Multi-functional nanometer oil well cement slurry

A technology of oil well cement slurry and cement slurry, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of large specific surface area of nano-particles, chemical adsorption activity, insufficient use of nano-material advantages, and cement slurry system. problems such as poor flow performance, to achieve the effect of reducing formation water corrosion, ensuring national energy strategy security, and improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment:

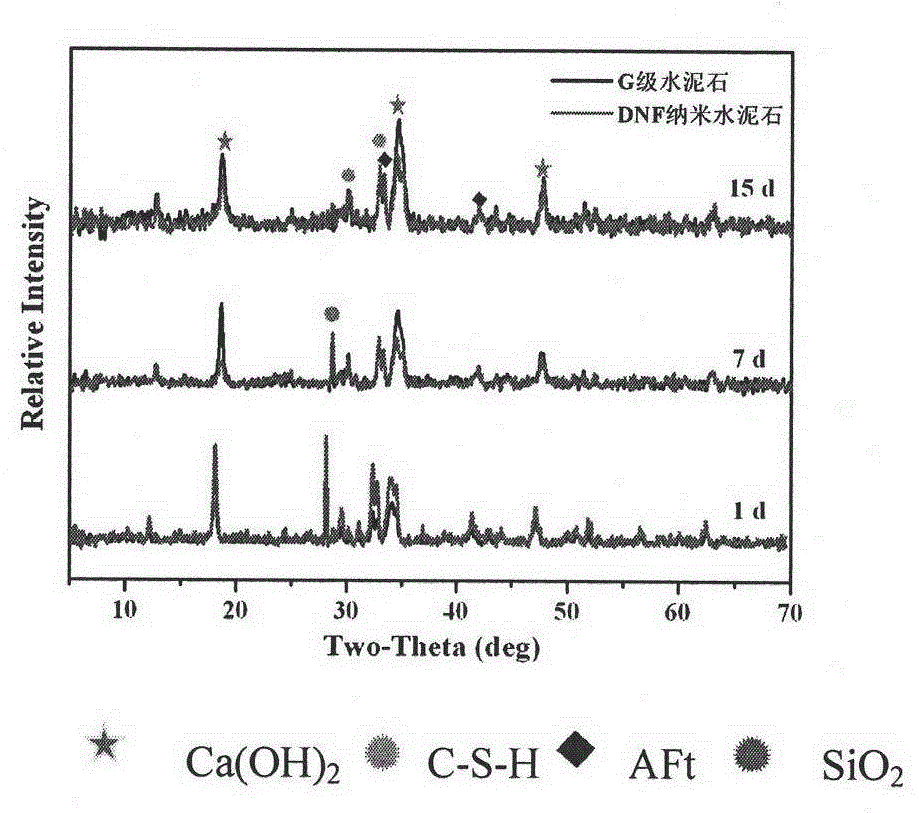

[0013] Taking G-grade oil well cement as an example, the DNF nano-cement slurry system was prepared, and various properties of the system were studied.

[0014] Through surface modification and chemical grafting, the present invention improves the defect that traditional nanomaterials are easy to agglomerate and difficult to disperse, improves the mixing properties of nanoparticles, and ensures the flow performance of the nano-cement slurry system, as shown in Table 1 below.

[0015] Rheology of cement slurry system Table 1

[0016]

category

Liquidity

cm

Φ

300

Φ

100

Φ

3

n

K

Pa·S n

τ s

Pa

Q c

l / s

P f

MPa

G grade puree

24

99

71

18

0.39

3.73

9.20

98.50

0.88

DNF grout

26.5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com