Moisture cured multi-constituties grafting solvent-based adhesive

A moisture-curing, solvent-based technology, applied in the direction of graft polymer adhesives, adhesive types, adhesives, etc. Problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

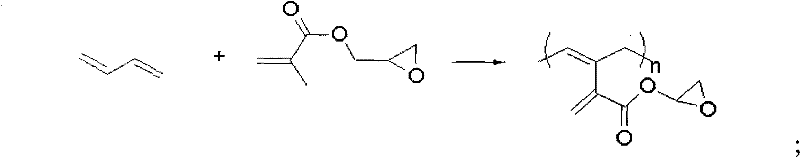

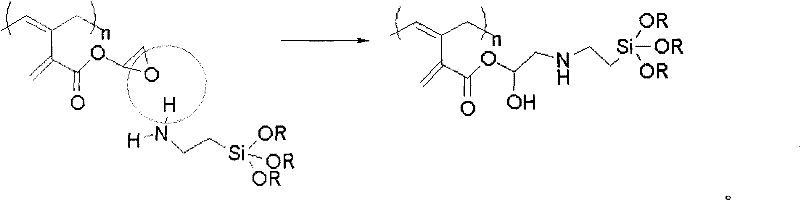

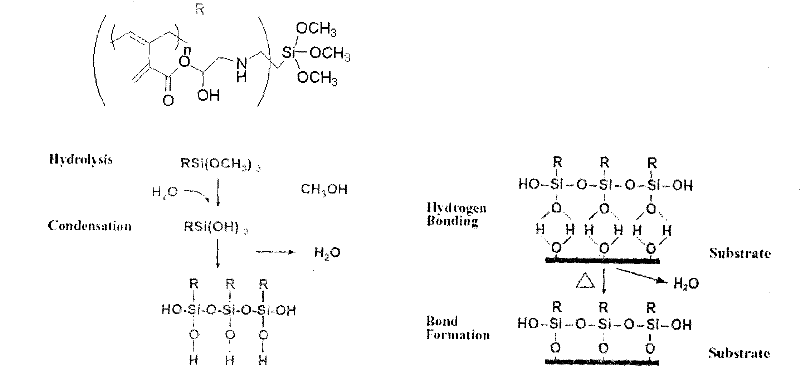

Method used

Image

Examples

Embodiment 1

[0055] Prepare the moisture-curing multi-component grafting solvent-based adhesive according to the following steps:

[0056] (1) Add 31.00g MCH and 10.00gMMA to a reaction kettle with a stirrer and a condenser, stir evenly, add 8.00g CR rubber (brand A-90) and 1.50g SIS rubber (brand 5516), and heat up to 70℃~80℃, stir at this temperature until a transparent liquid A is obtained;

[0057] (2) Add 0.06g benzoyl peroxide (brand BPO-50) in transparent clear liquid A, stir 10 minutes, obtain mixed solution I;

[0058] (3) 0.27g GMA, 0.14g AM and 4.90g MMA were dissolved in 2.97g MCH to obtain solution B;

[0059] (4) Add solution B dropwise to mixed solution I at a rate of 1 drop / 6 seconds, and control the temperature at 82°C to 87°C. After adding solution B, continue stirring for 90 minutes at this temperature to obtain mixed solution II;

[0060] (5) 8.75g of petroleum resin, 1.15g of terpene resin, 0.20g of antioxidant 1010, and 0.20g of antioxidant A-168 were dissolved in ...

Embodiment 2

[0075] Prepare the moisture-curing multi-component grafting solvent-based adhesive according to the following steps:

[0076] (1) Add 30.00g MCH and 10.00gMMA to a reaction kettle with a stirrer and a condenser, stir evenly, add 7.92g CR rubber (brand A-90) and 1.58g SBS rubber (brand 3206), and heat up to 70℃~80℃, stir at this temperature until a transparent liquid A is obtained;

[0077] (2) Add 0.08g benzoyl peroxide (brand BPO-50) in transparent clear liquid A, stir for 10 minutes, obtain mixed solution I;

[0078] (3) 0.27g GMA, 0.14g AM and 4.70g MMA were dissolved in 3.95g MCH to obtain solution B;

[0079] (4) Add solution B dropwise to mixed solution I at a rate of 1 drop / 6 seconds, and control the temperature at 82°C to 87°C. After adding solution B, continue stirring for 90 minutes at this temperature to obtain mixed solution II;

[0080] (5) 7.40g of petroleum resin, 2.46g of terpene resin, 0.20g of antioxidant 1010, and 0.20g of antioxidant 168 were dissolved i...

Embodiment 3

[0095] Prepare the moisture-curing multi-component grafting solvent-based adhesive according to the following steps:

[0096] (1) Add 32.00g MCH and 10.00gMMA to a reaction kettle with a stirrer and a condenser, stir evenly, add 7.02g CR rubber (brand A-90) and 1.42g SBS rubber (brand 3206), and heat up to 70℃~80℃, stir at this temperature until a transparent liquid A is obtained;

[0097] (2) Add 0.06g benzoyl peroxide (brand BPO-50) in transparent clear liquid A, stir 10 minutes, obtain mixed solution I;

[0098] (3) 0.27g GMA, 0.14g AM and 4.70g MMA were dissolved in 2.97g MCH to obtain solution B;

[0099] (4) Add solution B dropwise to mixed solution I at a rate of 1 drop / 6 seconds, and control the temperature at 82°C to 87°C. After adding solution B, continue stirring for 90 minutes at this temperature to obtain mixed solution II;

[0100] (5) 8.71g of petroleum resin, 1.20g of terpene resin, 0.20g of antioxidant 1010, and 0.20g of antioxidant 168 were dissolved in a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com