Preparation method of 3,5-difluoro-4-trifluoro-methoxyl bromobenzene

A technology of trifluoromethoxy bromobenzene and difluorophenol is applied in the field of preparation of TFT liquid crystal intermediates, and can solve the problems of poor atom economy, potential safety hazards, long reaction steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of 2,6-difluoro-4-bromophenol

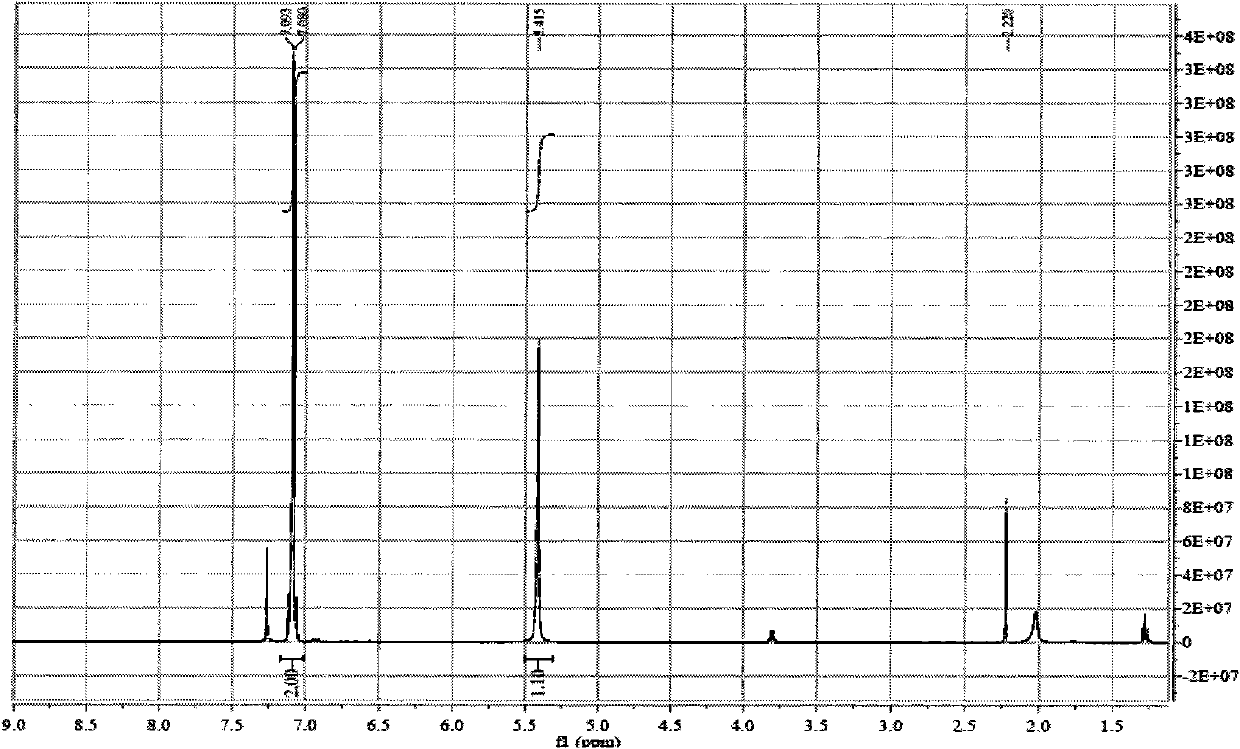

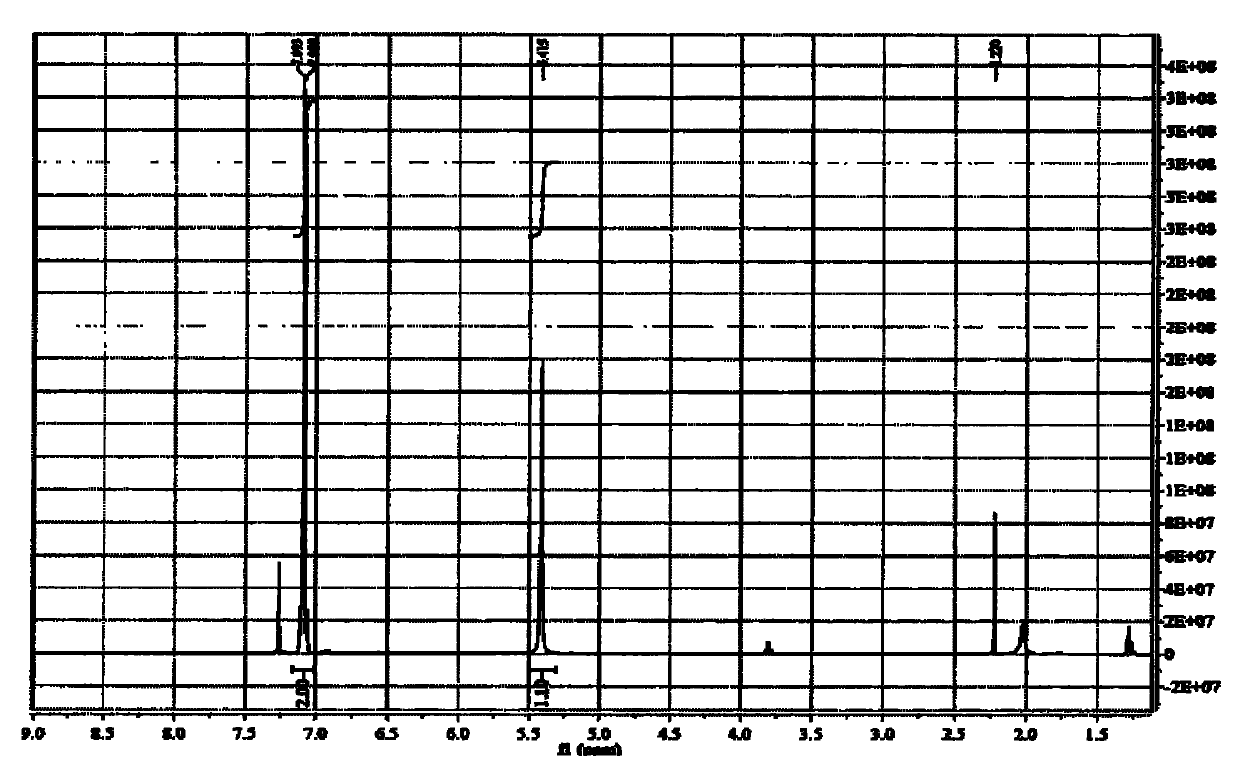

[0022] Put 300g (2.31mol) of 2,6 difluorophenol and 1000g of carbon tetrachloride into a 2000ml four-neck flask, cool to 22°C, and start to drop 555g (3.47mol) of bromine and 800g of carbon tetrachloride solution. The dropwise addition is exothermic, and the temperature of the system is controlled at 20-22°C, and the temperature is kept for 1 hour after the addition is completed. Stop the reaction, add 500ml of water to the system, add 52g of sodium sulfite to eliminate excess bromine, let stand to separate layers, extract the water layer with 150g of carbon tetrachloride, combine the oil layers, and distill the oil layers to obtain 2,6-difluoro-4-bromophenol 432g, content 99.5%, yield 89.6%. Such as figure 1 As shown, NMR data analysis: 1 H-NMR (CDCl 3 , 500Hz) δ: 5.41 (m, 1H), 7.08 (m, 2H).

Embodiment 2

[0023] Embodiment 2: Preparation of 2,6-difluoro-4-bromophenol

[0024] According to Example 1, 1950 g of 1,2-dichloroethane was used instead of carbon tetrachloride to obtain 407 g of 2,6-difluoro-4-bromophenol with a content of 99.0% and a yield of 84.3%.

Embodiment 3

[0025] Embodiment 3: Preparation of 2,6-difluoro-4-bromophenol

[0026] According to Example 1, the amount of bromine was increased to 736g (4.6mol), and the reaction gave 434g of 2,6-difluoro-4-bromophenol with a content of 89.0% and a yield of 90.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com