Production process of ultrathick insulating paperboard

A technology for insulating cardboard and production process, applied in papermaking, fiberboard, papermaking and other directions, can solve the problems of affecting withstand voltage performance, complex processing methods, low production efficiency, etc., to improve electrical insulation performance, reduce secondary pollution, and oil absorption. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

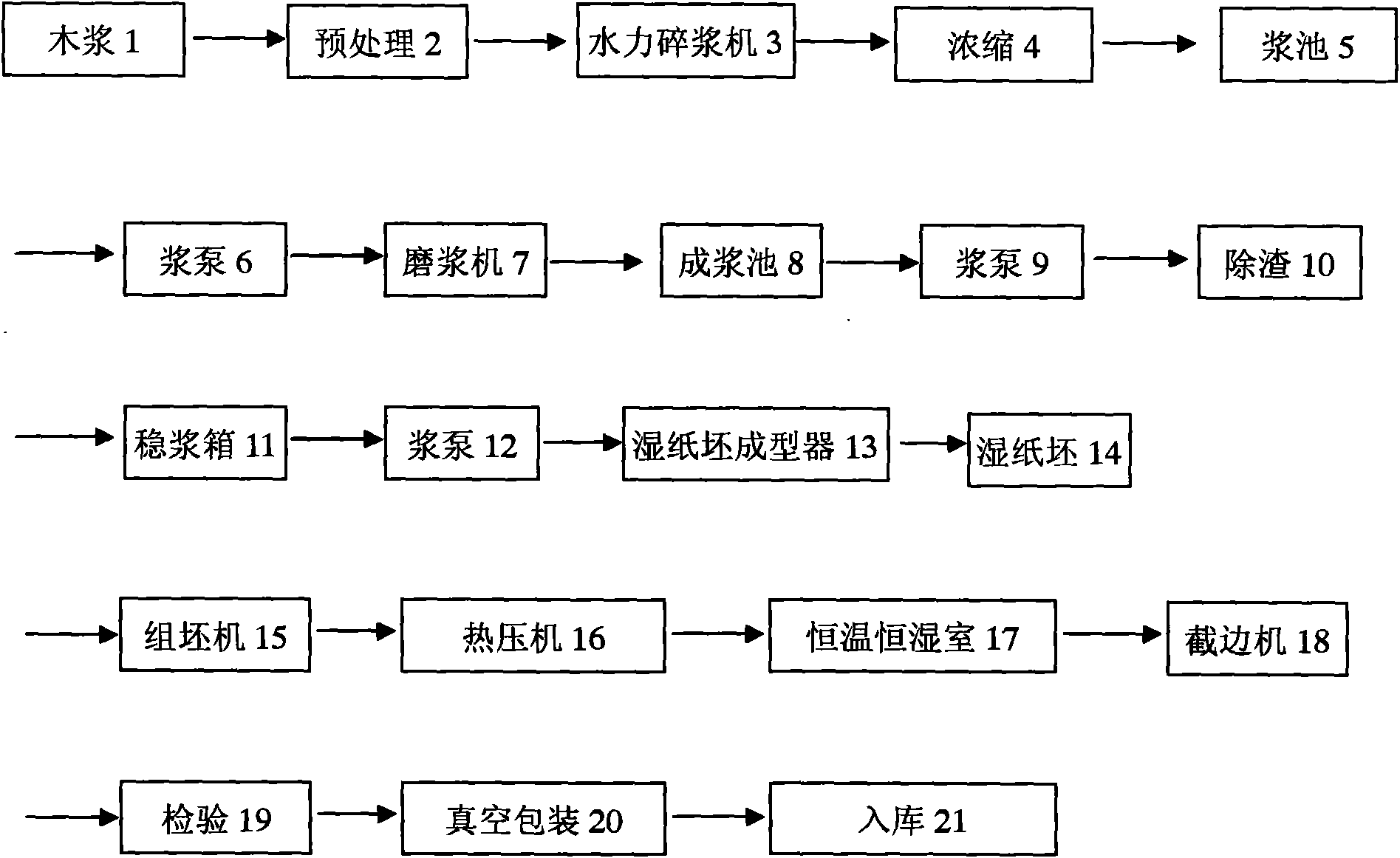

Image

Examples

Embodiment Construction

[0011] Embodiment 1 and 2, the parameter of embodiment 2 is the data in brackets.

[0012] The wood pulp 1 is purified and pretreated 2, then passed through the hydraulic pulper 3, and the crushed pulp is concentrated 3 to a concentration of 4.2 (4.8)% and enters the pulp tank 5, and the pulp is sent to the pulp refiner 7 by the pulp pump 6. Pulp, the pulp has a beating degree of 30 (34) ° SR, a wet weight of 11 (15) g, enters the pulp tank 8, and uses a pulp pump 9 to send the pulp into the high-efficiency low-consistency slag remover 10 and then enters the pulp stabilization box 11 , the pulp pump 12 sends the slurry into the wet paper base former 13, and the wet paper base prepared is sent into the base forming machine 14 for dehydration. When the moisture reaches 40 (50)%, the wet paper base is taken out and sent into the hot press 16 for drying. The humidity is 120 (130) ℃, the drying time depends on the thickness, when the water content of the cardboard is 4 (6)%, take o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com