Preparation and application of K3Al2(PO4)3 non-linear optical crystal

A technology of nonlinear optics and crystals, applied in the field of preparation of nonlinear optics crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

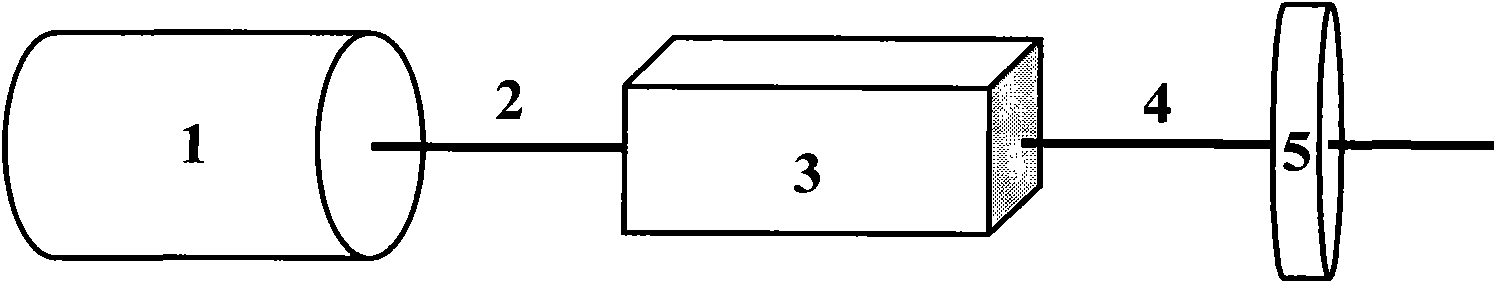

Image

Examples

Embodiment 1

[0035] Embodiment 1. high temperature solid state reaction method prepares powdery K 3 al 2 (PO 4 ) 3 Polycrystalline powder

[0036] According to the reaction formula (2): 3K 2 O+2Al 2 o 3 +6NH 4 h 2 PO 4 = 2K 3 al 2 (PO 4 ) 3 +9H 2 O↑+6NH 3 ↑

[0037] Weigh 12.42gK 2 O, 6.12gAl 2 o 3 and 20.70gNH 4 h 2 PO 4 (K 2 O:Al 2 o 3 : NH 4 h 2 PO 4 = 0.09mol: 0.06mol: 0.18mol), put the weighed raw materials into a mortar, mix and carefully grind them, then put them into a Φ60mm×60mm open platinum crucible, compact them, and put them into a muffle furnace , heat up to 200°C at 30°C / hour, keep the temperature for 10 hours, take it out after cooling, and the sample is loose at this time; take out the sample and grind it again, then put it in a crucible for compaction, in the muffle furnace, at 50°C Heat up to 500°C per hour and sinter for 24 hours. At this time, the sample shrinks into a block; take out the sample and re-grind and mix it, then put it in a cruc...

Embodiment 2

[0038] Embodiment 2: Flux method prepares K 3 al 2 (PO 4 ) 3 Nonlinear Optical Crystals.

[0039] Weigh 55.2 g of K 2 CO 3 , 20.2 g Al 2 o 3 and 92.0 g NH 4 h 2 PO 4 [K 3 al 2 (PO 4 )3 : K 2 O:P 2 o 5 =1mol:0.5mol:0.5mol] After the raw materials are uniformly mixed, put them into an open platinum crucible of Φ80mm×60mm, place them in a muffle furnace, raise the temperature to 700°C at 30°C / hour, keep the temperature constant for 24 hours, and take it out after cooling , put it into a mortar and crush it, and melt it in batches in a Φ60mm×60mm open platinum crucible in a muffle furnace at 1050°C; after cooling, put the crucible into a vertical single crystal growth furnace, and put the Seal the opening on the top of the vertical single crystal growth furnace, leave a small hole at the position corresponding to the top of the vertical single crystal growth furnace and the center of the crucible for the seed rod to enter and exit, and heat up to 1050°C at 50°C / hou...

Embodiment 3

[0040] Embodiment 3: flux method prepares K 3 al 2 (PO 4 ) 3 nonlinear optical crystal

[0041] with synthetic K 3 al 2 (PO 4 ) 3 Polycrystalline powder (the product obtained in Example 1) is raw material, analytically pure K 2 CO 3 and NH 4 h 2 PO 4 As a flux, weigh 47.6 grams of K 3 al 2 (PO 4 ) 3 Powder, 6.9 g K 2 CO 3 , 34.5 g NH 4 h 2 PO 4 [equivalent to K 3 al 2 (PO 4 ) 3 : K 2 O:P 2 o 5 =1mol: 0.5mol: 1.5mol], evenly mixed, melted in batches at 1030°C in a muffle furnace in an open platinum crucible of Φ60mm×60mm; after cooling, put the crucible into a vertical single crystal growth furnace, Seal the opening at the top of the furnace with insulating material, leave a small hole at the corresponding position between the top of the furnace and the center of the crucible for the entry and exit of the seed rod, raise the temperature to 1030°C at 80°C / hour, keep the temperature for 24 hours, then set the temperature at 20°C °C / hour to cool down to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com