Micro-pore aeration system

A technology of microporous aeration and air distribution pipes, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve performance and technical deficiencies, large impact area, increase air resistance loss, etc. problems, achieve high oxygenation efficiency and power efficiency, low production cost, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

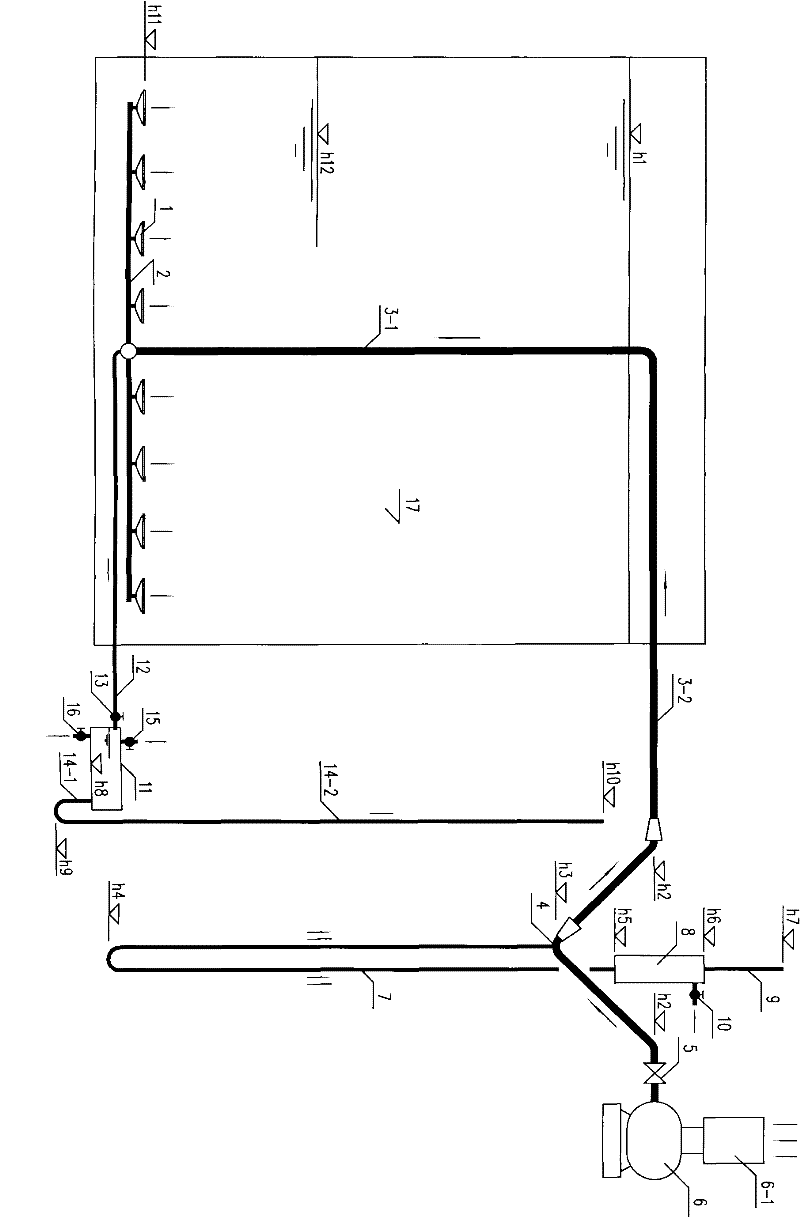

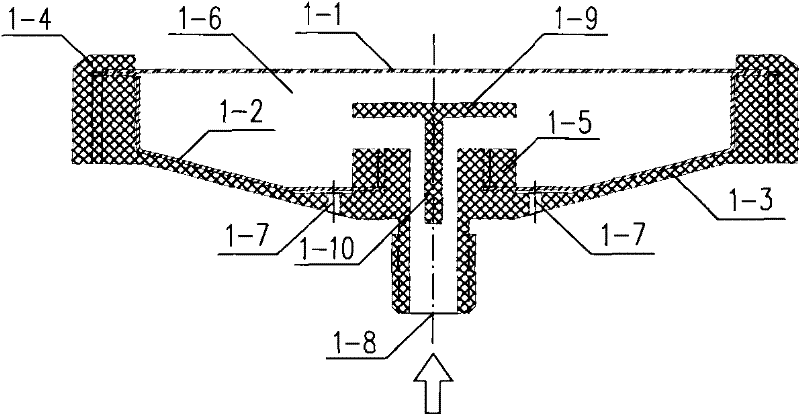

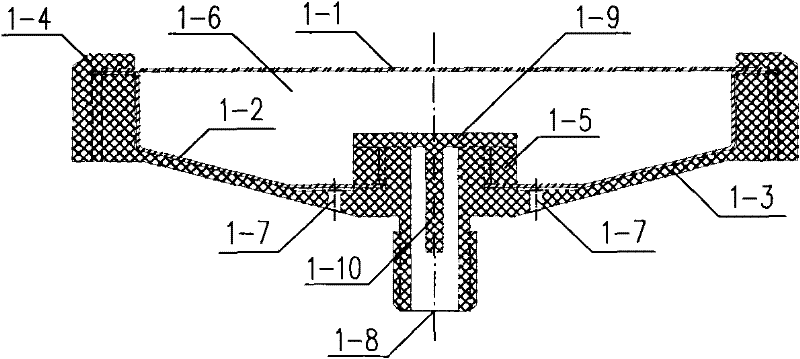

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] When the pipeline system is equipped with a water seal safety device, the lifting check valve plate 1-9 and the positioning slide bar 1-10 of the microporous aeration device 1 can be cancelled.

[0035] 1. System flow

[0036] A microporous aeration system is used for aerobic aeration in sewage biochemical treatment.

[0037] According to Figure-1 and the above, the working conditions of the present invention are divided into aeration operating conditions, intermittent working conditions and initial working conditions, which are described as follows:

[0038] 1. Aeration operating conditions

[0039] After the air is cleaned by the air filter 6-1, it is pressurized by the blower 6, and passes through the main valve 5, the Y-shaped tee pipe 4, the air supply main pipe 3-2, 3-1, the air distribution pipe network 2, and the microporous aeration T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com