Lithium ion battery surface clad anode material and preparation method thereof

A lithium-ion battery, surface coating technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low voltage platform, unstable structure, poor high temperature performance, etc., and achieve improved cycle performance and safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

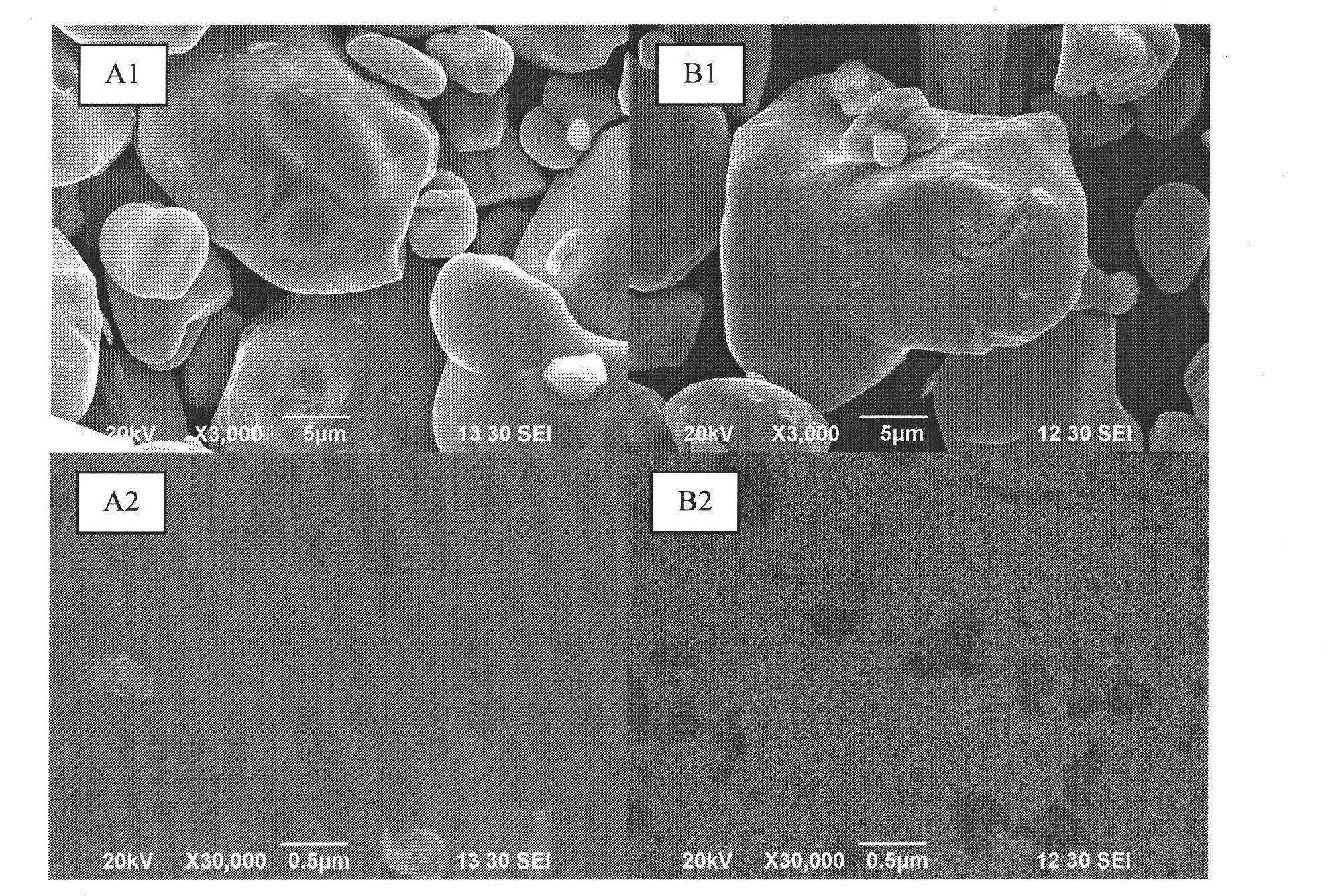

[0044] Weigh 34.5g K 2 ZrF 6 Dissolve in 2kg of deionized water, stir to fully hydrolyze at room temperature; then, add 500g of LiCoO under stirring 2 After stirring, add dropwise 2M ammonia water to adjust the pH of the mixture to 7, and continue to stir for 5 hours; then, stop stirring and filter, wash with deionized water, and dry at 85°C; finally, the dried mixture It is calcined at 1000° C. for 2 hours and slowly cooled to room temperature to obtain a surface-coated positive electrode material with a coating amount of 3%.

