Method of applying polyethyleneimine as titanium carbonitride based cermet mixed material dispersant

A polyethyleneimine and titanium carbonitride technology, applied in the field of polyethyleneimine as a titanium carbonitride-based cermet dispersant, can solve the problems of unsatisfactory formability and high pressing pressure, and achieve improved density distribution. Effects of uniformity, porosity reduction, dispersion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

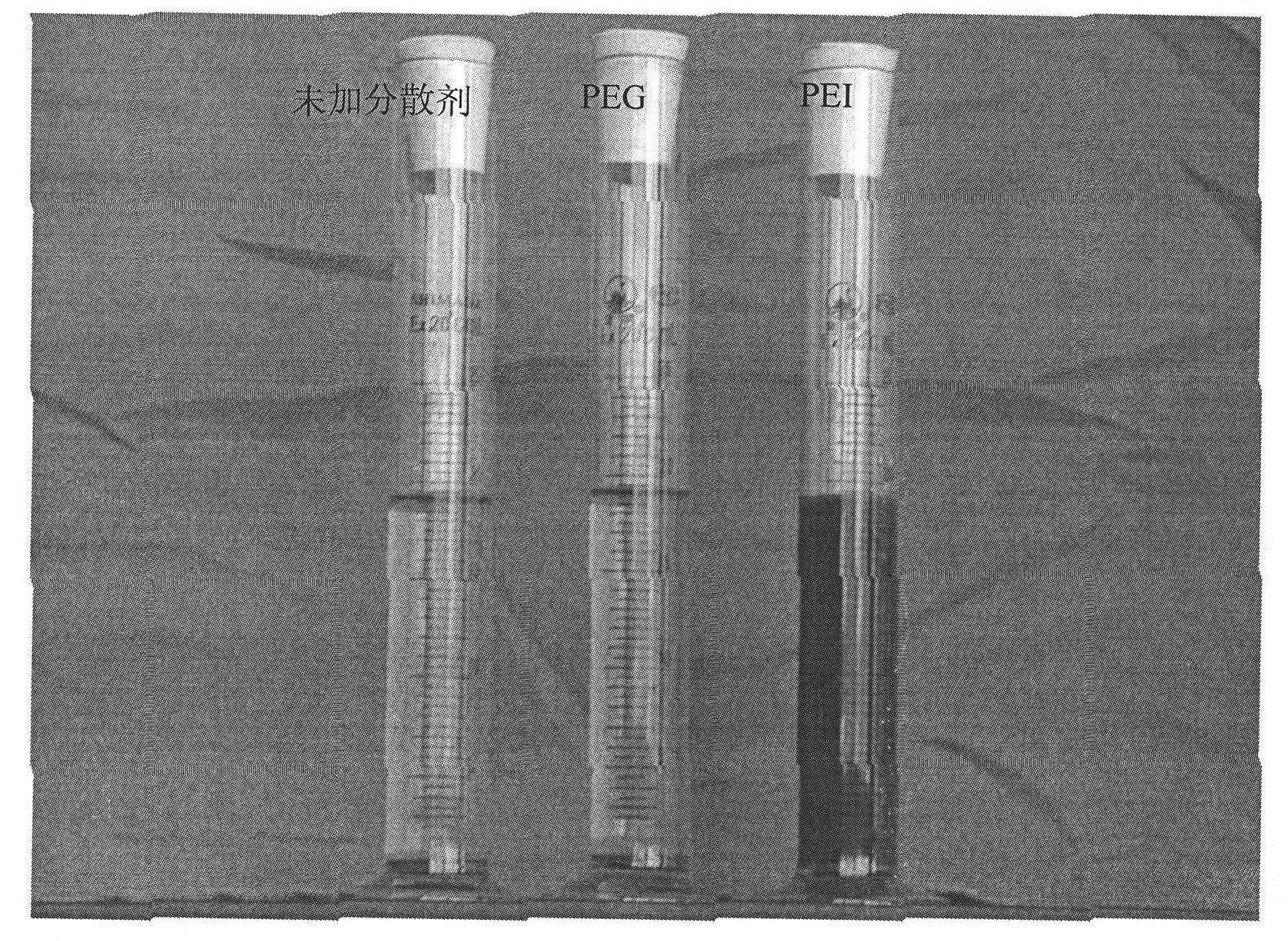

[0013] Example 1: Prepare 0.5075 g of cermet mixed powder according to Table 1, add 20 mL of absolute ethanol, and add 0.0350 wt % polyethyleneimine (PEI) and polyethylene glycol (PEG) to the mixed powder respectively. The slurry configured in the beaker was vibrated in an ultrasonic biochemical analyzer for 20 minutes, and quickly poured into a 25ml measuring cylinder for sedimentation observation. The quality of the dispersibility is qualitatively evaluated by observing the sedimentation of the powder. If the sedimentation phenomenon is not obvious, the better the dispersion, the more stable the slurry is; otherwise, the slurry is unstable.

