Chemical corrosion detection method of hot rolling strip steel scale structure

A technology of hot-rolled steel strip and iron scale, applied in the preparation of test samples, measuring devices, scientific instruments, etc., can solve the problems of inaccurate X-ray diffraction results, application limitations, and X-ray impenetrability, etc. The effect of high equipment requirements, wide applicability, and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

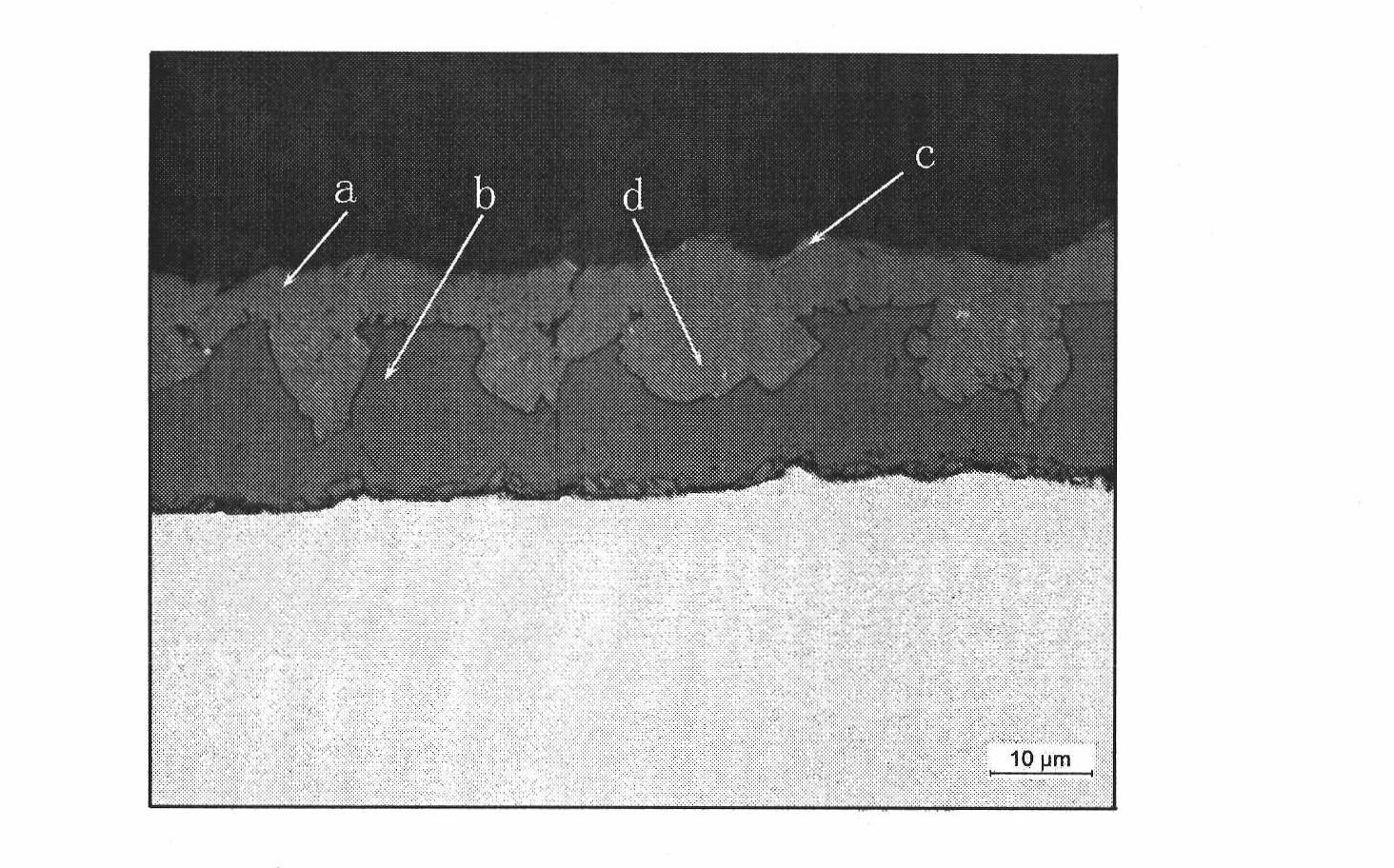

[0030] The sample is a hot-rolled steel strip of SPHC steel heated to 1000°C, cooled to 500°C, held in air for 1000s, and directly quenched to room temperature. The cross-section is cut on the hot-rolled steel strip by the wire cutting method, and the acetone is used as the cleaning liquid to clean the cross-section by ultrasonic waves to remove surface oil.

[0031] The ultrasonic frequency is 40kHz, and the cleaning time is 15min.

[0032] Using the hot inlay method, the hot-rolled steel strip and the inlay material EPOMET_G were inlaid together to expose the cross section. The pressure condition was 290MPa during the inlay, the heating time was 1min, and the inlay was cooled for 3 minutes and taken out to obtain the inlay sample.

[0033] Use 800#, 1000#, 1200# and 1500# sandpaper to grind the section in sequence, using water as the medium, and grinding in the same direction until the scratches on the section are in the same direction. Grinding direction as figure 1 As sh...

Embodiment 2

[0039] The sample is the hot-rolled steel strip of TG510L automobile frame steel, finished rolling at 890°C and coiled at 570°C. The cross-section is cut on the hot-rolled steel strip by the wire cutting method, and the acetone is used as the cleaning liquid to clean the cross-section by ultrasonic waves to remove surface oil.

