Mixed flow expanded bed anaerobic microorganism filter tank

An anaerobic biofilter and biofilter technology, applied in the field of mixed flow expanded bed anaerobic biofilter, can solve the problem of anaerobic suspension filler without pre-hanging film treatment, complex structure of falling water aeration unit, anaerobic suspension Problems such as the small amount of film hanging on the filler, etc., are beneficial to the development of the industry and popularization and application, improve the uniformity of water distribution, and save the effect of aeration power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

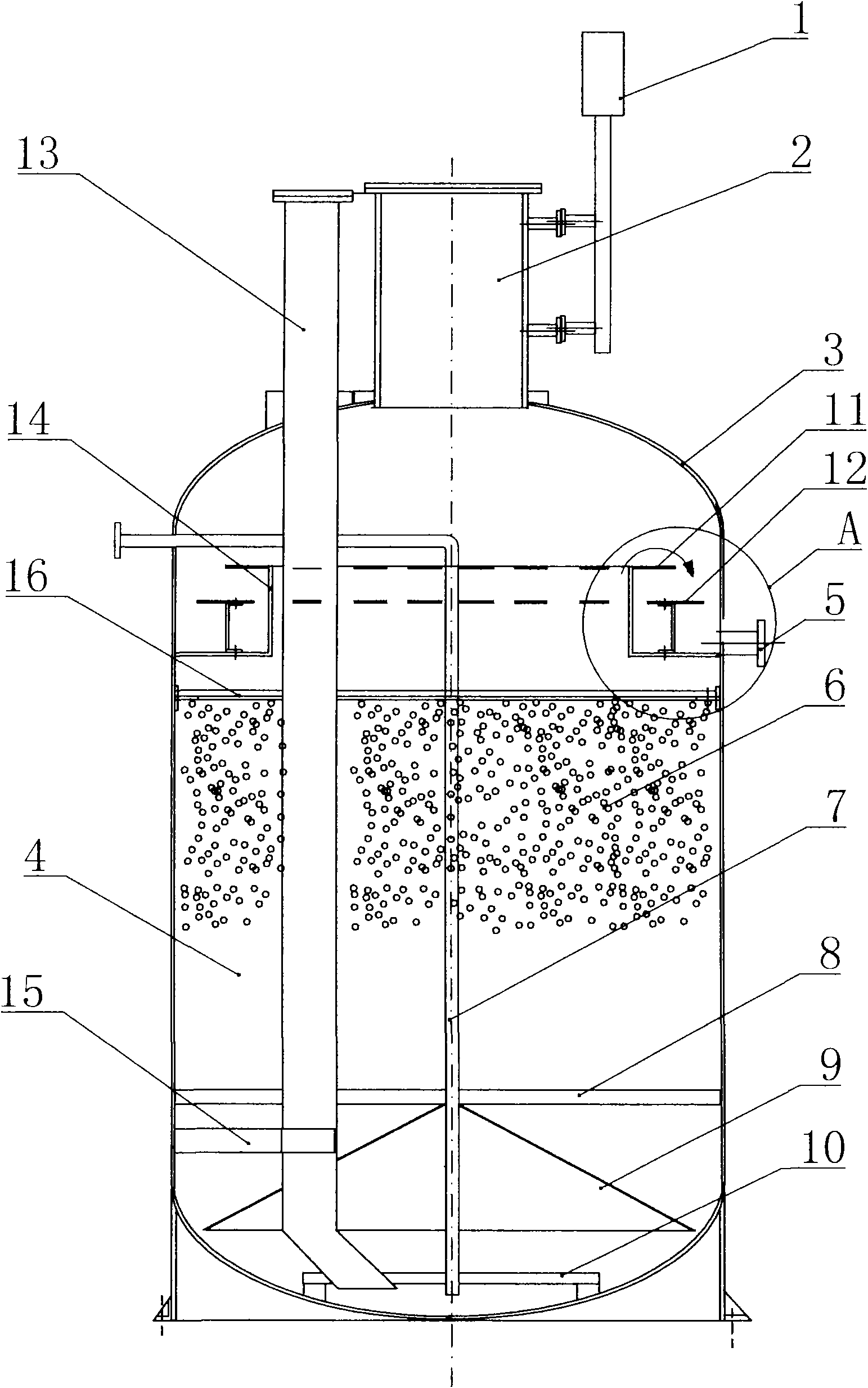

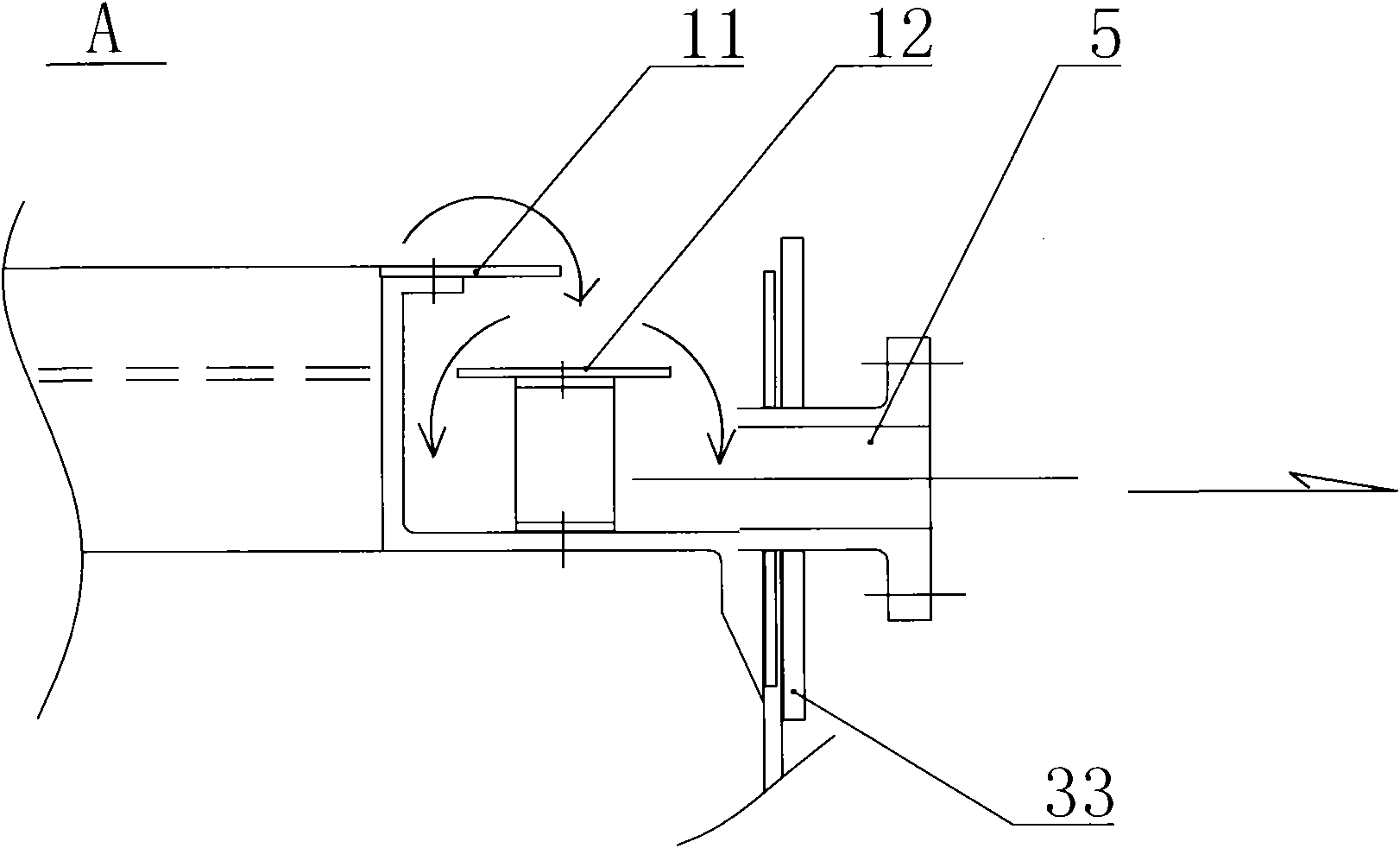

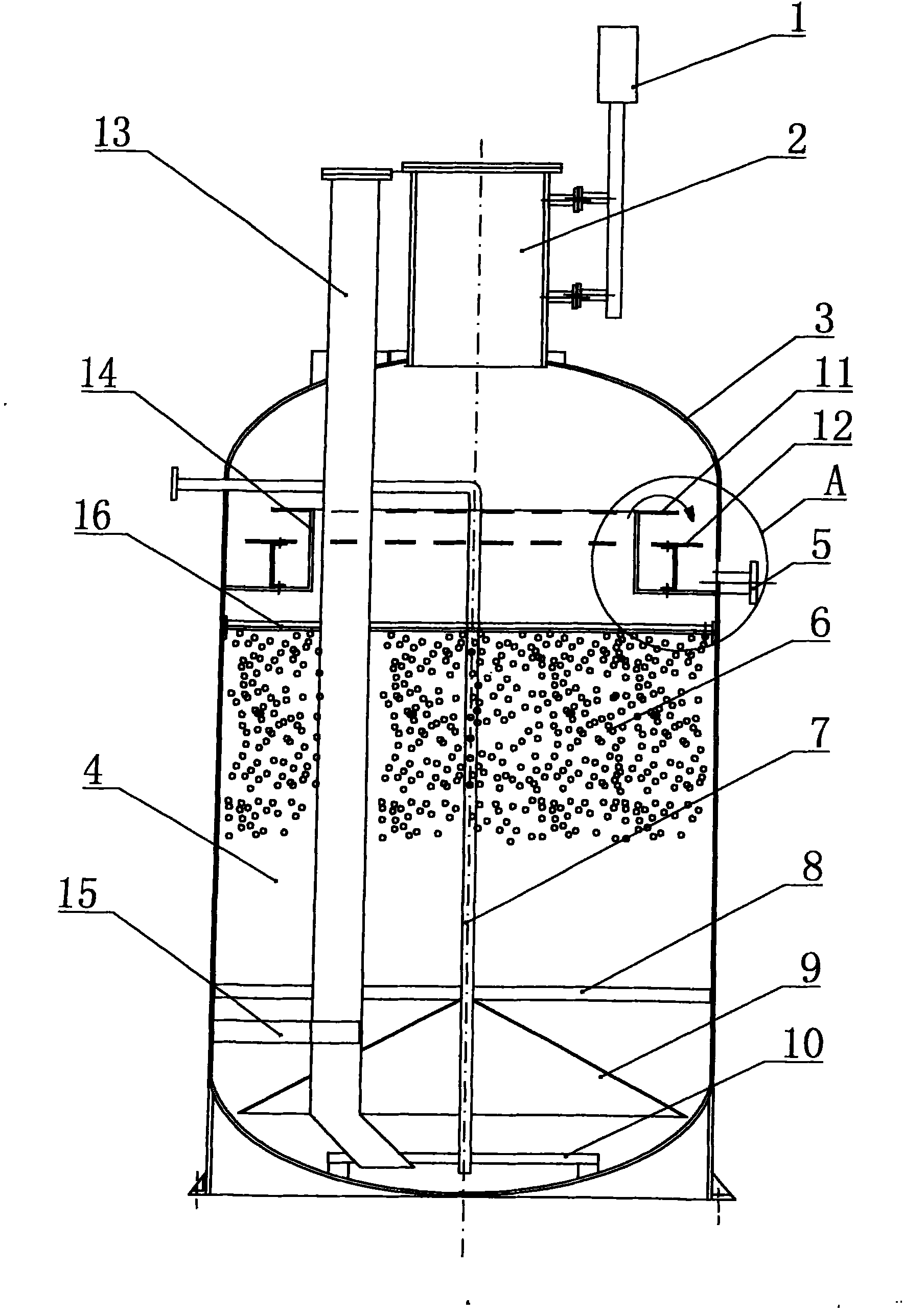

[0024] see figure 1 and figure 2 , the present invention includes a biological filter 4 located in the middle and lower part of the glass fiber reinforced plastic cylindrical tank body 3, a constriction 14 is provided at the upper end of the biological filter 4, and the drop water is provided on the outer edge of the constriction 14 In the aeration unit A, a spacer 16 is arranged in the constriction of the upper end of the biological filter 4 , and an anaerobic suspension filler 6 is arranged below the spacer 16 . A water distributor 9 is installed at the bottom of the biofilter 4, and the water inlet pipe 7 and the dredging pipe 13 are passed longitudinally on the water distributor 9, and the upper ends of the water inlet pipe 7 and the mud suction pipe 13 pass through the described The upper part of the glass fiber reinforced plastic cylindrical tank body 3. The mud suction pipe 13 can conveniently extract excess sludge at the bottom of the tank body, and can also be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com