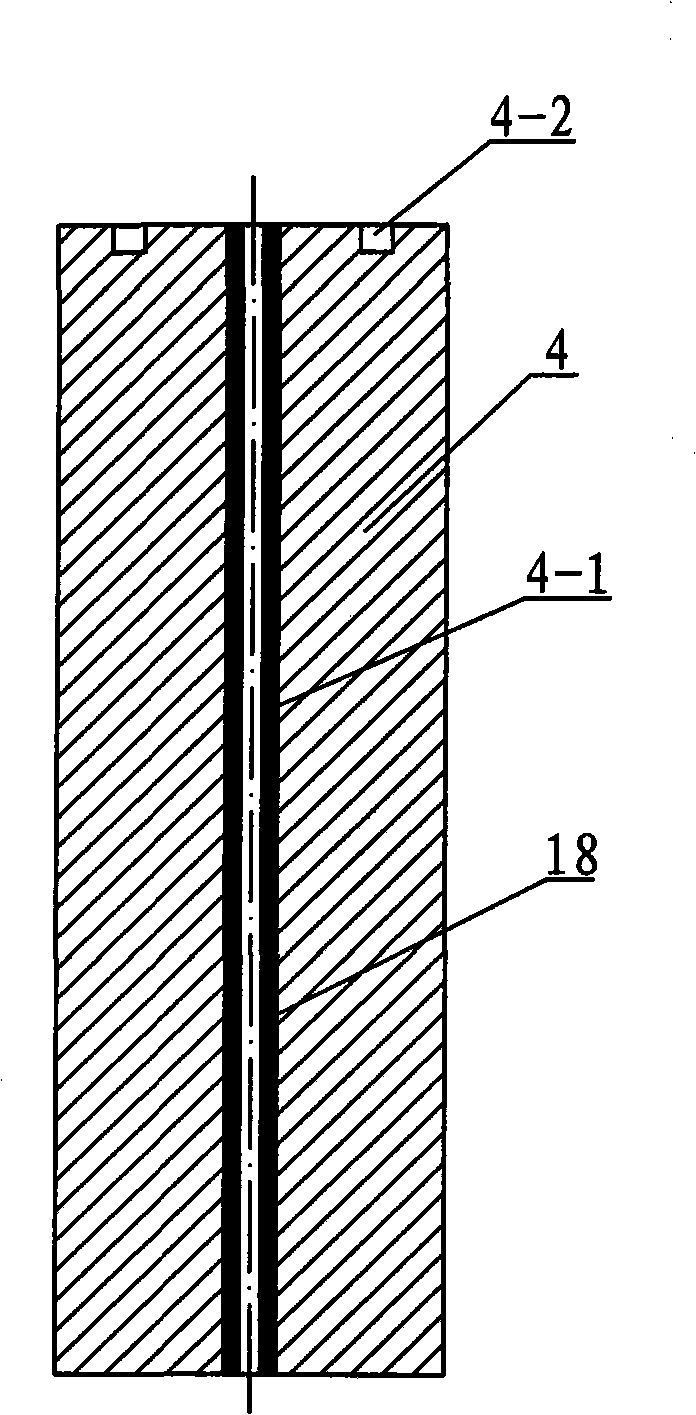

[0009] Specific implementation mode two: combination Figure 1 ~ Figure 3 The present embodiment will be described. The inner diameter of the cavity 4 - 1 of the die 4 of the present embodiment is Φ3 mm, and the length of the die 4 is 250 mm. The present invention is suitable for preparing thin-walled amorphous alloy tubes, and when the inner diameter of the mold cavity 4-1 and the length of the metal mold 4 are at the above-mentioned values, the thin-walled thin-walled elongated amorphous alloy tube has the best effect. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment one is: the device is also added with a gasket 16, the upper end surface of the metal mold 4 is provided with an annular groove 4-2, and the gasket 16 is installed in the annular groove 4-2. 2 in. This design increases the sealing performance between the lower end surface of the copper crucible 2 and the upper end surface of the metal mold 4 . Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com