[0014] figure 1 It is a sedimentation photo of Ti(C,N)-based cermet mixed powder added with 0.0350wt% PEI, 0.0350wt% PEG and no dispersant in absolute ethanol after standing for 24h. From figure 1 It can be seen from the figure that PEI can greatly improve the dispersion of the slurry. After adding PEI, the slurry is very stable. Afte...

example 2

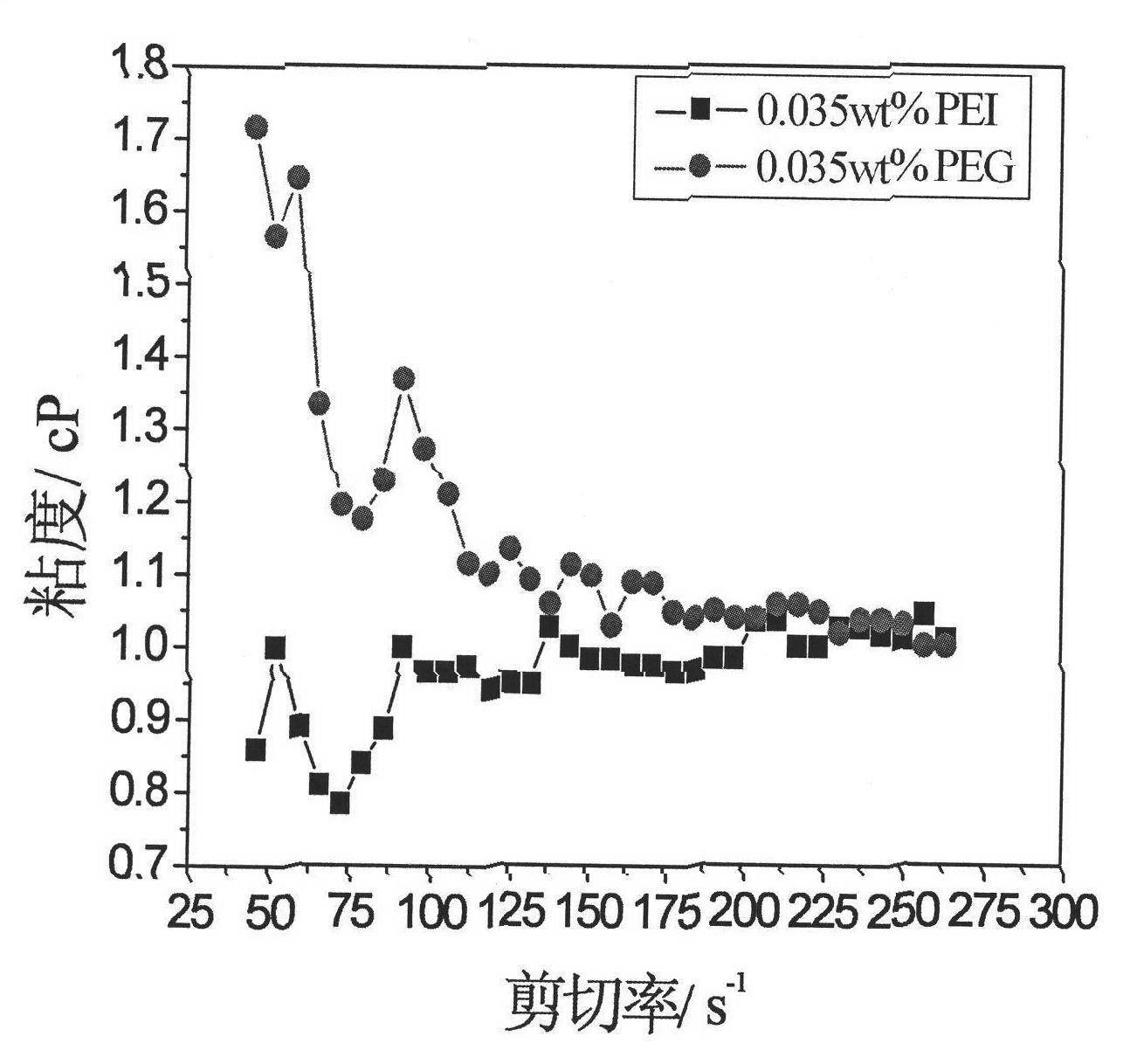

[0020] Example 2: Prepare 0.5075 g of cermet mixed powder according to Table 1, add 20 mL of absolute ethanol, and add 0.0350 wt % of PEI or PEG to the mixed powder respectively. Put the slurry configured in the beaker into an ultrasonic biochemical analyzer to vibrate for 20 minutes, quickly pour it into the adapter of the HB DV-II+Pro rotational viscometer to measure the viscosity of the slurry, and evaluate the dispersion by viscosity measurement. Viscosity The smaller the , the better the dispersibility, and vice versa, the worse the dispersibility.

[0021] figure 2 The rheological curve of the slurry when the mixed powder is dispersed in absolute ethanol under the addition of 0.0350wt% PEI and 0.0350wt% PEG. It can be seen from the figure that under the same amount of addition, the viscosity of the system added with PEI is significantly lower than that of the system added with PEG, and the dispersion effect of PEI is better than that of PEG.

example 3

[0022] Example 3: prepare cermet mixed powder according to the composition ratio in Table 1 and carry out ball milling, use absolute ethanol as the ball milling medium, add 1.1628wt% PEI, adjust the pH to 6.5 with formic acid, the ball-to-material ratio is 5:1, and the rotating speed is 160r / min , Milling time 48h. After the slurry is dried and ground, it is pressed into shape under a pressure of 200 MPa, and then degreased and sintered to form a final product.

[0023] Table 3 lists the green density of PEI with and without dispersant. Since PEI can act as a lubricant in the pressing process, adding PEI can effectively increase the density of the sample, and the increase is about 2.9%.

[0024] Table 3 Density of Ti(C,N)-based cermet compacts

[0025]

[0026] Table 4 lists the flexural strength of Ti(C,N)-based cermet samples prepared with and without dispersant PEI. The determination of flexural strength follows GB 3851-83. After adding PEI, the powder dispersibility...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com