Preparation method of sapphire doping agent

A dopant, sapphire technology, applied in the directions of diffusion/doping, chemical instruments and methods, crystal growth, etc., can solve the problems of increased density of single crystal sapphire, uneven distribution of impurities, and influence on crystal quality, reaching a wide market and applicability, high purity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preparation method of sapphire dopant:

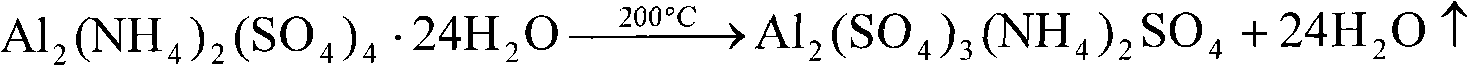

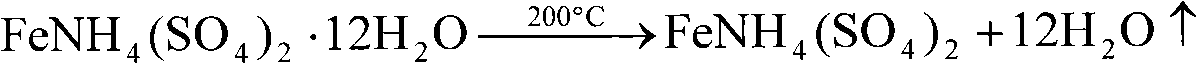

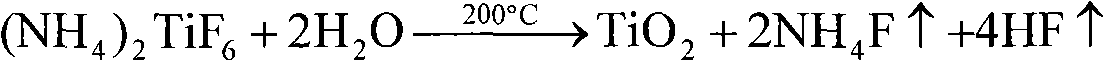

[0020] Add high-purity ferric ammonium sulfate powder and high-purity ammonium fluorotitanate powder into pure water, mix and dissolve to form a solution, the content of ferric ammonium sulfate in the solution is 0.005-0.01g / ml, and the content of ammonium fluorotitanate is 0.0005- 0.001g / ml, then add aluminum ammonium sulfate powder into the solution and mix and stir, the ratio of solution to aluminum ammonium sulfate powder is 10-15ml: 1Kg, then heat to 200°C, keep the temperature for 80-100min for dehydration reaction, and heat up to 900°C , constant temperature 110-120min for deamination, desulfurization reaction, and then get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com