Environmental protection type self-radiation nano ecological paint and preparation method thereof

A self-heating, environmentally friendly technology, applied in the coating and other directions, can solve the problems of low heat dissipation performance, adverse effects on the environment and the body, etc., to achieve the effect of improving self-heating performance, enhancing heat transfer characteristics, and reducing environmental pollution factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

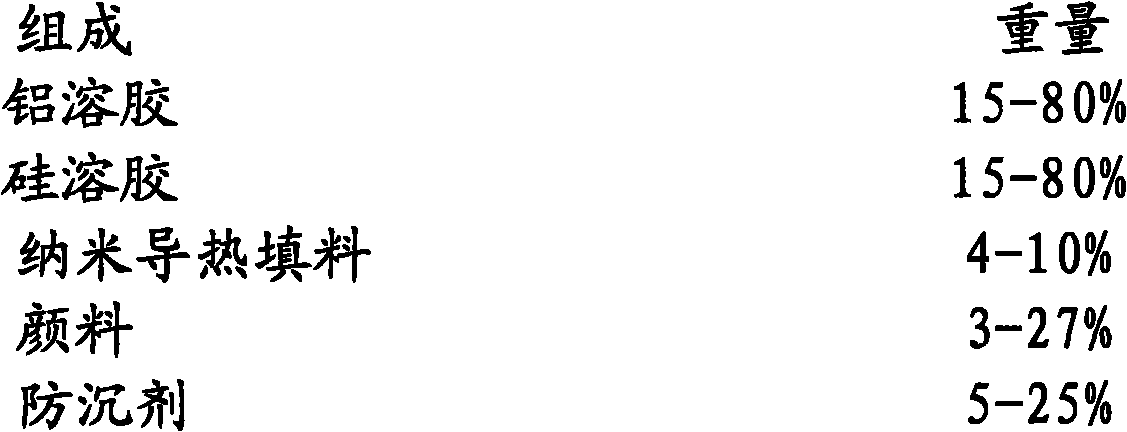

[0024] The environment-friendly self-heating nano-ecological coating of the present invention can be formed according to the following formula:

[0025]

[0026] These components together amount to 1000kg.

[0027] The aluminum sol is a water-dispersed nanoscale alumina, and its particle size can be selected as 15nm.

[0028] The silica sol is a water-dispersed nano-scale silica with a particle size of 20 nm.

[0029] The nano thermal conductive filler is a composite of 20kg carbon nanotubes and 50kg nano-cobalt oxide. The carbon nanotubes are single-wall carbon nanotubes with a diameter of 30-50nm and a length of 5-10μm. is 20nm.

[0030] Among them, the pigment can be selected as copper chrome black, which has excellent chemical resistance, outdoor weather resistance, thermal stability, light resistance, and has no permeability and no migration.

[0031] Among them, the anti-settling agent can be selected from sodium-based bentonite in inorganic bentonite, and this com...