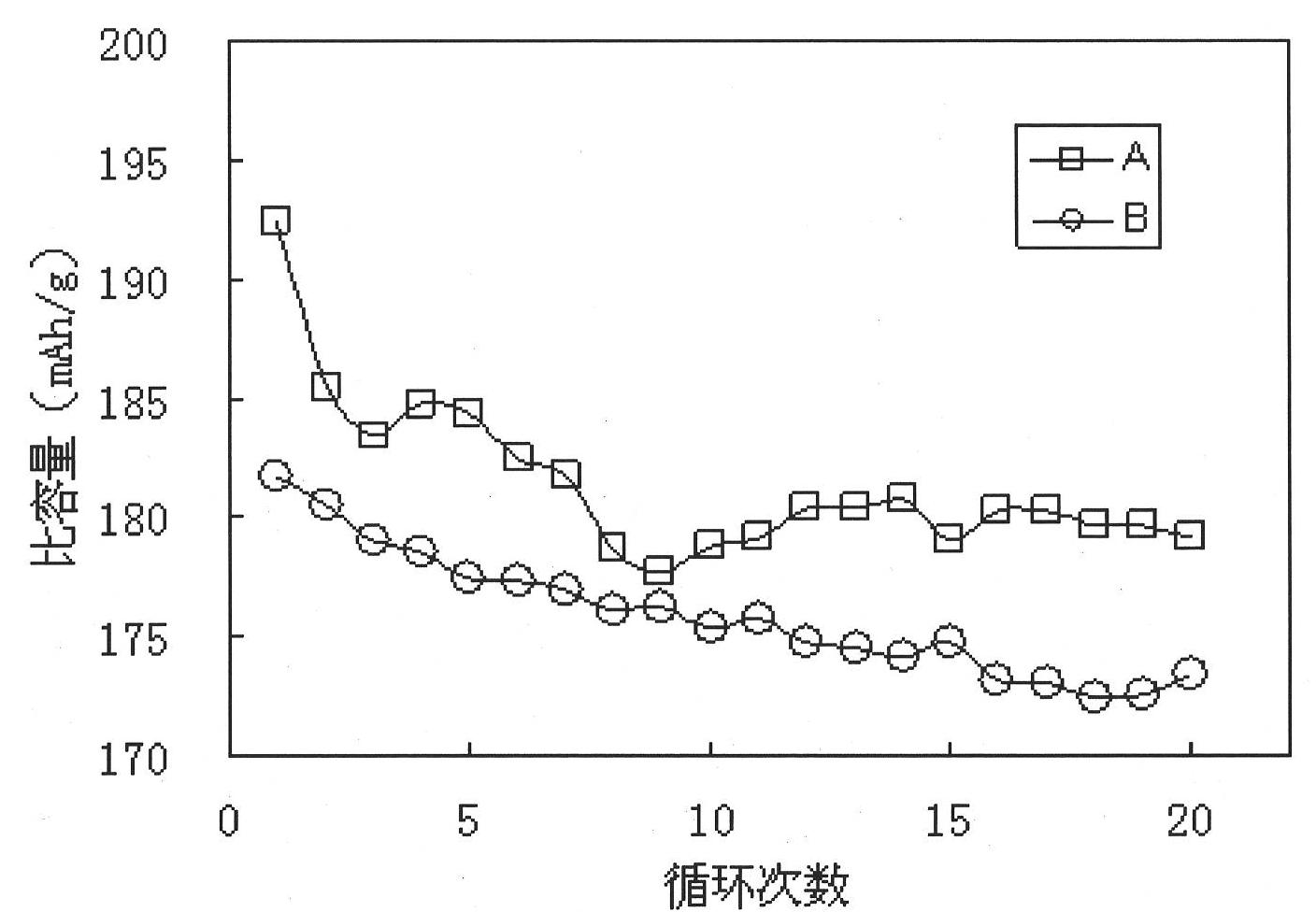

[0045] The surface-coated positive electrode material prepared according to the aforementioned method is uniformly mixed with conductive carbon and polyvinylidene fluoride (PVDF) to prepare a positive electrode slurry, which is coated on the positive electrode current collector to form the positive electrode, and the lithium sheet is used as the negative electrode in the glove box It is composed of button batteries and subjected to electrochemical testing....

example 2

[0047] Weigh 55g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 4kg deionized water, stirred at room temperature to make it fully hydrolyzed; then, 500g LiCoO was added under stirring conditions 2 After stirring, add dropwise 2M ammonia water to adjust the pH value of the mixture to 8, and continue stirring for 5 hours; then, stop stirring and filter, wash with deionized water, and dry at 85°C; finally, the dried mixture It is calcined at 600° C. for 2 hours and slowly cooled to room temperature to obtain a surface-coated positive electrode material with a coating amount of 3%.

