Optical fiber temperature/humidity sensor inductive layer and preparation method and application thereof

A technology of humidity sensor and sensing layer, which is applied in the field of sensors, can solve the problems of increasing the difficulty of the process, and achieve the effects of meeting the requirements of sensor detection, obvious economic benefits, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

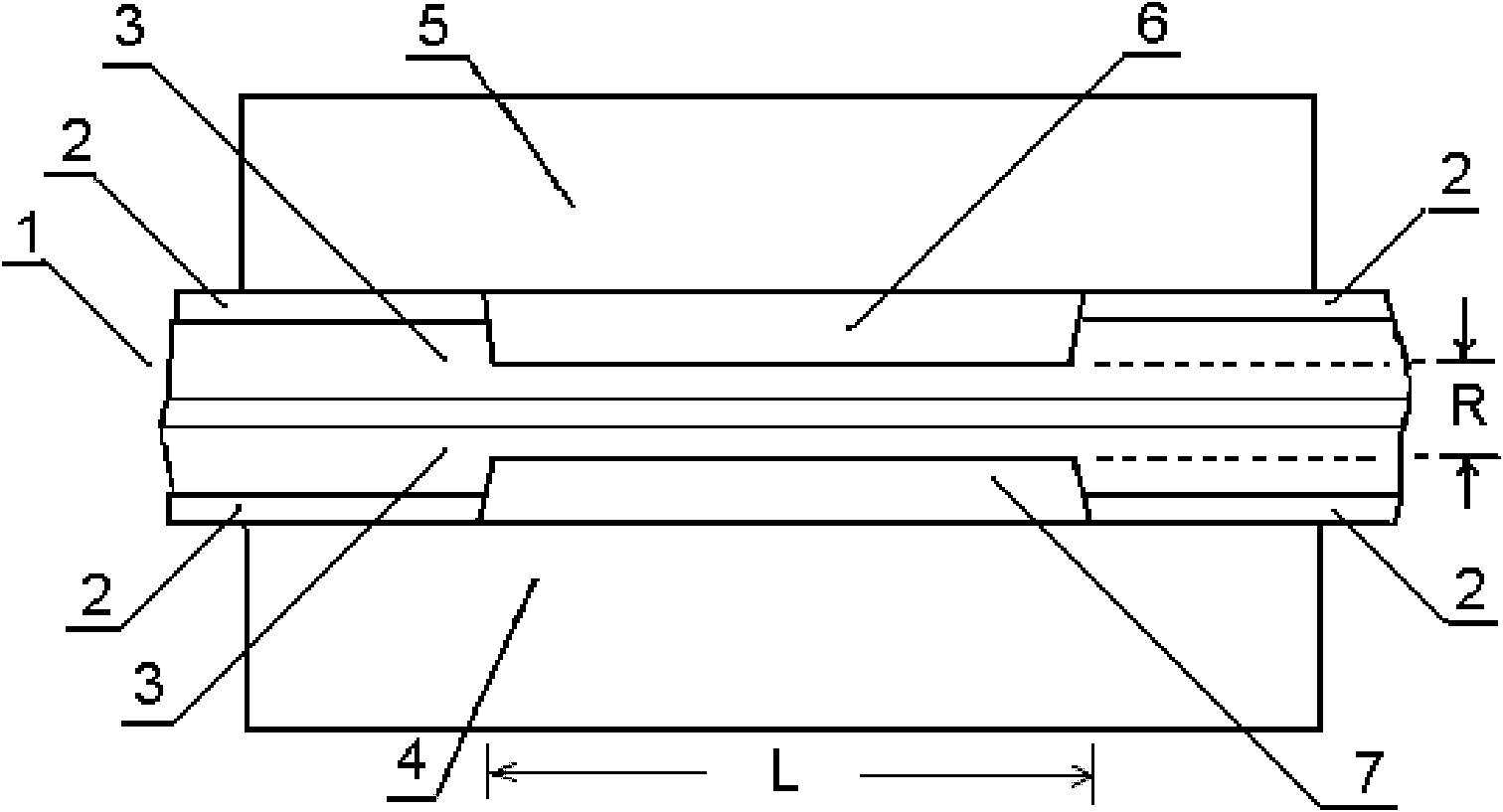

[0033] figure 1 An embodiment of the present invention is shown, and the preparation method of the sensing layer of the optical fiber humidity sensor specifically includes the following steps:

[0034] (1) Form an optical fiber sensing section with a smaller outer diameter on the optical fiber 1, the two ends of the optical fiber sensing section are optical fibers provided with a protective jacket, and the outer diameters of both ends are greater than the outer diameter of the optical fiber sensing section; It is a commercially available step-type optical fiber, the model is Corning SMF-28e bare fiber, the length of the optical fiber sensing section is L as shown in the figure, remove the protective layer 2 on the optical fiber sensing section with optical fiber pliers, and use 5% to 40% hydrogen Fluoric acid corrodes part of the optical fiber cladding 3, and the outer diameter of the remaining cladding is R as shown in the figure;

[0035] (2) The optical fiber sensing secti...

