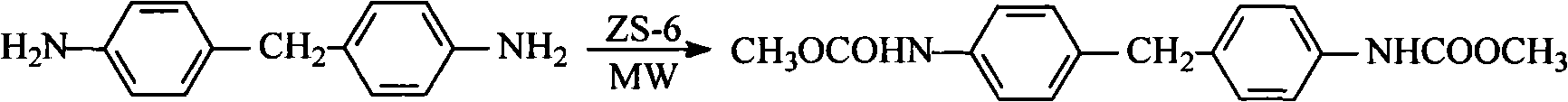

Method for auxiliary synthesis of 4,4'-diphenyl methane diamino acid methyl ester by microwave

A technology of methyl dicarbamate and diphenylmethane, which is applied in the field of ester synthesis, can solve the problems of long process reaction time, etc., and achieve the effects of simplifying the post-processing process, reducing production costs, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment 1: In this embodiment, the microwave-assisted synthesis of methyl 4,4'-diphenylmethane dicarbamate has the following steps: 1. Combine 4,4'-diaminodiphenylmethane and carbonic acid in a microwave reactor. The methyl ester is mixed in a weight ratio of 1:5-20, and then ZS-6 catalyst is added to obtain a mixture; 2. The mixture obtained in step 1 is placed in a microwave reactor with a power of 60W~250W and a temperature of 150℃~200℃ React for 0.5-10 minutes, then cool to room temperature, filter, separate, and recrystallize to obtain methyl 4,4'-diphenylmethane dicarbamate; wherein the amount of ZS-6 catalyst added in step 1 is 4,4 '-Diaminodiphenylmethane 0.1% to 5% of the mass; the ZS-6 catalyst described in step 1 is composed of 50% to 80% zinc acetate, 10% to 40% zinc isooctyl dimercaptoacetate and 5 %~10% triethylbenzylammonium bromide composition.

[0010] In this embodiment, the conversion rate of 4,4'-diaminodiphenylmethane can reach 89.3%-99.6%...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and the first embodiment is that the particle size of the ZS-6 catalyst in step one is 80 mesh to 100 mesh. Others are the same as the first embodiment.

[0012] In this embodiment, the conversion rate of 4,4'-diaminodiphenylmethane can reach 89.3%-99.6%, and the yield of methyl 4,4'-diphenylmethanedicarbamate can reach 94.7%-98.1%.

specific Embodiment approach 3

[0013] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the weight ratio of 4,4'-diaminodiphenylmethane to dimethyl carbonate in step one is 1:10. Others are the same as the first or second embodiment.

[0014] In this embodiment, the conversion rate of 4,4'-diaminodiphenylmethane can reach 89.3%-99.6%, and the yield of methyl 4,4'-diphenylmethanedicarbamate can reach 94.7%-98.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com