[0048] The surface-coated positive electrode material prepared according to the foregoing method is uniformly mixed with conductive carbon and PVDF to prepare a positive electrode slurry, which is coated on the positive electrode current collector to form the positive electrode, and the lithium sheet is used as the negative electrode to form a button cell in a glove box. Conduct an electrochemical test. image 3 Li...

example 3

[0050] Weigh 36g of dimethyl titanate and dissolve it in 500g of ethanol, stir at room temperature to make it fully hydrolyzed; then, add 500g of LiNi under stirring conditions 0.8 Co 0.2 O 2 , Adjust the pH to 11 and stir evenly for 5 hours; then, stop stirring and filter, wash with ethanol, and dry at 90°C; finally, the dried mixture is calcined at 500°C for 5 hours and slowly cooled to room temperature to obtain the coating 3% of the surface is coated with positive electrode material.

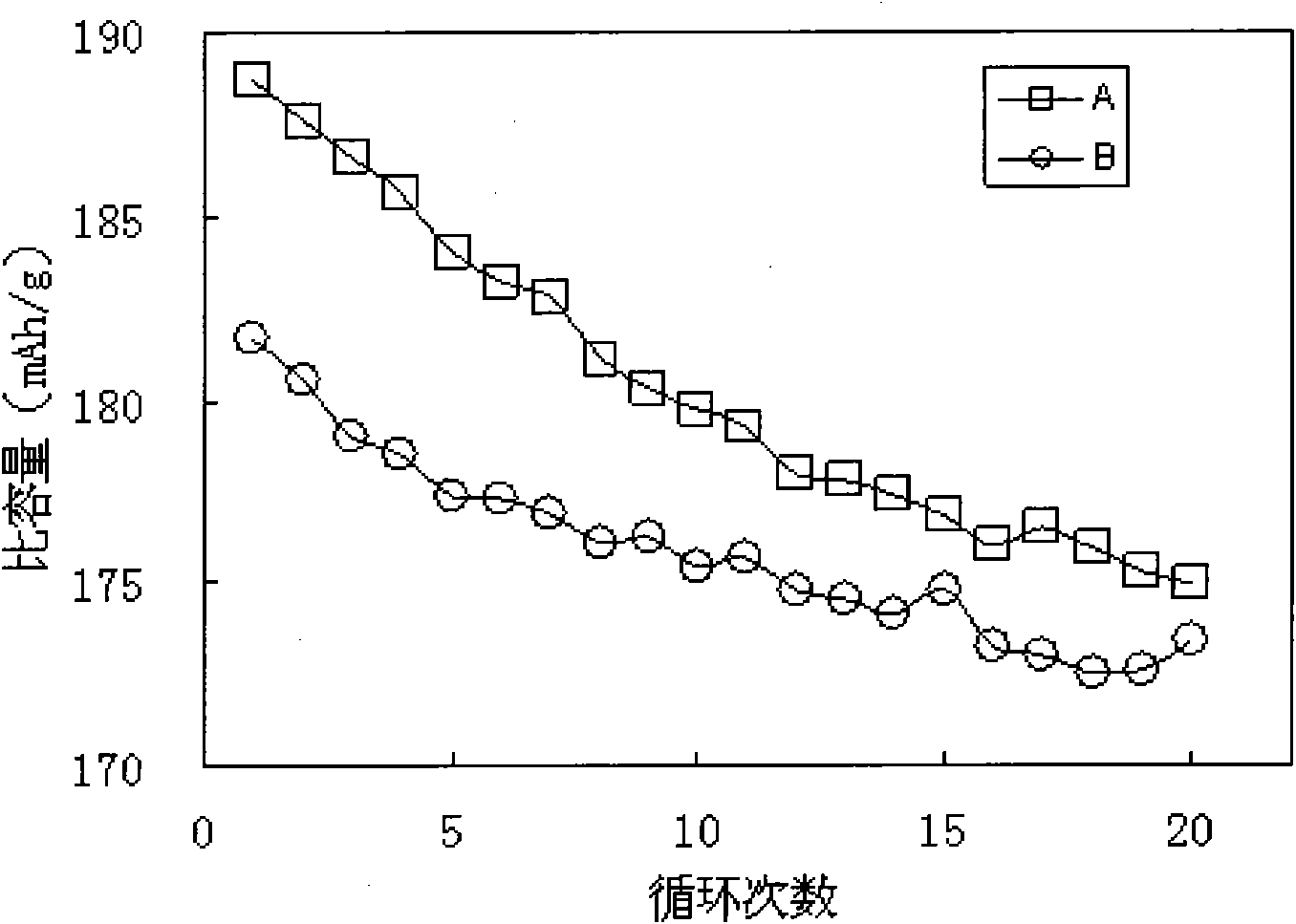

[0051] The surface-coated positive electrode material prepared according to the foregoing method is uniformly mixed with conductive carbon and PVDF to prepare a positive electrode slurry, which is coated on the positive electrode current collector to form the positive electrode, and the lithium sheet is used as the negative electrode to form a button cell in a glove box. Conduct an electrochemical test. Figure 4 LiNi 0.8 Co 0.2 O 2 Coated TiO 2 Before and after, in the range of 3.0-4.3V, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com