specific Embodiment 2

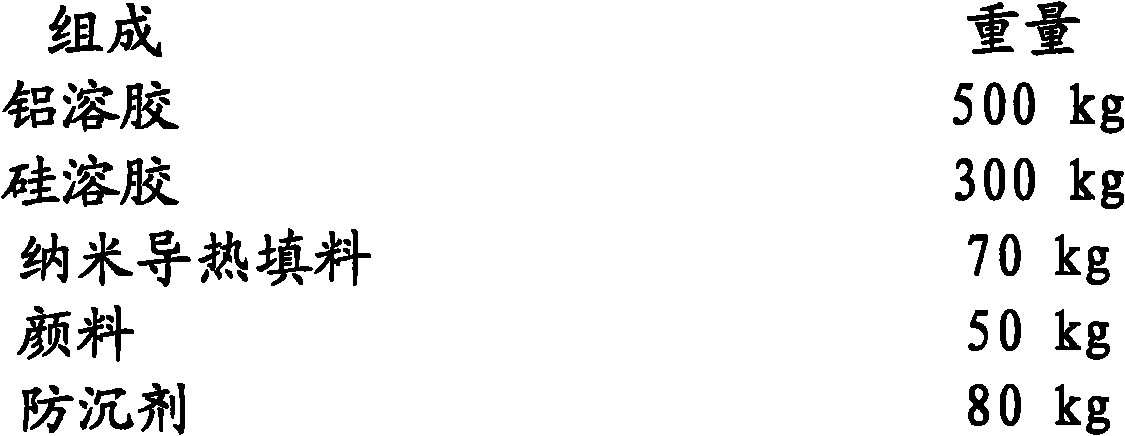

[0032] The environment-friendly self-heating nano-ecological coating of the present invention can be formed according to the following formula:

[0033]

[0034] These components together amount to 1000kg.

[0035] The aluminum sol is a water-dispersed nanoscale alumina, and its particle size can be selected as 25nm.

[0036] The silica sol is a water-dispersed nano-scale silica with a particle size of 15 nm.

[0037] The nano thermally conductive filler is a composite of 30kg carbon nanotubes and 70kg nano zirconia. is 20nm.

[0038] Among them, the pigment can be selected as titanium dioxide, which has strong covering power, uniform and fine particles, easy to disperse and stable performance.

[0039] Among them, the anti-settling agent, etc., can be selected from the lithium-based bentonite in the inorganic bentonite, which has extremely high physical and chemical properties and dispersibility, and plays an important role in the molding of coatings.

specific Embodiment 3

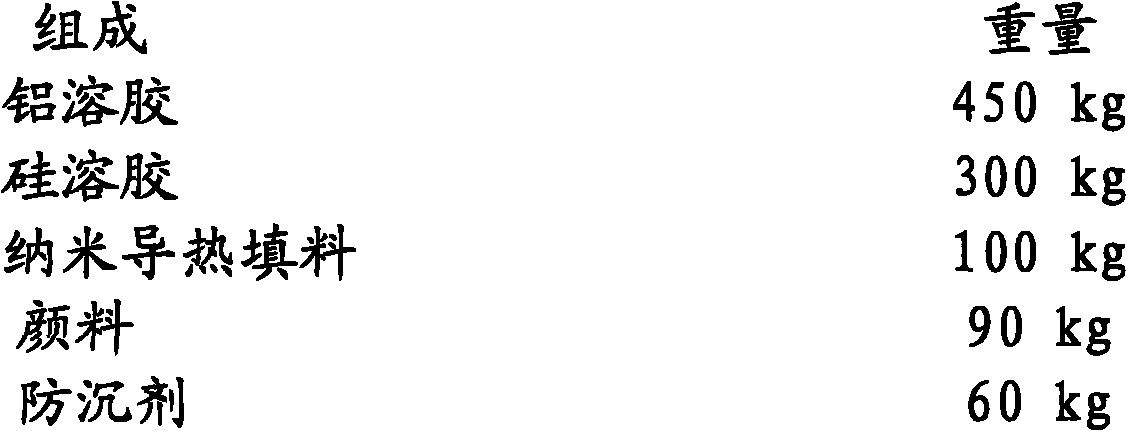

[0040] The environment-friendly self-heating nano-ecological coating of the present invention can be formed according to the following formula:

[0041]

[0042] These components together amount to 1000kg.

[0043] The aluminum sol is a water-dispersed nanoscale alumina, and its particle size can be selected as 35nm.

[0044] The silica sol is a water-dispersed nano-scale silica with a particle size of 25 nm.

[0045] The nano thermally conductive filler is a composite of 40kg carbon nanotubes, 30kg nanocobalt oxide and 20kg nanozirconium oxide. The particle size of grade cobalt oxide and zirconium oxide is 20 nm.

[0046] Among them, the pigment, optional cobalt blue, has excellent hiding power, color transparency and high tinting strength, thermal stability, light fastness, and high light reflectivity.

[0047] Among them, the anti-settling agent can be selected from calcium-based bentonite in inorganic bentonite, which can enhance the water resistance of the coating, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com