Photocatalyst metal ceiling processing method and equipment

A processing method and technology of processing equipment, applied in special surfaces, pretreated surfaces, covering/lining, etc., can solve the problems of the ceiling surface being prone to fog, affecting the aesthetics of products, and troublesome cleaning, etc. Simple process and easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

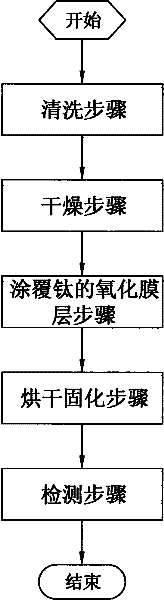

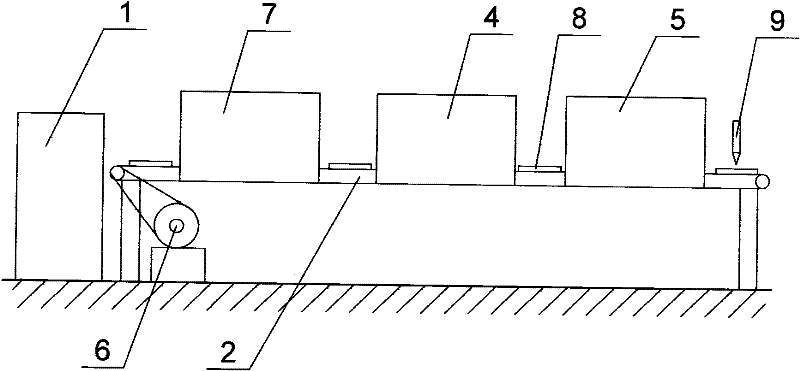

[0043] Such as figure 1 Shown, the photocatalyst metal ceiling processing method of the present embodiment comprises the following steps:

[0044] (a) cleaning step: put the metal ceiling 8 into the ultrasonic cleaning device 1 for cleaning, and remove the dust, oil and impurities on the surface of the metal ceiling 8;

[0045] (b) Drying step: the metal ceiling 8 after cleaning is sent to the drying device 7 through the conveying device 2, and the surface of the metal ceiling 8 is dried;

[0046] (c) Step of coating the oxide film layer of titanium: the metal ceiling 8 after drying is sent into the first automatic spraying device 4 through the conveying device 2, and water-soluble titanium dioxide is sprayed on the surface of the metal ceiling 8 to form Titanium oxide film layer 92;

[0047] (d) drying and curing step: the metal ceiling 8 coated with the titanium oxide film layer 92 is sent to the infrared baking device 5 through the conveying device 2, and the titanium oxi...

Embodiment 2

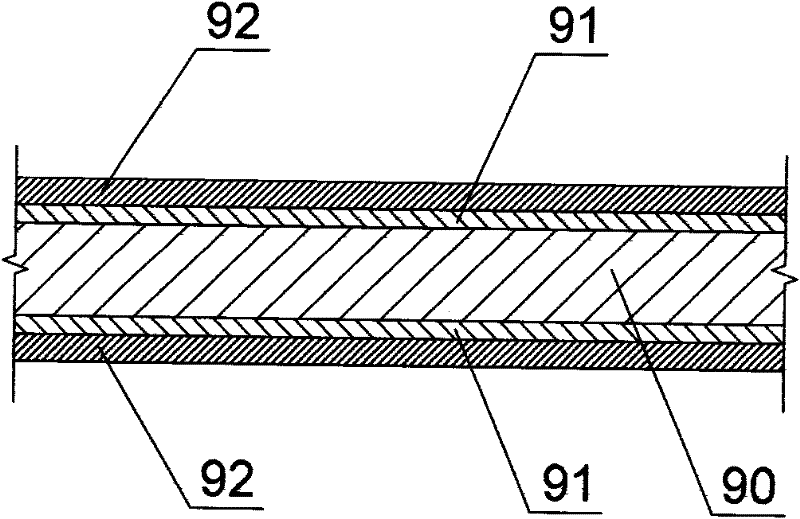

[0052] Such as Figure 4 Shown, the photocatalyst metal ceiling processing method of the present embodiment comprises the following steps:

[0053] (a) cleaning step: put the metal ceiling 8 into the ultrasonic cleaning device 1 for cleaning, and remove the dust, oil and impurities on the surface of the metal ceiling 8;

[0054] (b) Drying step: the metal ceiling 8 after cleaning is sent to the drying device 7 through the conveying device 2, and the surface of the metal ceiling 8 is dried;

[0055] (b1) Step of coating the isolation layer: the metal ceiling 8 is sent into the second automatic spraying device 3 through the conveying device 2, and the surface of the metal ceiling 8 is coated with an inorganic isolation layer 91;

[0056] (c) step of coating titanium oxide film layer: the metal ceiling 8 after drying is sent into the first automatic spraying device 4 through the conveying device 2, and water-soluble titanium dioxide is sprayed on the surface of the inorganic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com