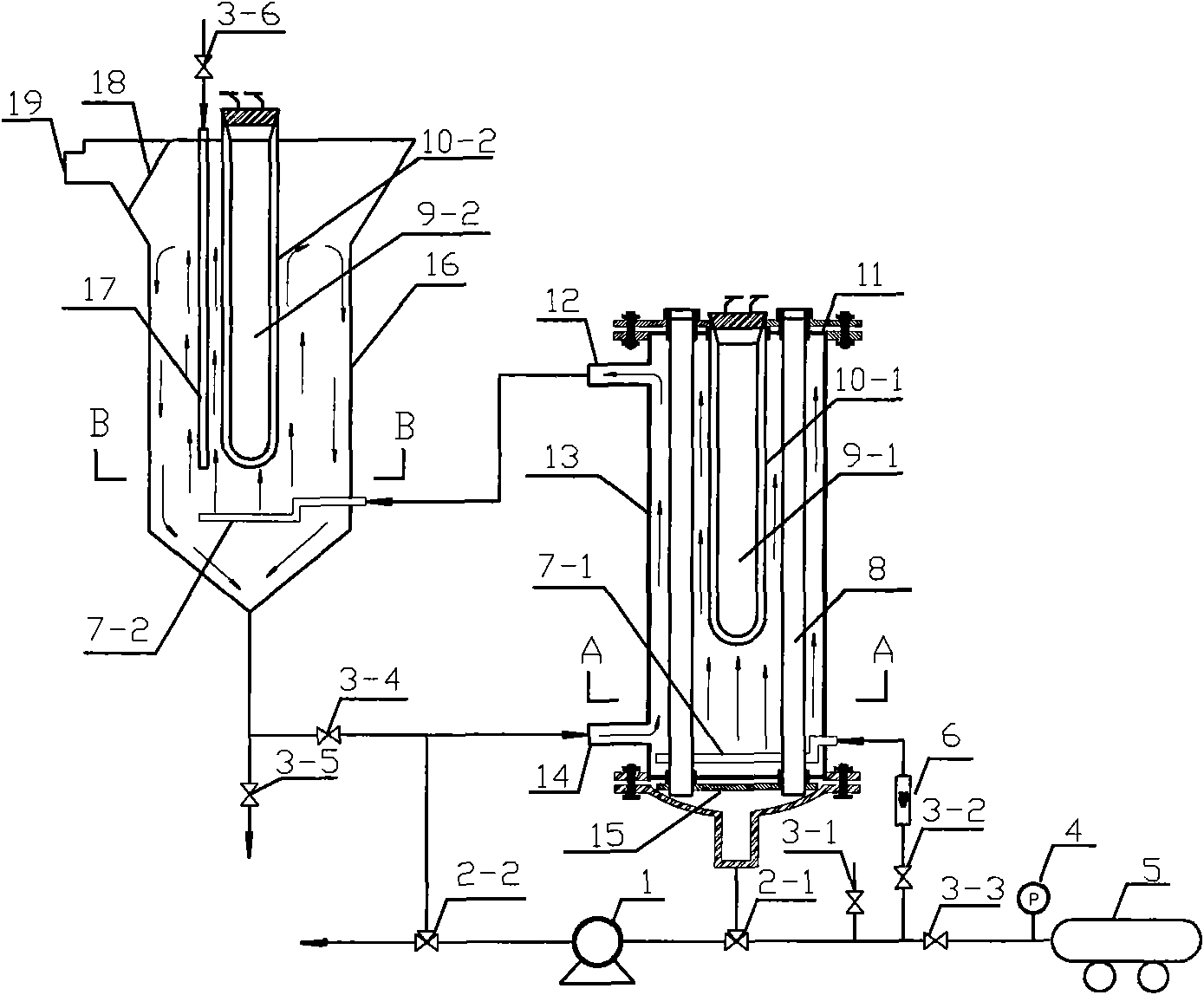

Titanium dioxide precoated dynamic membrane photocatalytic water treatment device

A technology for membrane photocatalytic water and titanium dioxide, which is applied in the fields of oxidized water/sewage treatment, light water/sewage treatment, energy and waste water treatment, etc. effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