[0040] The ultrasonic frequency is 50kHz, and the cleaning time is 10min.

[0041] Using the hot inlay method, the hot-rolled steel strip and the inlay material EPOMET_G were inlaid together to expose the cross section. The pressure condition was 280MPa during inlay, the heating time was 1min, and the inlay sample was taken out after cooling for 4 minutes.

[0042] Use 800#, 1000#, 1200# and 1500# sandpaper to grind the section in sequence, using water as the medium, and grinding in the same direction until the scratches on the section are in the same direction.

[0043] The cross-section of the inlaid sample was polished for 8 minutes with abrasive pas...

Embodiment 3

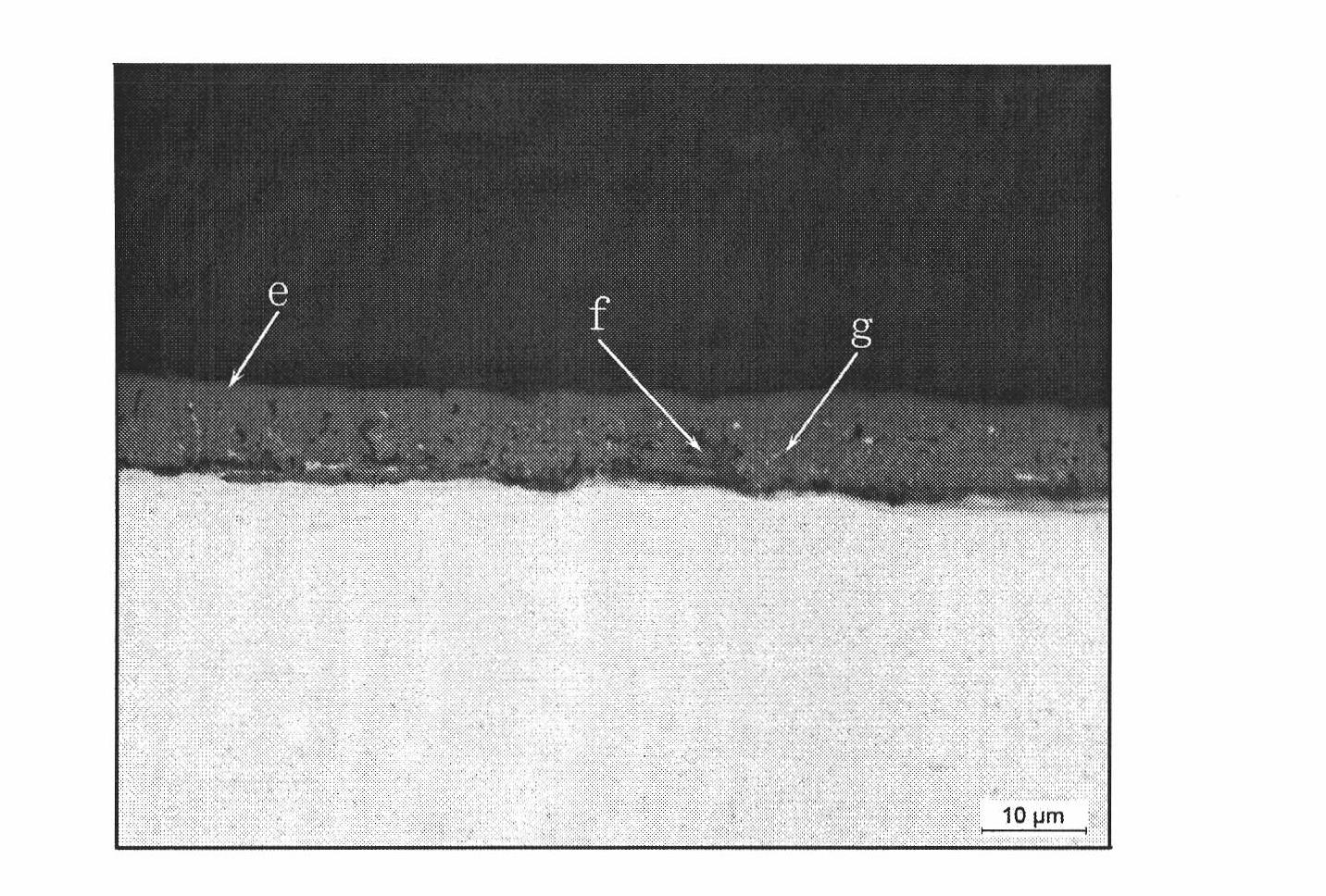

[0048] The sample is a hot-rolled steel strip that is SPHC steel heated to 1000°C, cooled to 450°C, kept under vacuum for 100s, and directly quenched to room temperature. The cross-section is cut on the hot-rolled steel strip by the wire cutting method, and the acetone is used as the cleaning liquid to clean the cross-section by ultrasonic waves to remove surface oil.

[0049] The ultrasonic frequency is 60kHz, and the cleaning time is 5min.

[0050] Using the hot inlay method, the hot-rolled steel strip and the inlay material EPOMET_G were inlaid together to expose the cross section. The pressure condition was 270MPa during the inlay, and the heating time was 2min. After inlaying, it was cooled for 5min and taken out to obtain the inlay sample.

[0051] Use 800#, 1000#, 1200# and 1500# sandpaper to grind the section in sequence, using water as the medium, and grinding in the same direction until the scratches on the section are in the same direction.

[0052] The cross secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com