Embodiment 2

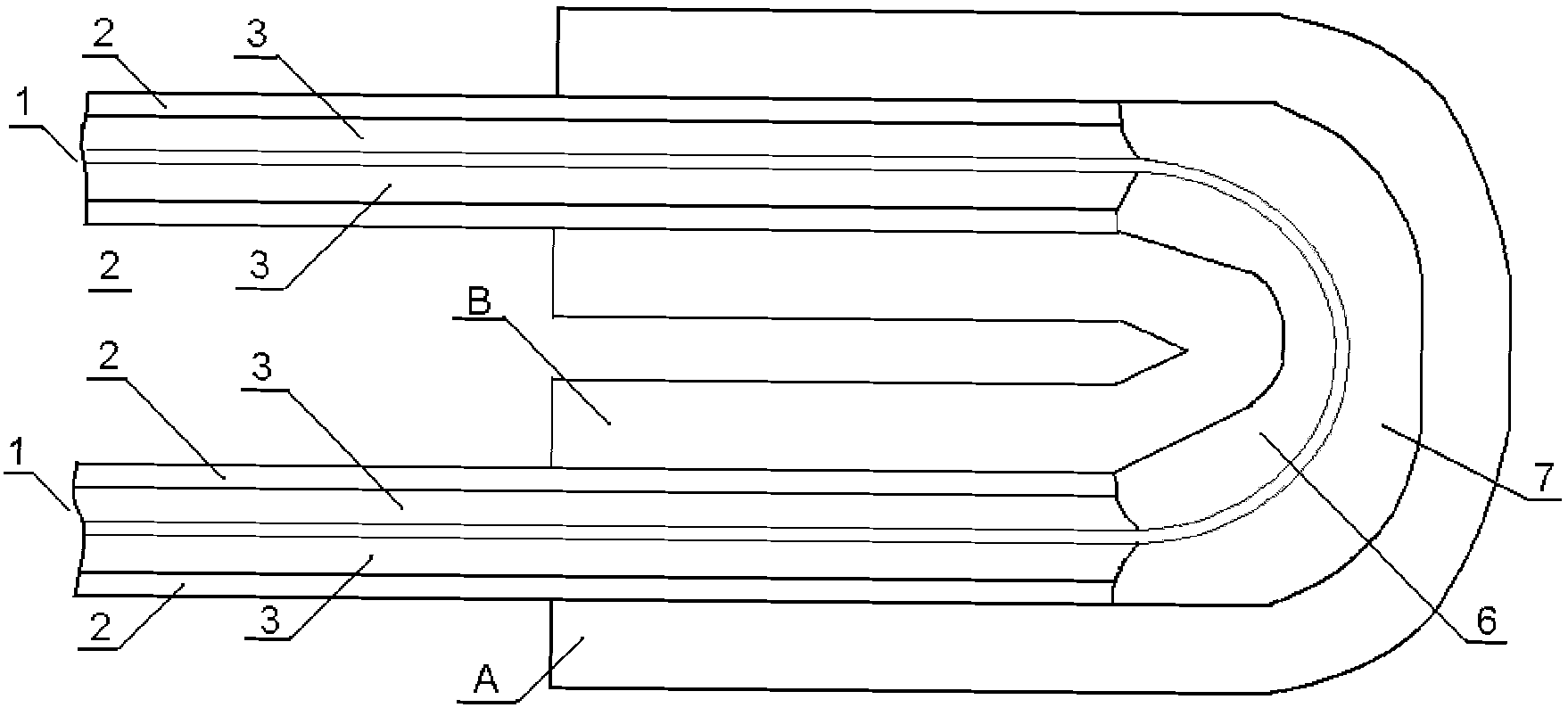

[0041] image 3 Another embodiment of the present invention is shown. The method for preparing the sensing layer of the optical fiber temperature / humidity sensor specifically includes the following steps:

[0042] (1) An optical fiber sensing section with a smaller outer diameter is formed on the optical fiber 1, and the two ends of the optical fiber sensing section are optical fibers provided with a protective coating / protective jacket, and the outer diameters of both ends are larger than the outer diameter of the optical fiber sensing section , the optical fiber sensing section is fixed in a U-shape; the optical fiber is a YOFC Chuangyou multimode bare fiber, and the protective layer 2 on the optical fiber sensing section is removed with fiber optic clamps, and corroded with 5% to 40% hydrofluoric acid Fiber cladding 3;

[0043] (2) Set the U-shaped optical fiber sensing section between two independent U-shaped metal wires, the bending inner diameter of U-shaped metal wire ...

Embodiment 3

[0047] Figure 4 Another embodiment of the present invention is shown. The method for preparing the sensing layer of the optical fiber temperature / humidity sensor specifically includes the following steps:

[0048] (1) Optical fiber 1 uses a commercially available single-mode bare fiber, removes the protective layer 2 on the sensing section L with fiber optic pliers, and fabricates a fiber grating on the sensing section L;

[0049] (2) The fiber grating is placed between two independent plastic fibers C and D, and is also in the middle of the plastic fibers C and D in the axial direction of the optical fiber. The length of the grating is 2cm (1cm at both ends), and the outer diameters of the two independent plastic fibers C and D are larger than the outer diameter of the fiber grating;

[0050] (3) Attach two independent plastic fibers C and D to the optical fiber 1 and fix them together. The specific fixing method can be clamped with a clamp to clamp the support and the prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com