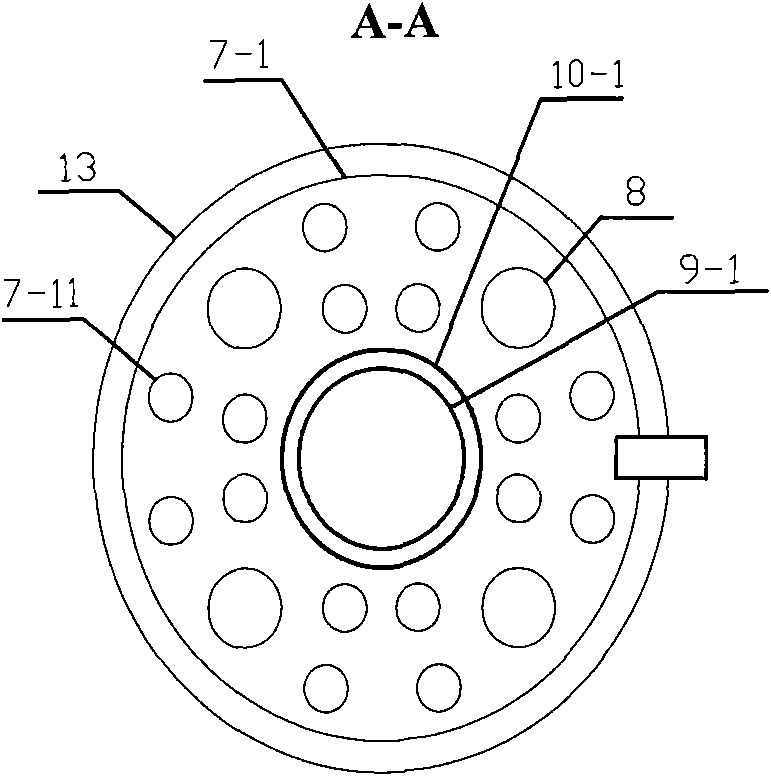

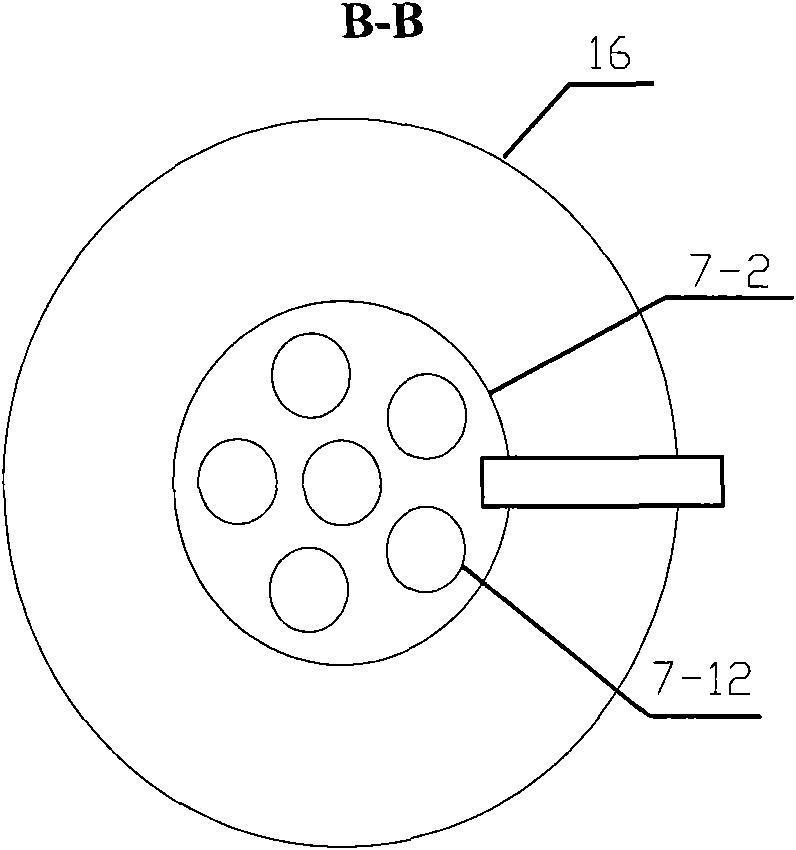

Embodiment 1

[0021] Utilize above-mentioned device to process methyl orange waste water, waste water concentration is 0.8g / l, and pH value is 4.2, adopts 20-100W high-pressure mercury lamp, and the effective reaction volume of two reactors in the device is 5-8 liter, adds 6 wherein Anatase TiO 2 ,TiO 2 The average particle size is 0.2 μm. The ceramic membrane material used is Al 2 o 3 , 3 ceramic membrane tubes, the average pore diameter is 0.1μm, the length is 30cm, the outer diameter is 13mm, the inner diameter is 9mm, the reaction temperature is 25-30°C, the suction negative pressure is stable within the range of 0.06-0.08MPa, and the air intake The gas velocity (corrected) is stable at 15-30L / min, the gas recoil pressure is 0.4MPa, and the gas recoil time is 8s. Under the above conditions, the pre-coated dynamic membrane is prepared first, then the methyl orange wastewater is treated, and finally the membrane is cleaned and regenerated to complete a cycle of operation. Monitoring ...

Embodiment 2

[0023] Utilize above-mentioned device to process methyl orange waste water, waste water concentration is 0.9g / l, and pH value is 4.3, adopts 20-100W high-pressure mercury lamp, and the effective reaction volume of two reactors in the device is 5-8 liters, adds 7 wherein Anatase TiO 2 ,TiO 2 The average particle size is 0.2 μm. The ceramic membrane material used is Al 2 o 3 , 4 ceramic membrane tubes, the average pore diameter is 0.1μm, the length is 30cm, the outer diameter is 13mm, the inner diameter is 9mm, the reaction temperature is 25-30°C, the suction negative pressure is stable within the range of 0.06-0.08MPa, and the air intake The gas velocity (corrected) is stable at 15-30L / min, the gas recoil pressure is 0.4MPa, and the gas recoil time is 8s. Under the above conditions, the pre-coated dynamic membrane is prepared first, then the methyl orange wastewater is treated, and finally the membrane is cleaned and regenerated to complete a cycle of operation. Monitoring...

Embodiment 3

[0025] Utilize above-mentioned device to process methyl orange waste water, waste water concentration is 0.7g / l, and pH value is 4.1, adopts 20-100W high-pressure mercury lamp, and the effective reaction volume of two reactors in the device is 5-8 liter, adds 5 wherein Anatase TiO 2 ,TiO 2 The average particle size is 0.2 μm. The ceramic membrane material used is Al 2 o 3 , 2 ceramic membrane tubes, the average pore diameter is 0.1μm, the length is 30cm, the outer diameter is 13mm, the inner diameter is 9mm, the reaction temperature is 25-30°C, the suction negative pressure is stable within the range of 0.06-0.08MPa, and the air intake The gas velocity (corrected) is stable at 15-30L / min, the gas recoil pressure is 0.4MPa, and the gas recoil time is 8s. Under the above conditions, the pre-coated dynamic membrane is prepared first, then the methyl orange wastewater is treated, and finally the membrane is cleaned and regenerated to complete a cycle of operation. Monitoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com