Method for preparing continuous polymerization directly-spun cation-dyeable high-shrinkage polyester staple fibers

A polyester staple fiber, cationic technology, applied in the direction of melt spinning, single-component copolyester rayon, melting of filament raw materials, etc., can solve the fluctuation of indicators such as intrinsic quality and viscosity of products that affect processing and spinning performance Larger, product performance differences and other problems, to achieve the effects of excellent spinning performance, stable product quality, and stable shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

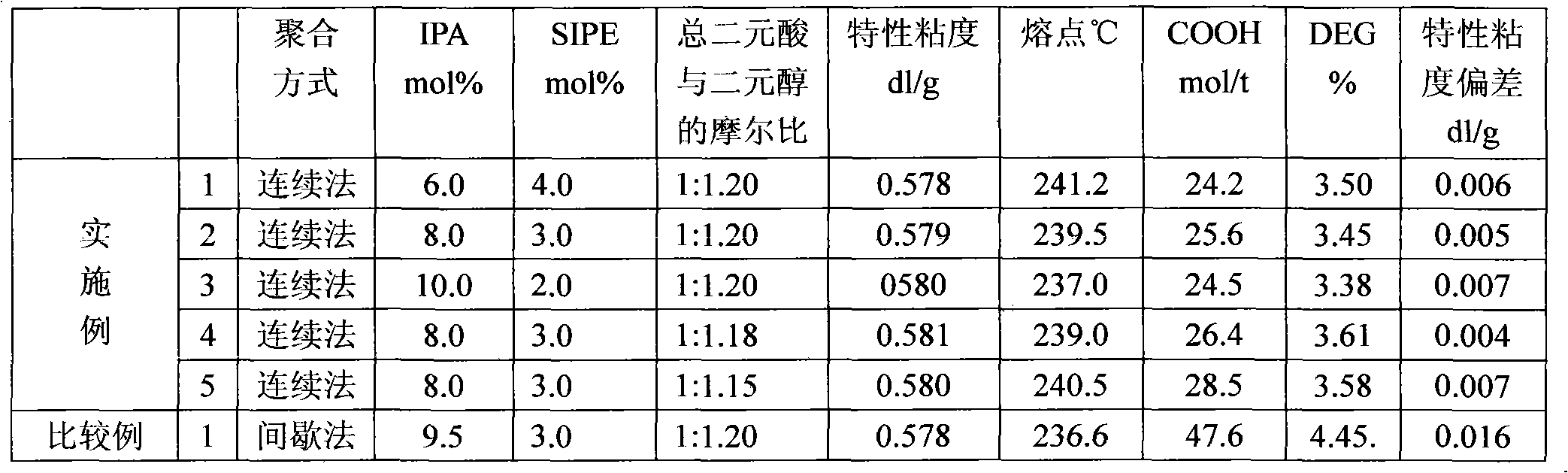

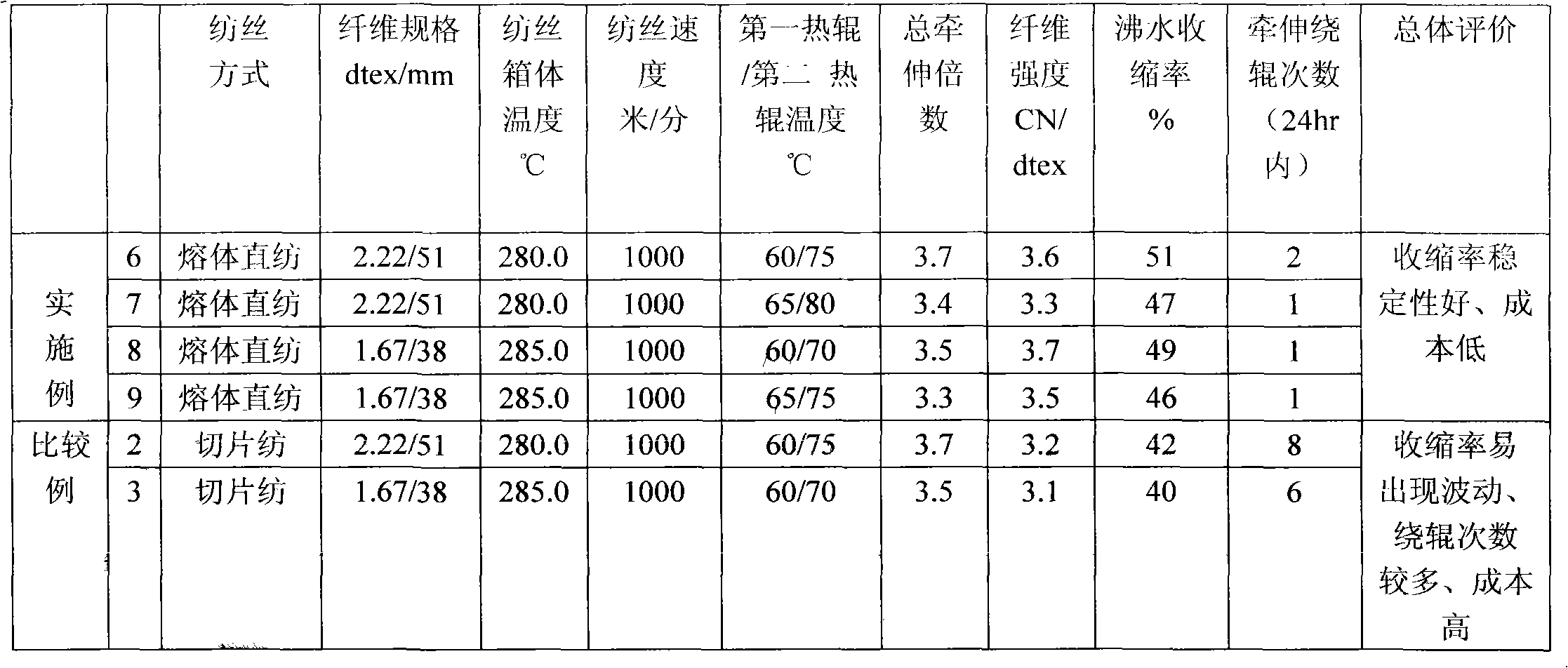

Embodiment 1

[0019] The preparation technology of modified copolyester melt: set the production capacity of 6000kg / hr on the continuous polyester equipment, PTA, IPA and EG monomer account for total dibasic acid (PTA, IPA and SIPE summation) by IPA The mole percentage is 6.0, the total dibasic acid (PTA, IPA and SIPE sum) and glycol (EG) are added to the slurry tank at a molar ratio of 1:1.20, and 450PPM (the weight percentage of the total production capacity) is added to the beating tank at the same time ) polycondensation catalyst ethylene glycol antimony, the above slurry is continuously and stably transported to the esterification-I reactor, the esterification-I pressure is controlled to be 0.12MPa, the temperature is 258.0°C, and the material level is 60.0%. The esterification-I material is sent to Put in the esterification-II reactor, control esterification-II reactor temperature 255 ℃, material level 60.0%, residence time 50 minutes, continuously add simultaneously and account for th...

Embodiment 2

[0021] The method of this embodiment is basically the same as in Example 1, except that the addition of IPA is 8.0%, the temperature of the esterification-I reactor is 259.0°C, the temperature of the esterification-II reactor is 258°C, and the addition of SIPE is 3.0%, then the prepolymer is pumped to the polycondensation section, and the modified copolyester is prepared according to the conventional polycondensation process. (See Table 1 for the results)

Embodiment 3

[0023]The method of this embodiment is basically the same as in Example 1, except that the addition of IPA is 10.0%, the temperature of the esterification-I reactor is 260.0°C, the temperature of the esterification-II reactor is 260°C, and the addition of SIPE is 2.0%, then the prepolymer is pumped to the polycondensation section, and the modified copolyester is prepared according to the conventional polycondensation process. (See Table 1 for the results)

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com