Preparation method of fresh liquid foundation

A technology of liquid foundation and real powder, which is applied in the fields of body powder, pharmaceutical formula, cosmetic preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

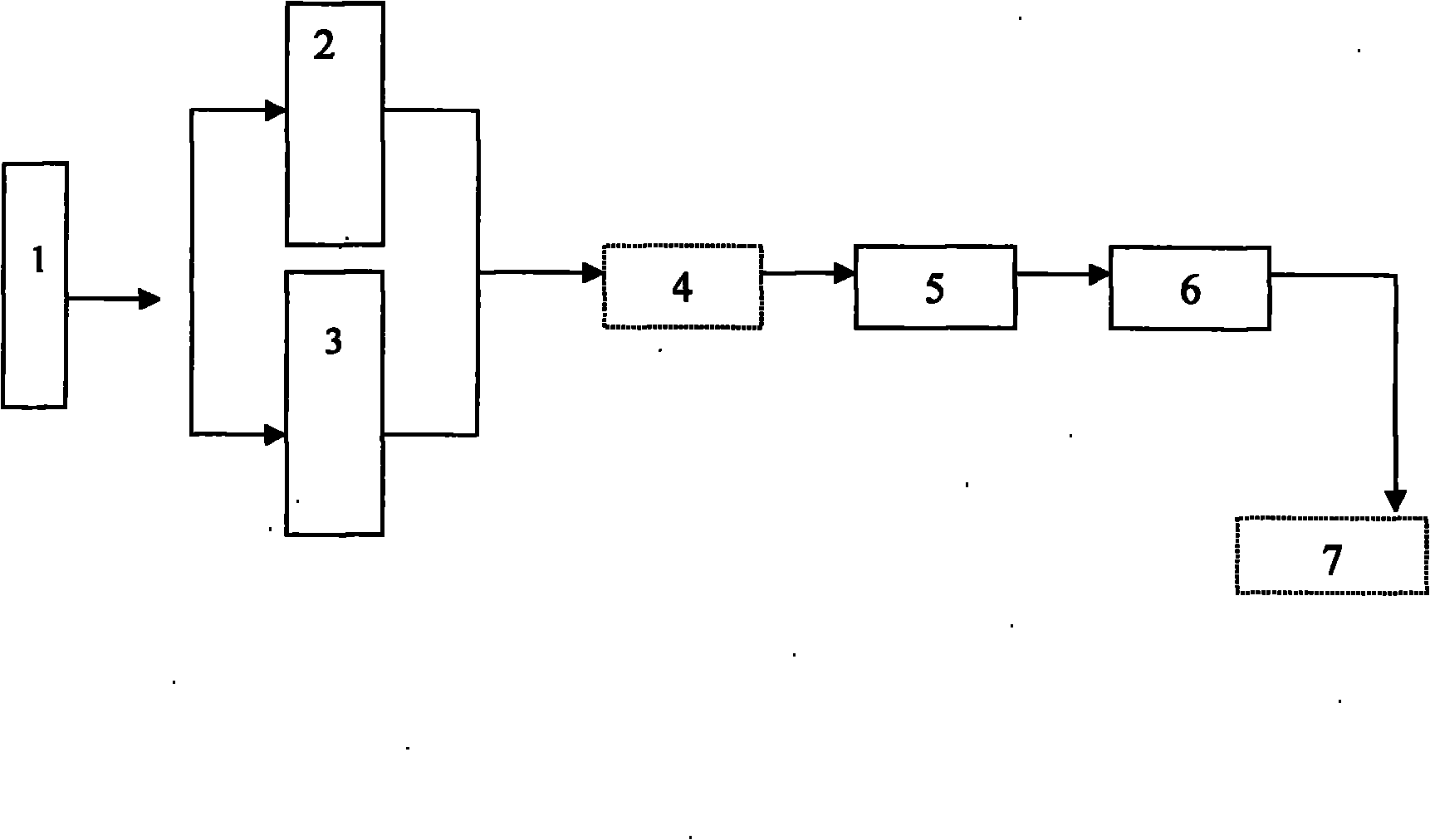

Image

Examples

Embodiment

[0025] Formula: The raw materials for the preparation of liquid foundation are prepared in parts by weight: take 2.3 parts of polyglyceryl-2 oleate and glyceryl stearate, 0.6 part of polyglyceryl-2 polyhydroxystearate, 6 parts of ethylhexyl palmitate part, two C 12 -C 13 1.5 parts of alcohol malate, 3.2 parts of isopropyl myristate, 0.5 parts of magnesium stearate, 0.8 parts of cetyl dimethicone, 0.6 parts of beeswax, 0.15 parts of propylparaben, and myrrh 0.1 part of alcohol, 0.15 part of allantoin, 0.08 part of red iron oxide, 8 parts of titanium dioxide, 19 parts of glycerin, 0.15 part of methyl paraben, 0.5 part of lycopene, 0.10 part of magnesium sulfate, 53 parts of deionized water, Keli essence 0.05 part.

[0026] Its optimal weight portion preparation: 2.5 parts of polyglyceryl-2 oleate and glyceryl stearate, 0.5 part of polyglyceryl-2 polyhydroxystearate, 8 parts of ethylhexyl palmitate, di-C 12 -C 13 2.0 parts of alcohol malate, 3.5 parts of isopropyl myristate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com