Batch immersion bioreactor

A technology of bioreactor and bioreactor container, which is applied in biochemical instruments, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of labor-consuming, high repair and maintenance costs, high production costs, etc., to achieve Adjust the effect of simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

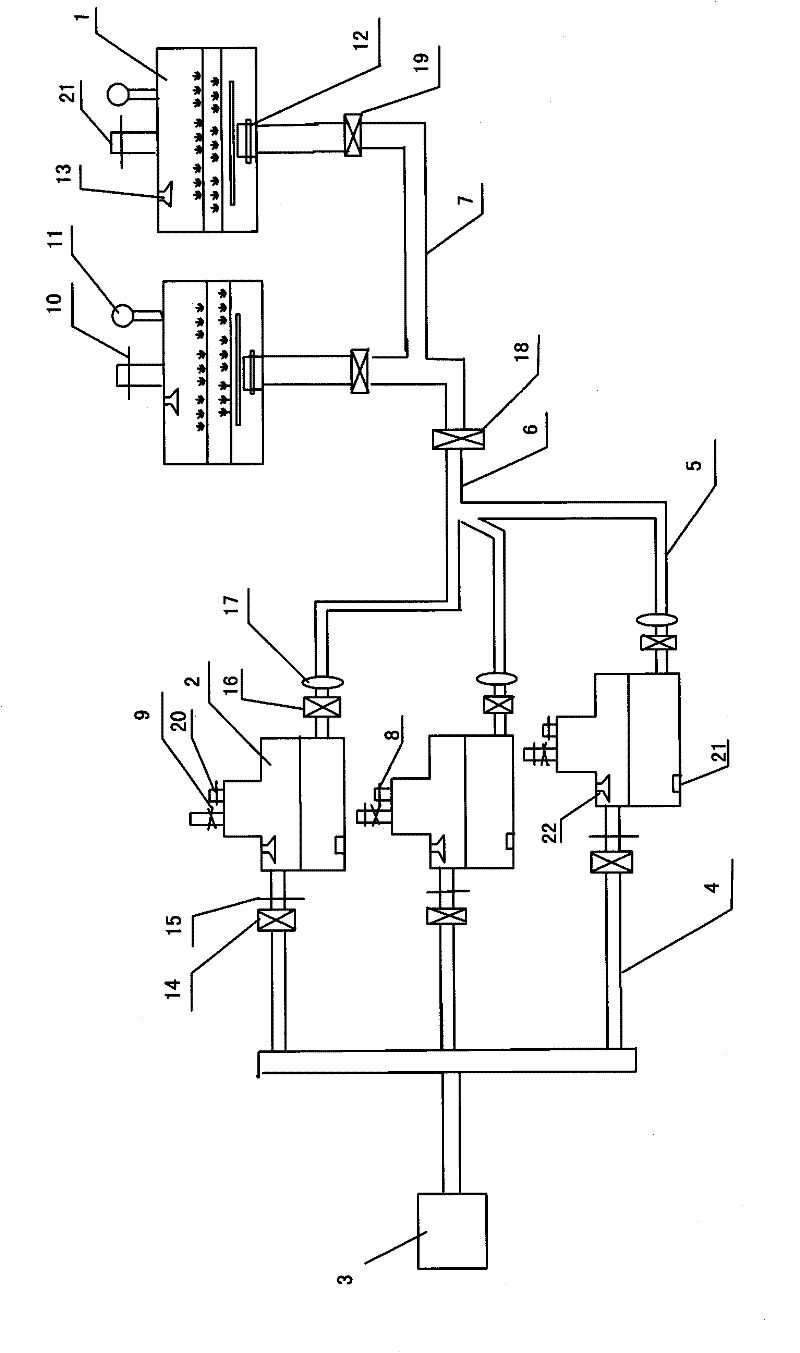

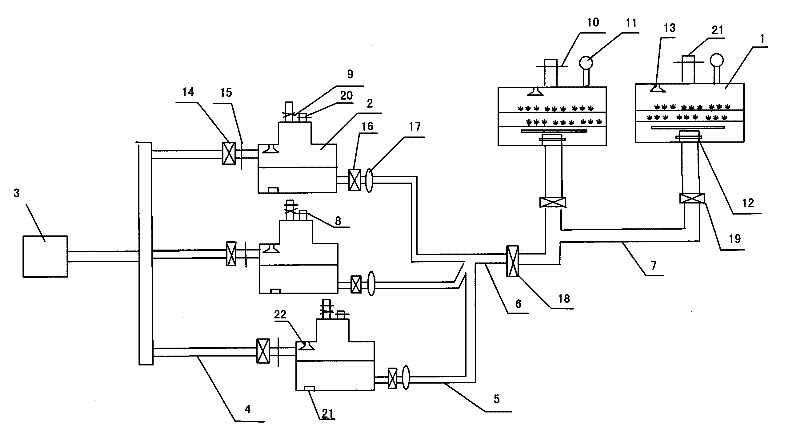

[0018] Such as figure 1 As shown, a kind of intermittent flooding bioreactor mainly includes two bioreactors 1, three nutrient storage containers 2 and an air pump 3, and the upper part of the nutrient storage container 2 is provided with a one-way air valve 9 and a liquid inlet 20, Wherein the liquid inlet port 20 is provided with a first air filter 8, the nutrition storage container 2 is provided with an air inlet branch pipeline 4 and a liquid outlet branch pipeline 5, the upper part of the nutrition storage container is provided with an ultraviolet disinfection lamp 22, and the bottom of the nutrition storage container is provided with There is an ultrasonic generator 21, the inlet branch pipeline 4 is connected to the air pump 3, and the liquid outlet branch pipeline 5 converges at one place to form a main pipeline 6. The main pipeline 6 is provided with a plurality of pipelines 7, and the pipeline 7 is connected to the bioreactor 1, and the bioreactor The horizontal posi...

Embodiment 2

[0022] It is the same as embodiment 1, the difference is that it includes three bioreactors 1 and four nutrient storage containers 2, and the ultrasonic generator 21 provided at the bottom of the nutrient storage containers is omitted.

Embodiment 3

[0024] It is the same as embodiment 1, and the difference is that it includes three bioreactors 1 and five nutrient storage containers 2, and the upper part of the nutrient storage containers is omitted to be provided with an ultraviolet disinfection lamp 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com